Nondestructive testing method for mixing amount of steel fibers in concrete

A non-destructive testing, steel fiber technology, applied in the direction of measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the limitation of steel fiber content, non-destructive testing of steel fiber concrete structure can not be quantitatively detected, affect the service life of concrete structures and Durability and other issues to achieve the effect of controlling construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

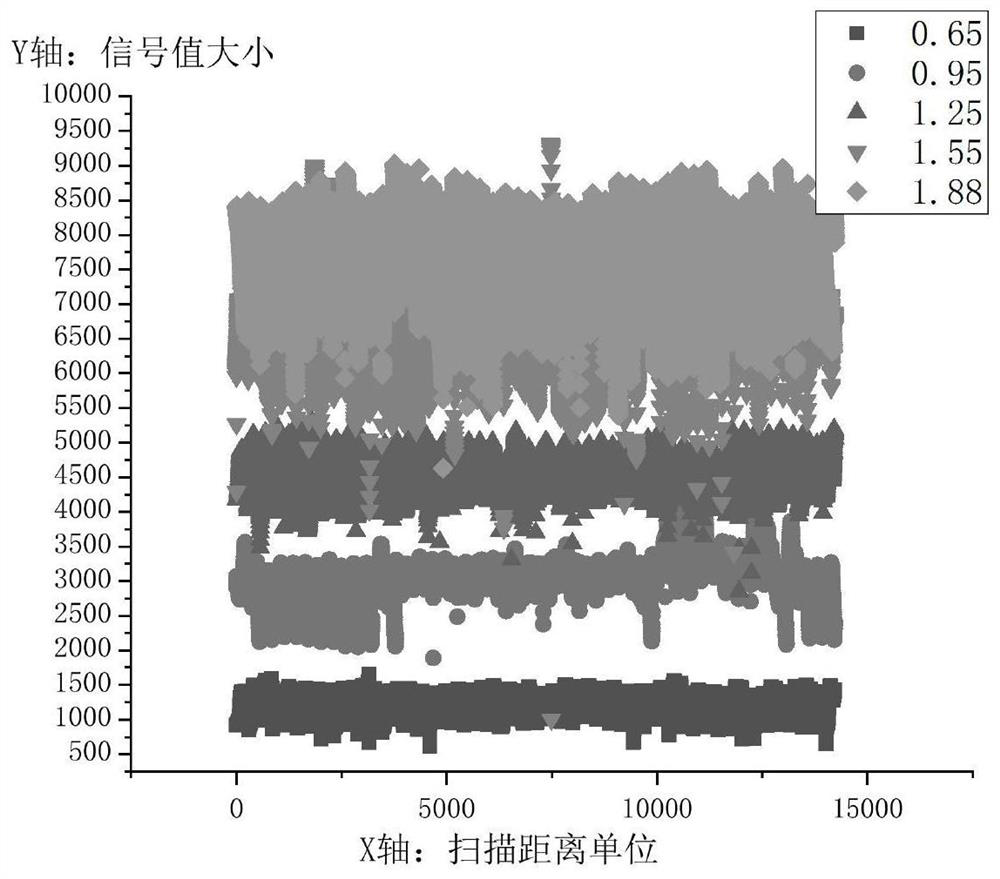

[0031] (A1) Factory prefabricated concrete standard specimens with different steel fiber content (0.65, 0.95, 1.25, 1.55, 1.88%);

[0032] (A2) Use the steel bar scanner to scan the prefabricated steel fiber reinforced concrete standard specimen;

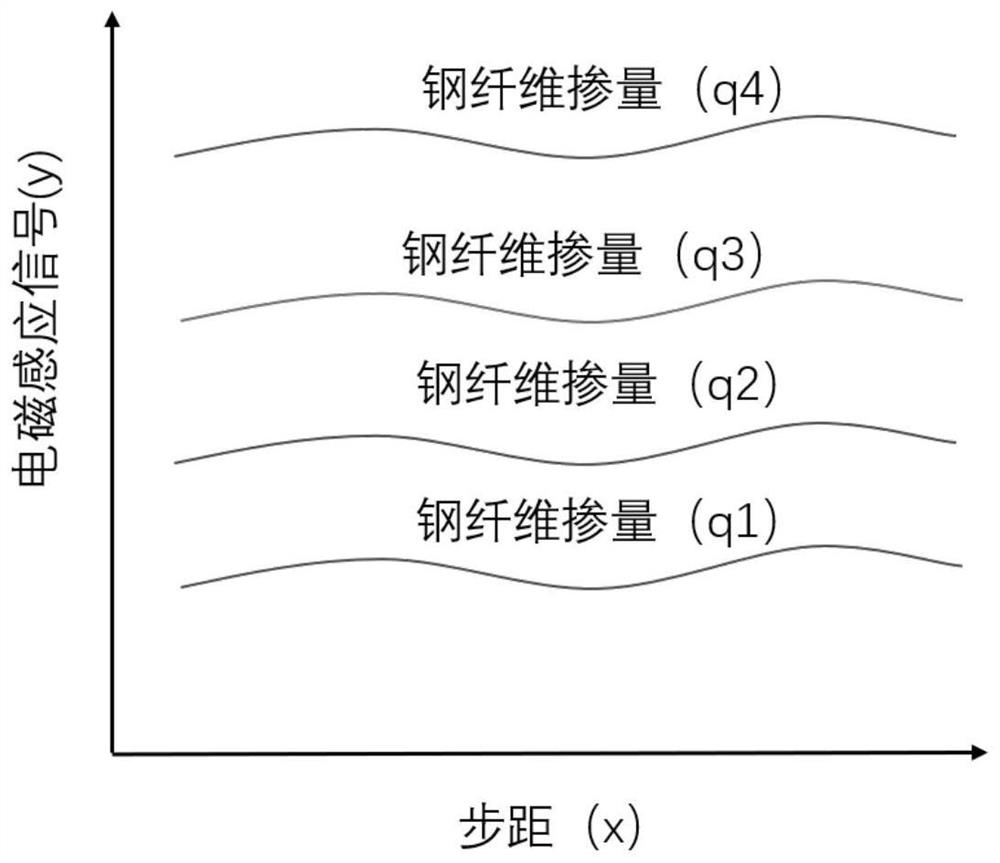

[0033] (A3) Obtain signal diagrams corresponding to different steel fiber precast concrete standard specimens ( image 3 );

[0034] (A4) Repeat steps A1 to A3 to obtain a sufficient number of signal diagrams corresponding to known steel fiber precast concrete standard specimens;

[0035] Further, mathematical statistical methods are used to preprocess and extract the features of the waveform signal graph, and obtain the average value of electromagnetic signals (y1, y2, y3...) corresponding to different steel fiber content.

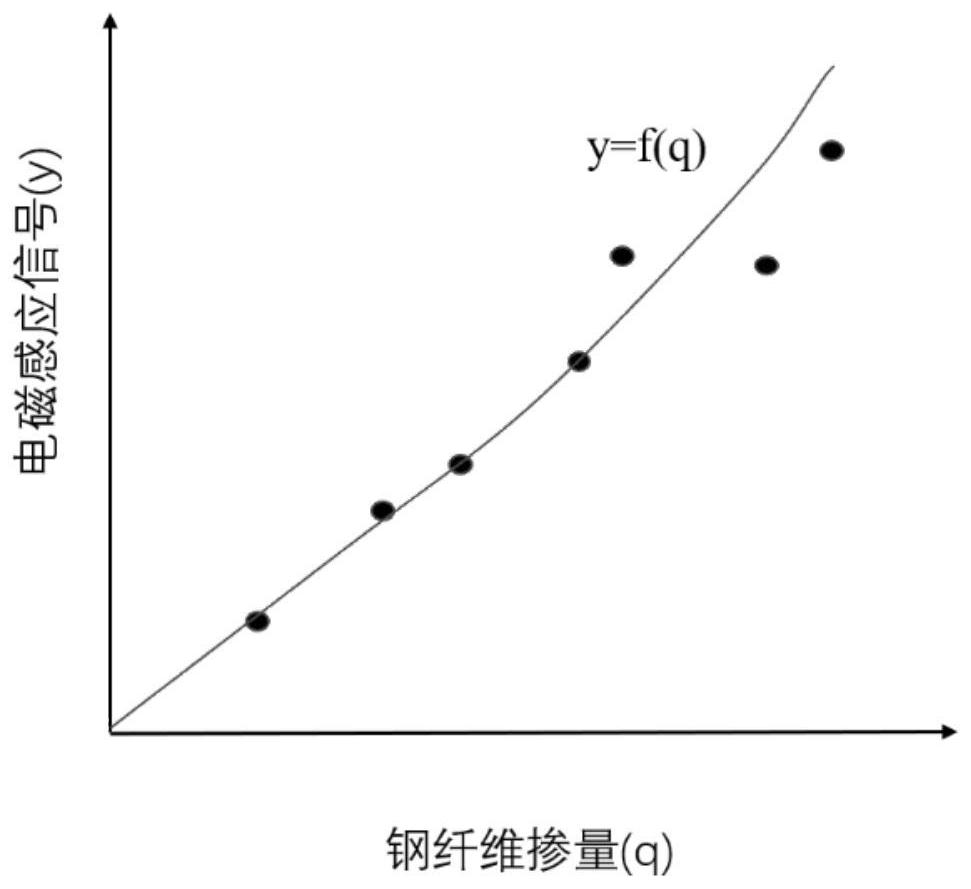

[0036] Through nonlinear fitting, the relationship function between steel fiber content and electromagnetic signal value is obtained and drawn,

[0037] y=591.93+7174.05x+686.50x 2 +2647.49x 3 .

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com