A Thrust Fluctuation Compensated Secondary of Ring Winding Permanent Magnet Linear Synchronous Motor

A technology of permanent magnet linear synchronization and ring winding, which is applied in the direction of magnetic circuit rotating parts, magnetic circuits, electromechanical devices, etc., can solve problems such as large thrust fluctuations, achieve high thrust density, promote engineering practical progress, and easy process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

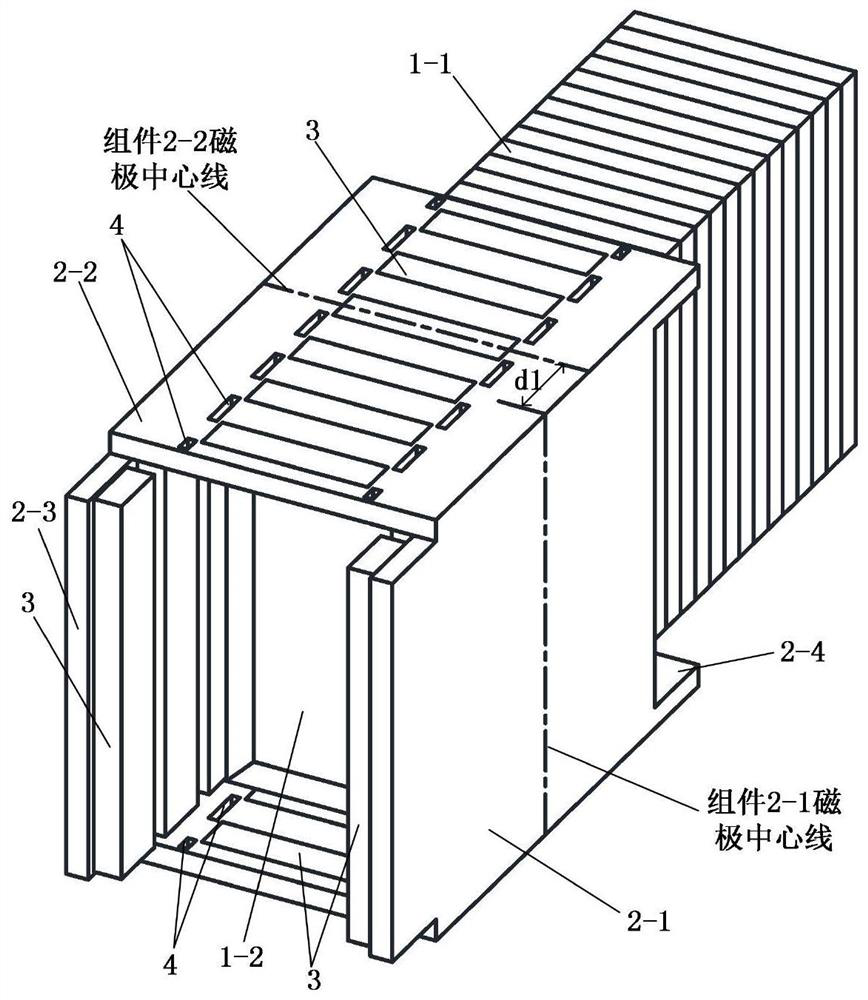

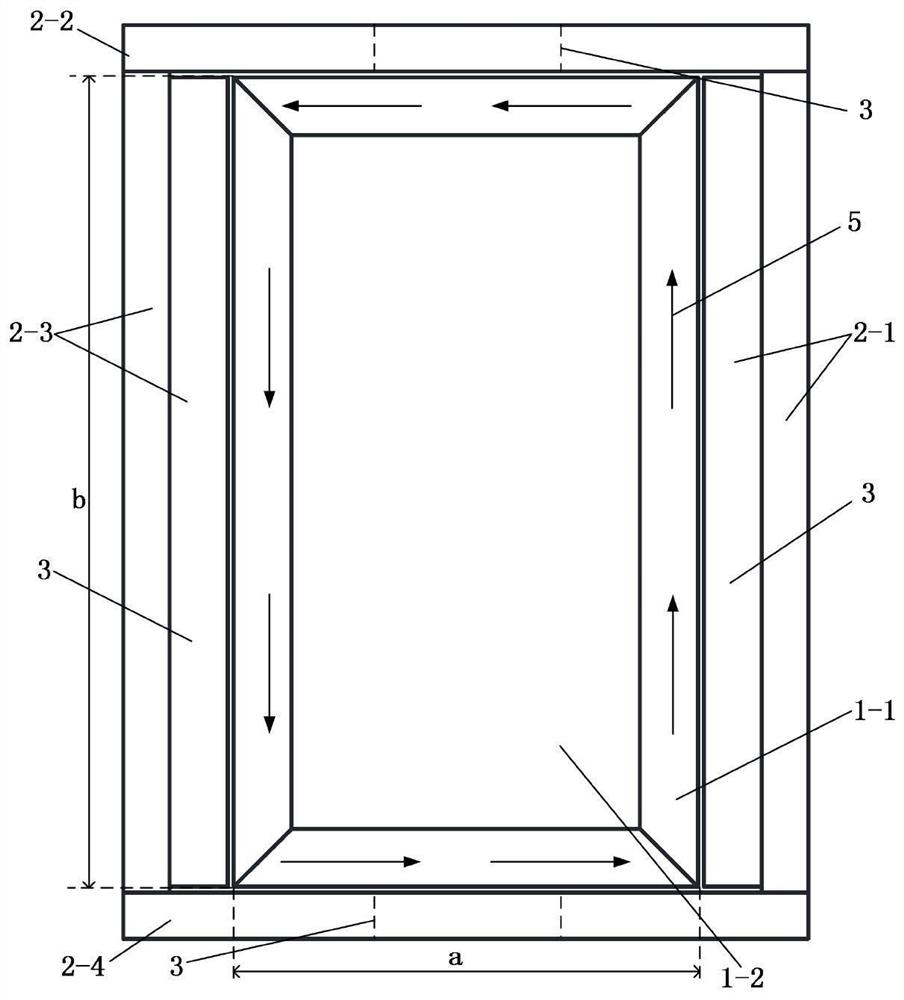

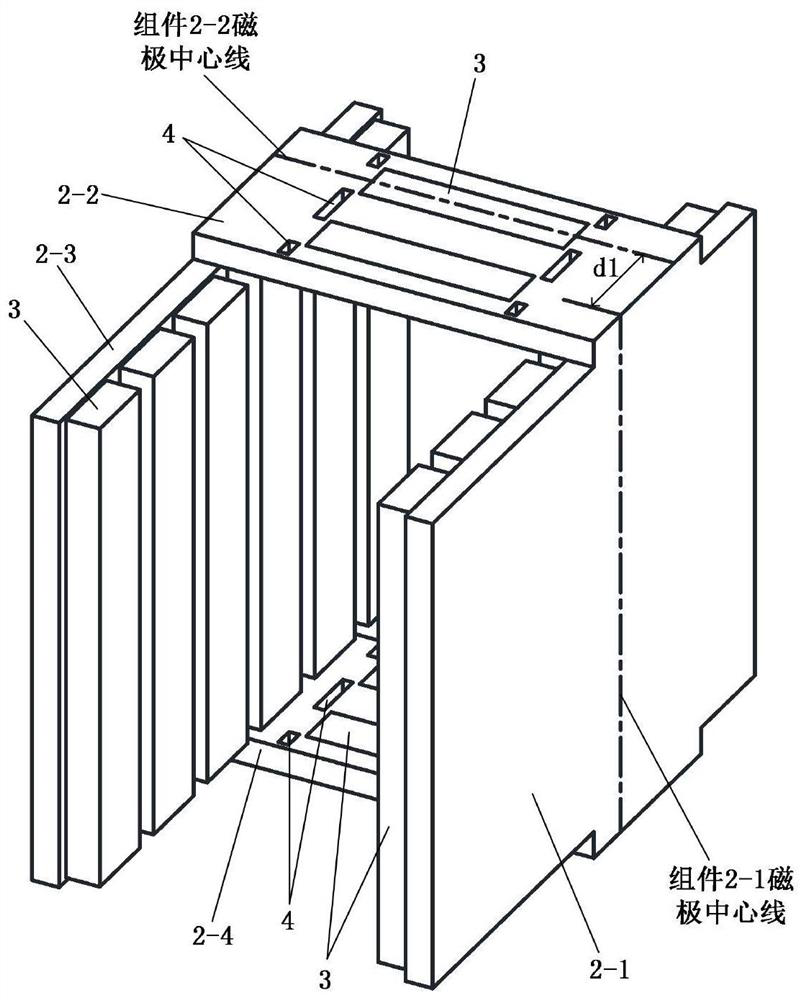

[0030] In this embodiment, as figure 1 and figure 2 As shown, the thrust fluctuation compensation secondary of a ring winding permanent magnet linear synchronous motor is a four-sided flat plate structure, and the secondary components on each side include a permanent magnet and a magnetic yoke plate. Among them, the permanent magnets in the first flat-type secondary assembly 2-1 and the third flat-type secondary assembly 2-3 are surface-mounted, and the second flat-type secondary assembly 2-2 and the fourth flat-type secondary assembly 2 The permanent magnets in -4 are in embedded form, the first flat-type secondary assembly 2-1 and the third flat-type secondary assembly 2-3 are mirror-symmetrical structures, the second flat-type secondary assembly 2-2 and the fourth flat-type secondary assembly 2-2 The plate-type secondary assemblies 2-4 are mirror-symmetrical structures. The multi-faceted secondary assembly and the primary armature form a multi-faceted air gap structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com