A Gapless Weld Seam Recognition Method and System Based on a Line Scan Camera

A technology of a line scan camera and a recognition method, applied in manufacturing computing systems, image analysis, image enhancement, etc., can solve problems such as low processing efficiency, inability to identify extremely narrow gaps and gapless welds, and data redundancy. , to achieve the effect of avoiding information redundancy, reducing data operations, and quickly deleting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the description of the present invention, it should be understood that the orientation description is involved, such as up, down, front, back, left, right, etc.

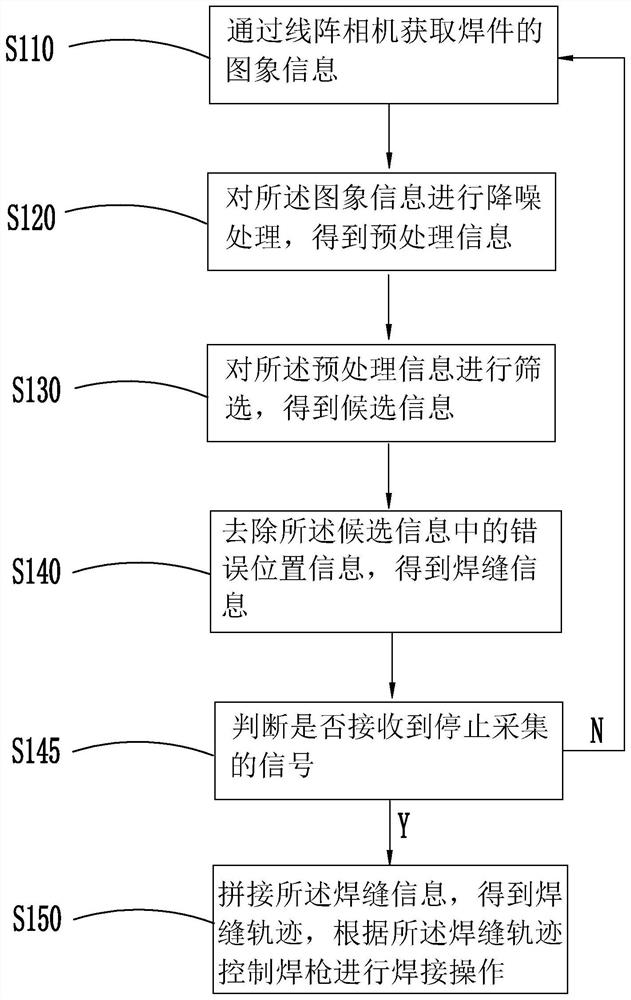

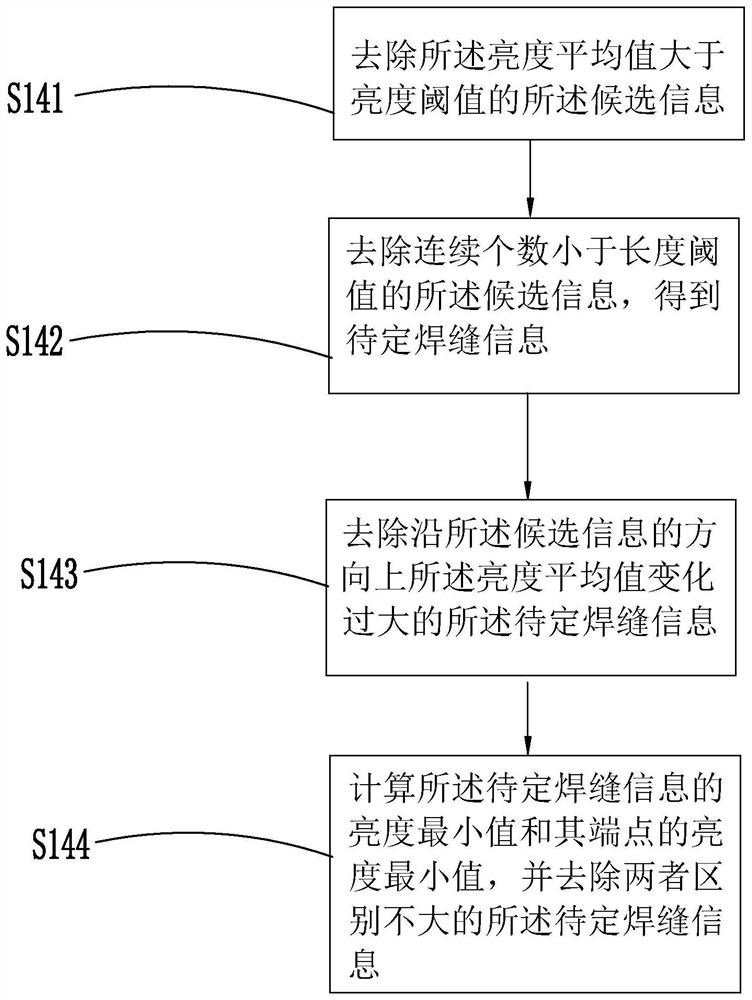

[0032] By performing noise reduction and screening processing on the image information, the information amount of the image information can be effectively reduced, and the production of

[0034] In this embodiment, the line frequency of the line scan camera 210 is 29000 lines / second, and the resolution is 4096*1 pixels. for

[0035] L

[0037] L

[0041]

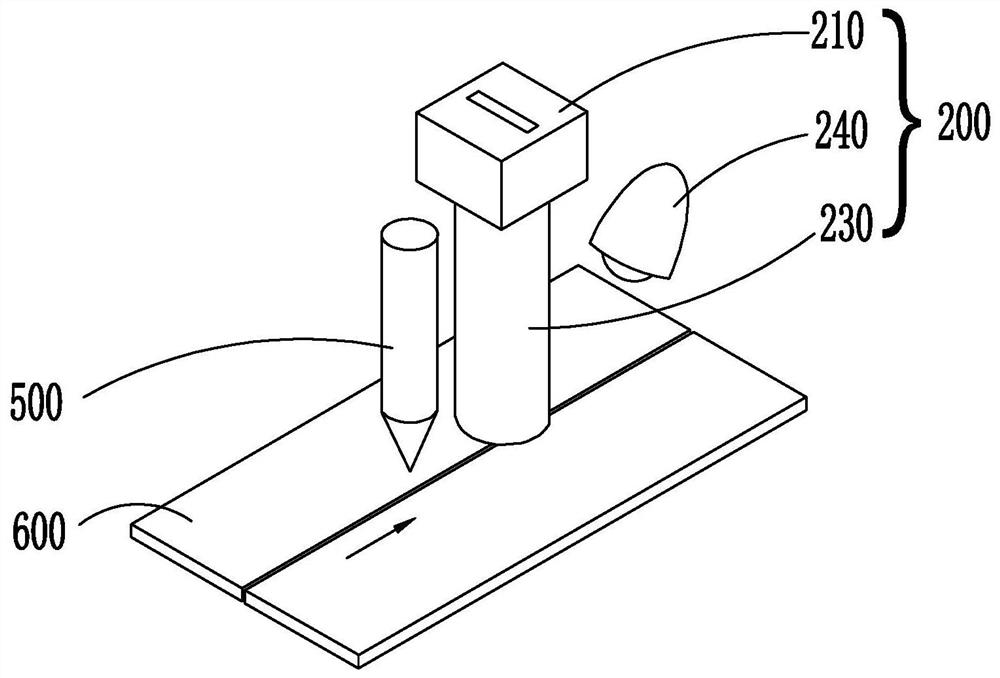

[0056] In another embodiment, the image acquisition unit 200 further includes: an imaging device 230 and an illumination light source 240; the imaging device

[0058] In another embodiment, the image acquisition unit 200 further includes a movable mechanism (not shown in the figure); the movable mechanism drives the linear array

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com