Environment-friendly building sand making equipment

An environmentally friendly and architectural technology, which is applied in the fields of dust removal, grain treatment, dispersed particle separation, etc., can solve the problems of cumbersome operation, unreachable, environmental pollution, etc., and achieve the effect of preventing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

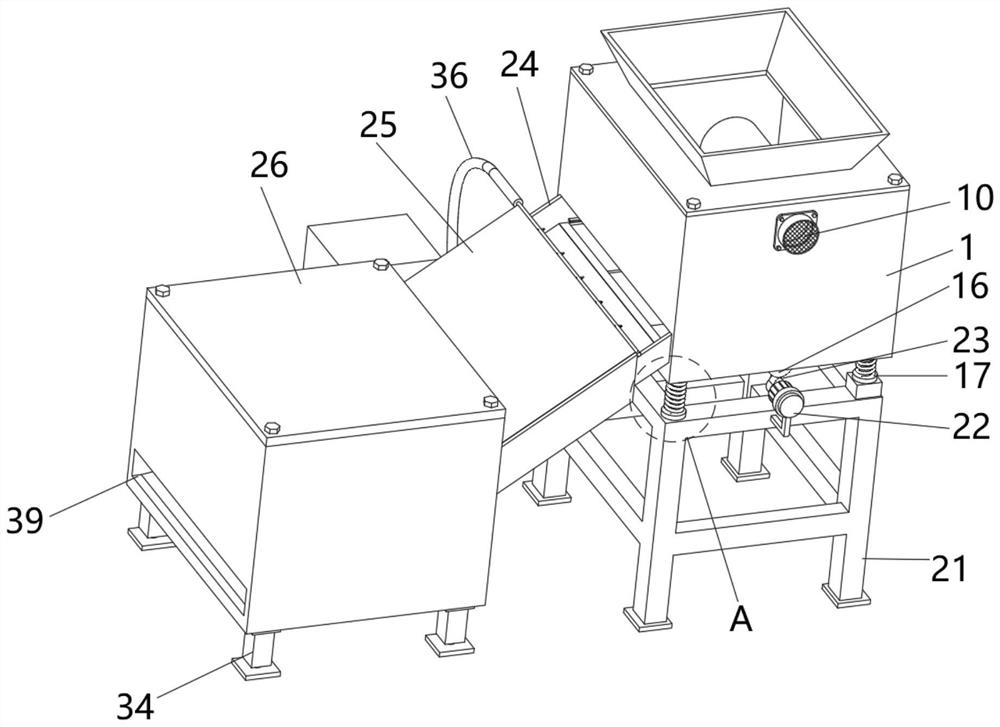

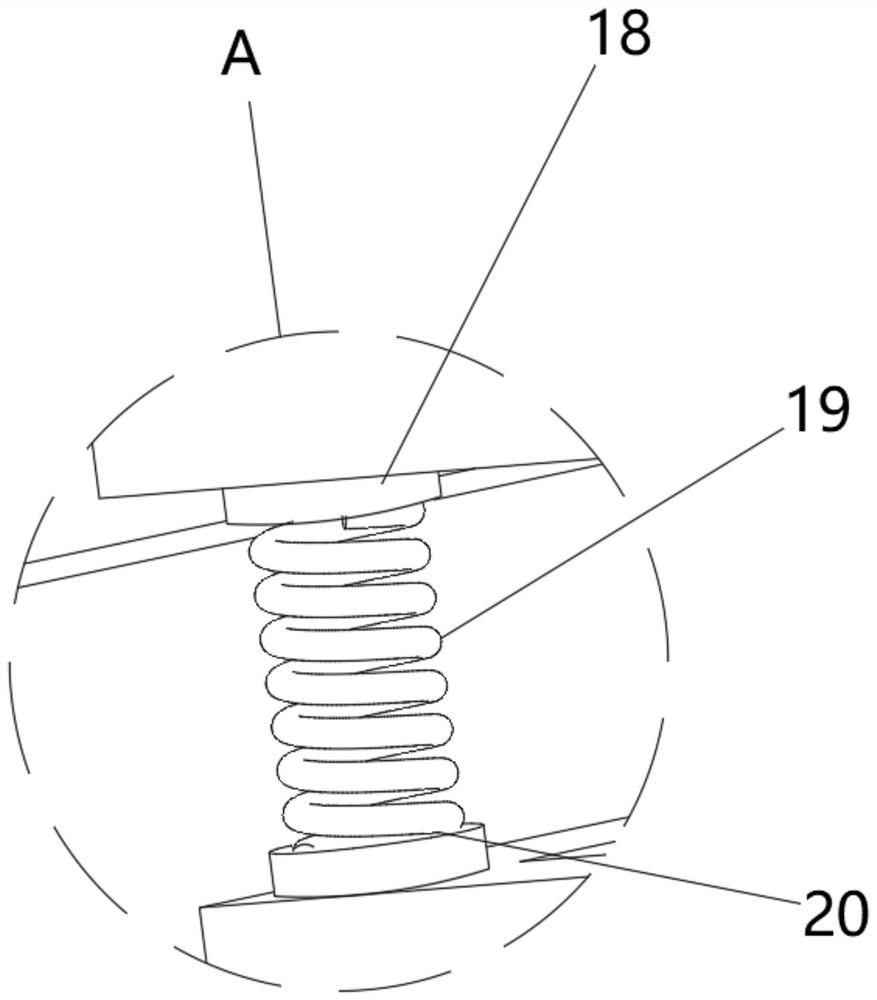

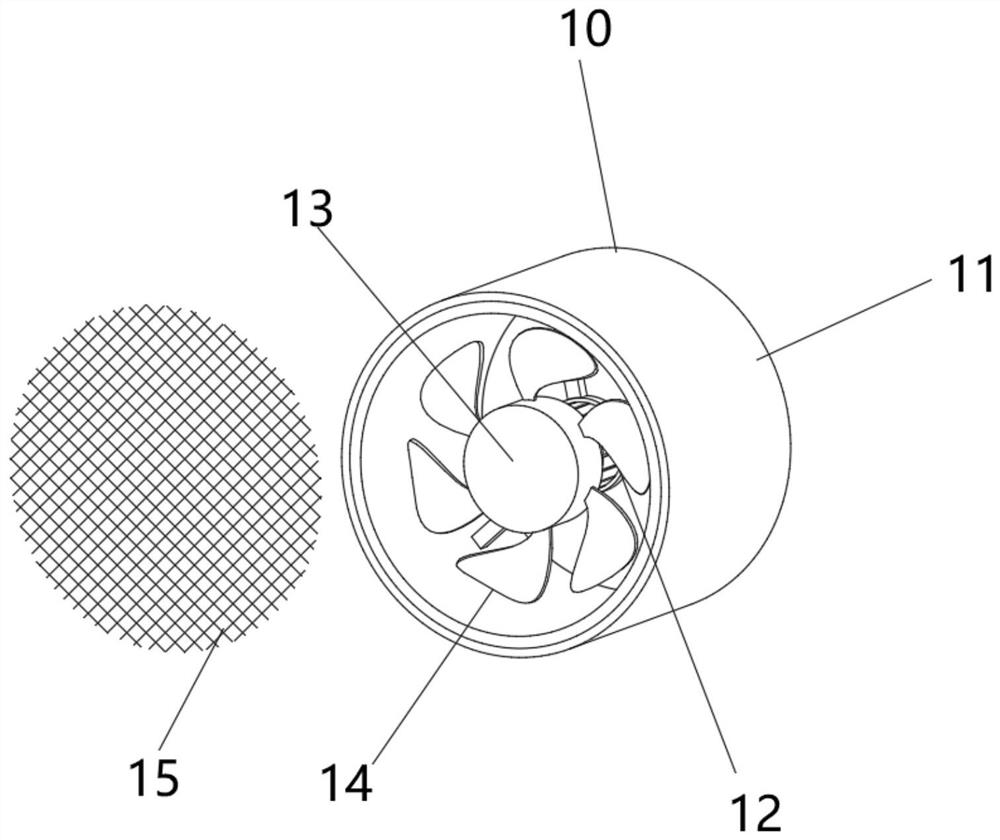

[0026] Example: such as Figure 1-6As shown, an environment-friendly building sand making equipment includes a first crushing box 1, a first belt 6, a second crushing box 26 and a second belt 31, and a first drive motor 2 is installed on one side of the first crushing box 1, The first driving wheel 3 is installed at the output end of the first drive motor 2, and two first rotating columns 4 are rotationally connected in the first crushing box 1. The driving wheel 5 and the two first driven wheels 5 are connected to the first driving wheel 3 through the transmission of the first belt 6, the first crushing wheel 7 is installed on the first rotating column 4, and the leakage screen 8 is installed in the first crushing box 1. 8 is located below the two first crushing wheels 7, a discharge hopper 9 is installed on one side of the first crushing box 1, and the discharge hopper 9 is located below the leakage screen 8, and a dust removal mechanism 10 is installed on one side of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com