Ship segmented spraying robot based on visual guidance

A spraying robot, vision-guided technology, applied in the directions of manipulators, spraying devices, liquid spraying devices, etc., to achieve the effect of increasing the vision-guided function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

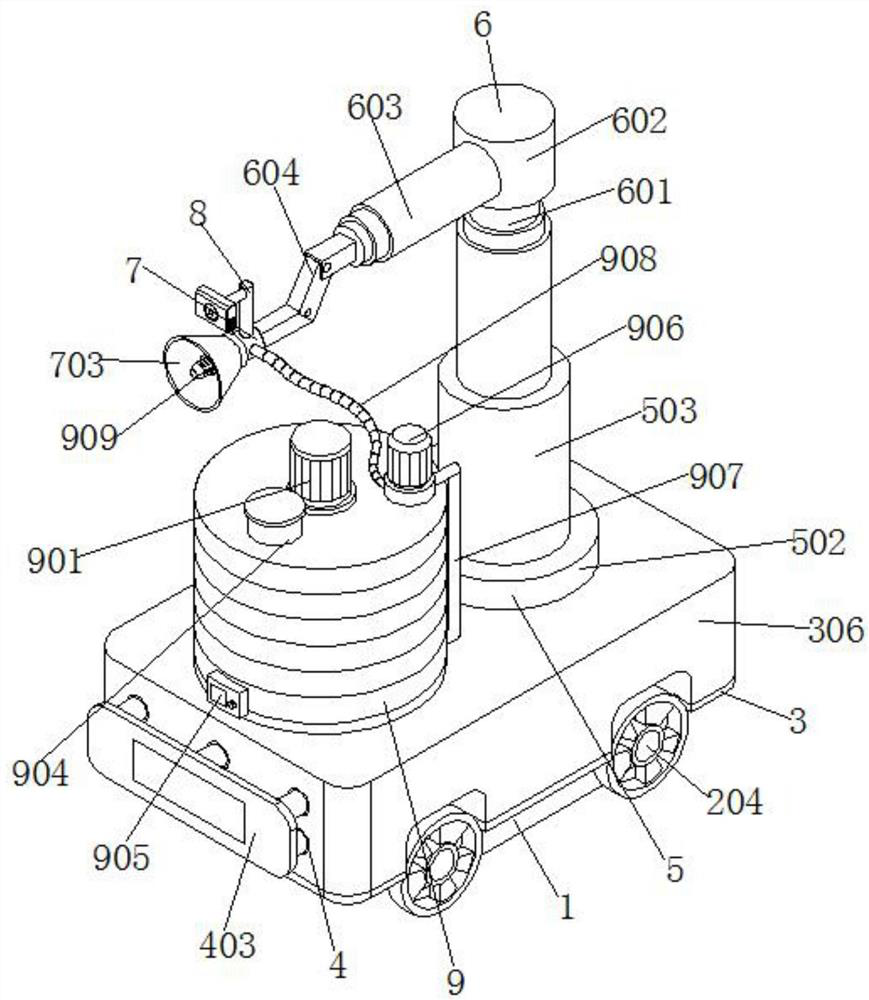

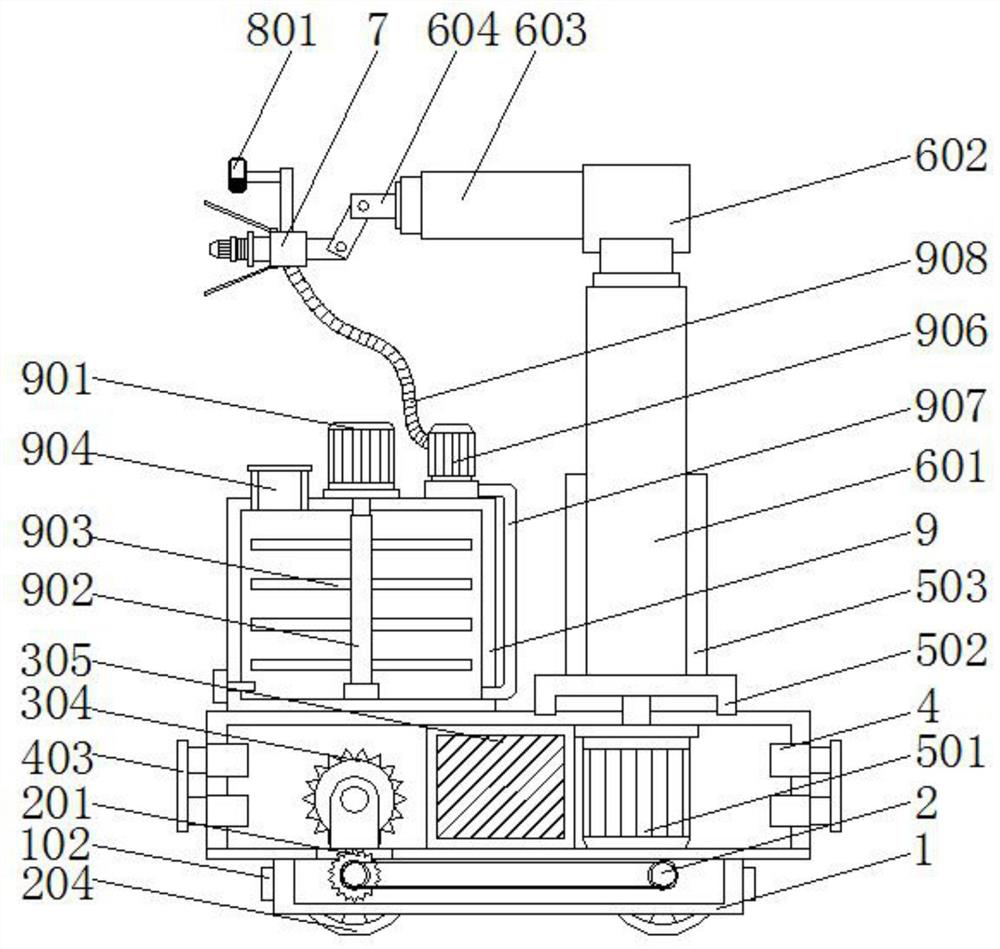

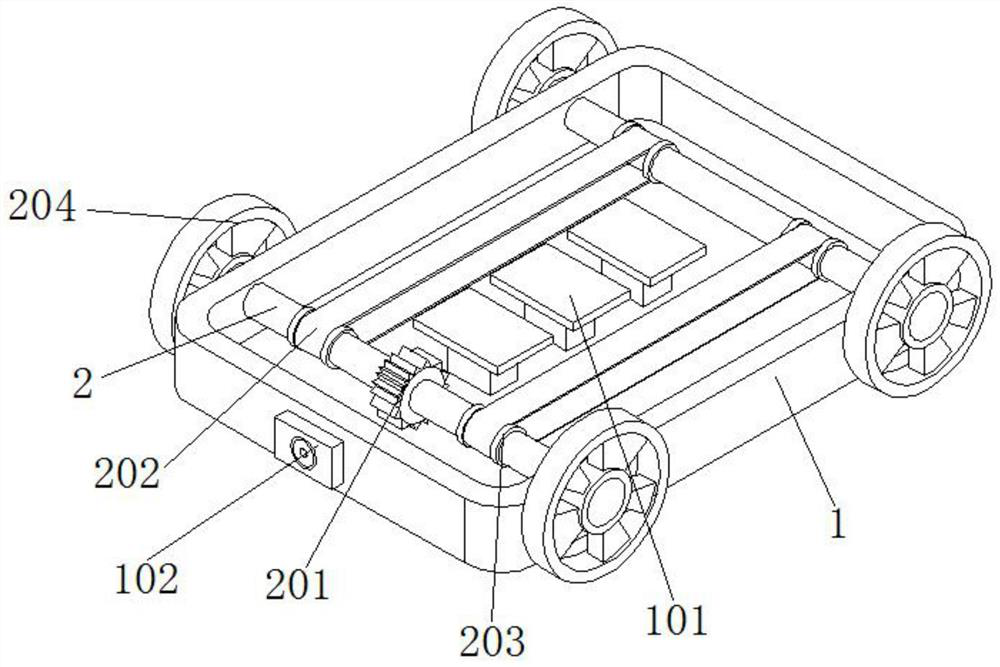

[0039] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a vision-guided marine segmental spraying robot includes a bottom frame 1, a rotating rod 2 and a bottom plate 3. Two groups of rotating rods 2 arranged side by side are installed on the front of the bottom frame 1, and the back of the rotating rod 2 Through the inside of the bottom frame 1, a bottom plate 3 is installed on the top of the bottom frame 1, and a cover frame 306 is installed on the top of the bottom frame 3. A cylinder 4 is installed on both inner walls of the cover frame 306, and one end of the cylinder 4 extends out of the cover. the interior of box 306;

[0040] Specifically, the bottom frame 1 is used to integrate the components installed on the top of its inner box, so that the components interact with each other, the rotating rod 2 can be used for the rotational force, and the bottom plate 3 is used to block the top of the bottom frame 1, so that its interior It forms an independent ...

Embodiment 2

[0050] Such as Figure 8 As shown, the outer surface of the connecting column 7 is equipped with a threaded ring 701, the outer surface of the threaded ring 701 is threaded with an engaging ring 702, and one side of the outer wall of the engaging ring 702 is equipped with a cover plate 703, and the cover plate 703 is installed around the spray coating. The outside of the head 909.

[0051]Specifically, the thread of the threaded ring 701 can be consistent with the internal thread of the connecting ring 702, and the worker can hold the cover plate 703, align it with the connecting column 7 as a whole combined with the connecting ring 702, and then apply rotation to it. Power, impels the inner thread of the connecting ring 702 to fit with the threaded ring 701, which can facilitate the installation of the cover plate 703 on the outside of the spraying head 909. During the spraying operation, it can be used to block the spraying range and avoid spraying from the spraying head 909...

Embodiment 3

[0053] Such as Figure 7 As shown, an inverted L-shaped fixed rod 8 is installed on the top of the connecting column 7 , and a camera 801 is installed at one end of the inverted L-shaped fixed rod 8 , and the camera 801 is located above the cover plate 703 .

[0054] Specifically, the inverted L-shaped fixed rod 8 is used to install the camera 801. The camera 801 has functions such as taking pictures and recording videos. It is located above the spraying head 909. When the spraying head 909 is driven by the movable structure 6 to spray from bottom to top The area to be sprayed can be photographed by the camera 801 first, and then the photographed picture is transmitted to the processing component 305 electrically connected to it, and the processing component 305 judges whether spraying is possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com