Thin-wall aluminum pipe stretching and expanding connection forming device and technology thereof

A forming device and expansion technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of pipe distinction, plastic deformation and damage of pipes, avoid errors in manual judgment, freely adjust the degree of expansion, The effect of reducing the degree of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

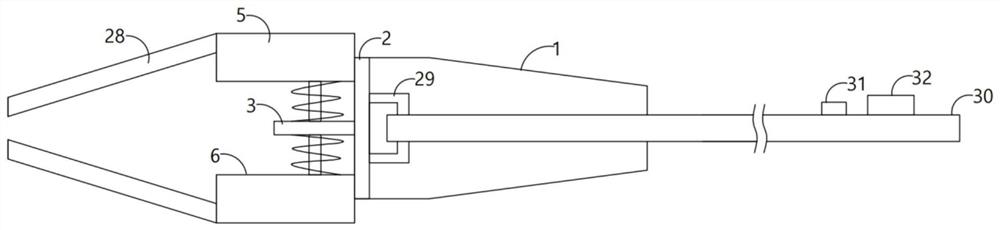

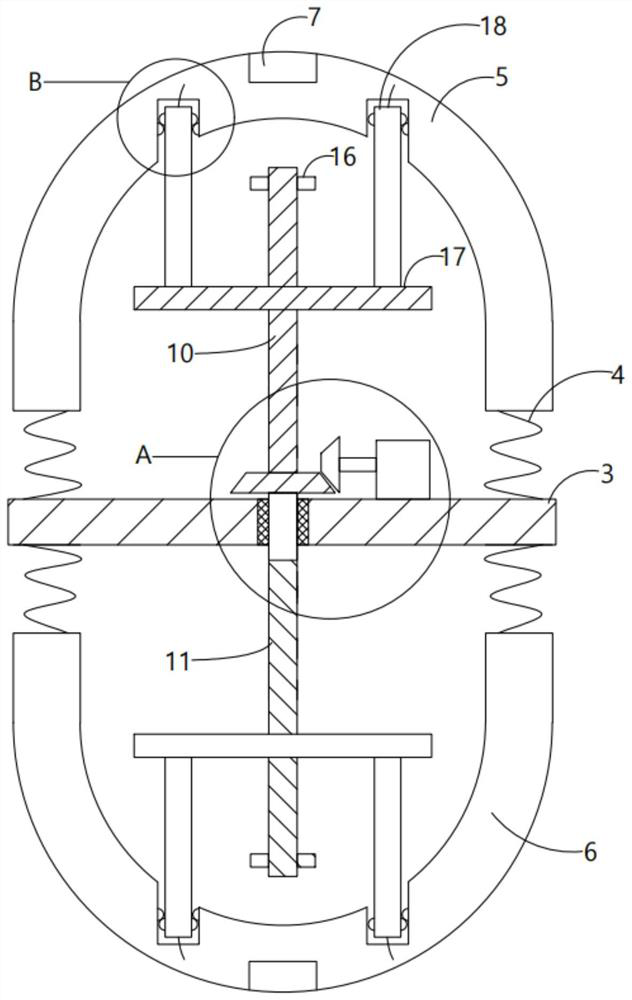

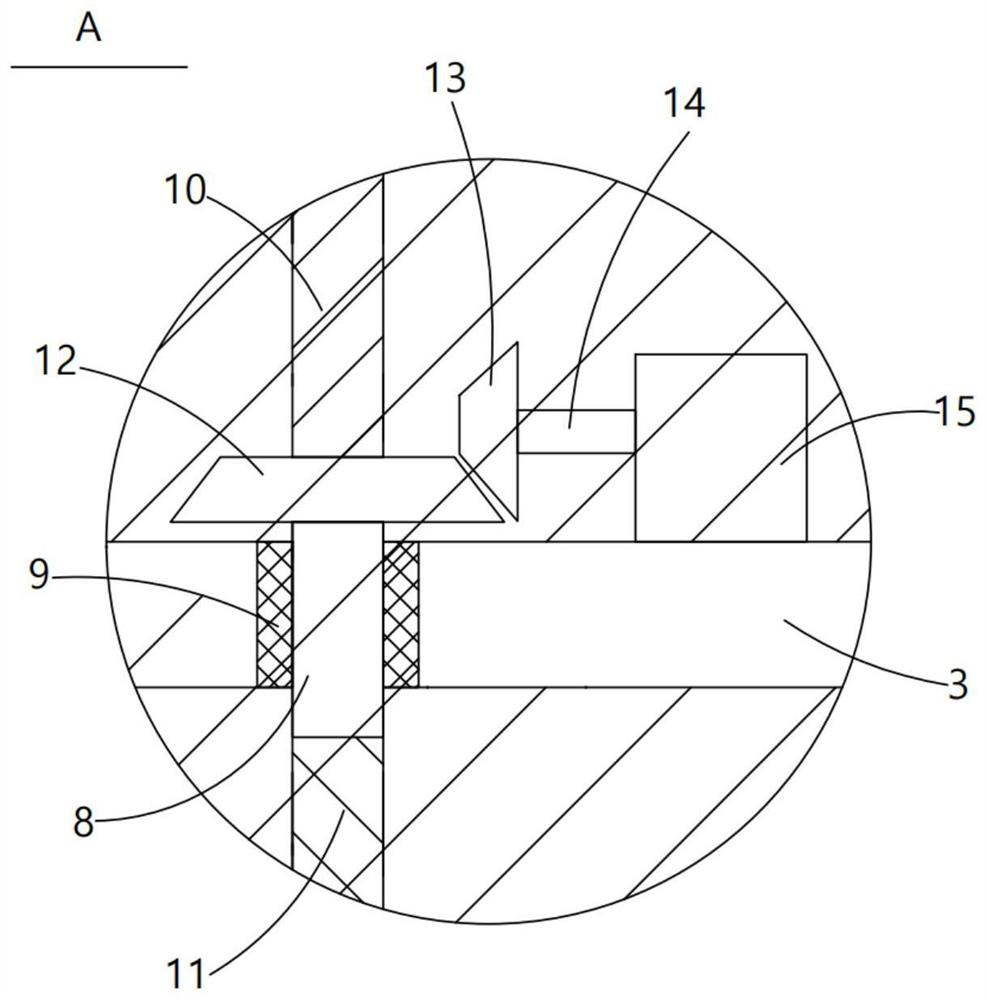

[0039] see Figure 1 to Figure 6 , the present invention provides a technical solution:

[0040] A thin-walled aluminum tube stretch expansion forming device, comprising:

[0041] Positioning tube 1, the end of the positioning tube 1 is fixedly provided with a sealing plate 2, the middle position of the sealing plate 2 away from the side of the positioning tube 1 is fixedly provided with a partition 3, and the two sides of the partition 3 are symmetrically connected and provided with a first spring 4. An upper expansion plate 5 and a lower expansion plate 6 are respectively connected to the first springs 4 on both sides. Both the upper expansion plate 5 and the lower expansion plate 6 are arc-shaped and made of hard materials.

[0042]Rotating rod 8, rotating rod 8 is hinged to be arranged in dividing plate 3, so rotating rod 8 can rotate in situ, and the two ends of rotating rod 8 are respectively fixedly provided with upper screw mandrel 10 and lower screw mandrel 11, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com