A kind of brass valve processing method

A processing method, brass valve technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low grinding speed and efficiency, achieve the effect of optimizing the processing sequence and improving the processing speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

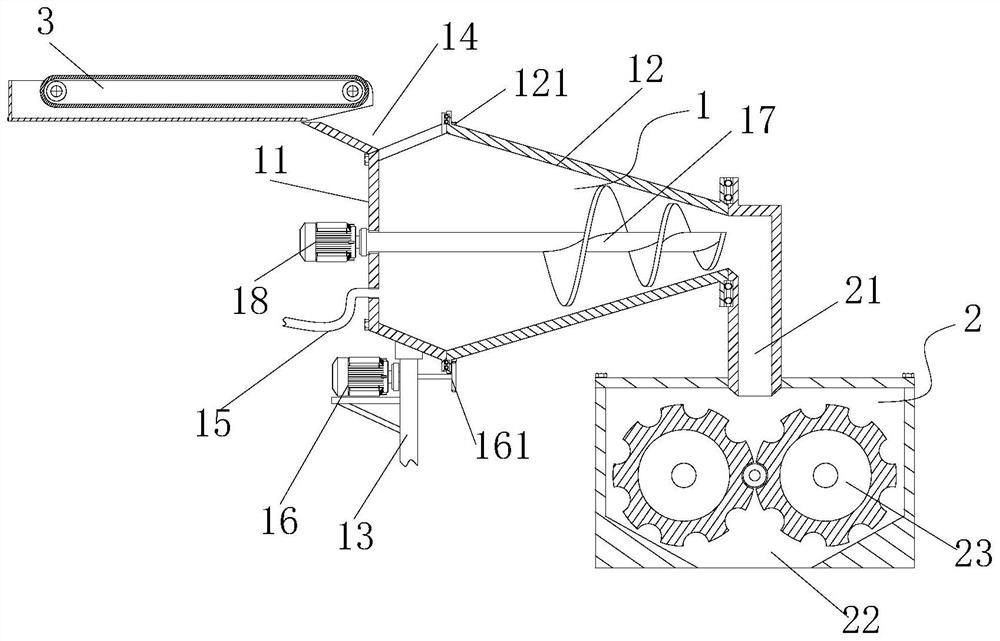

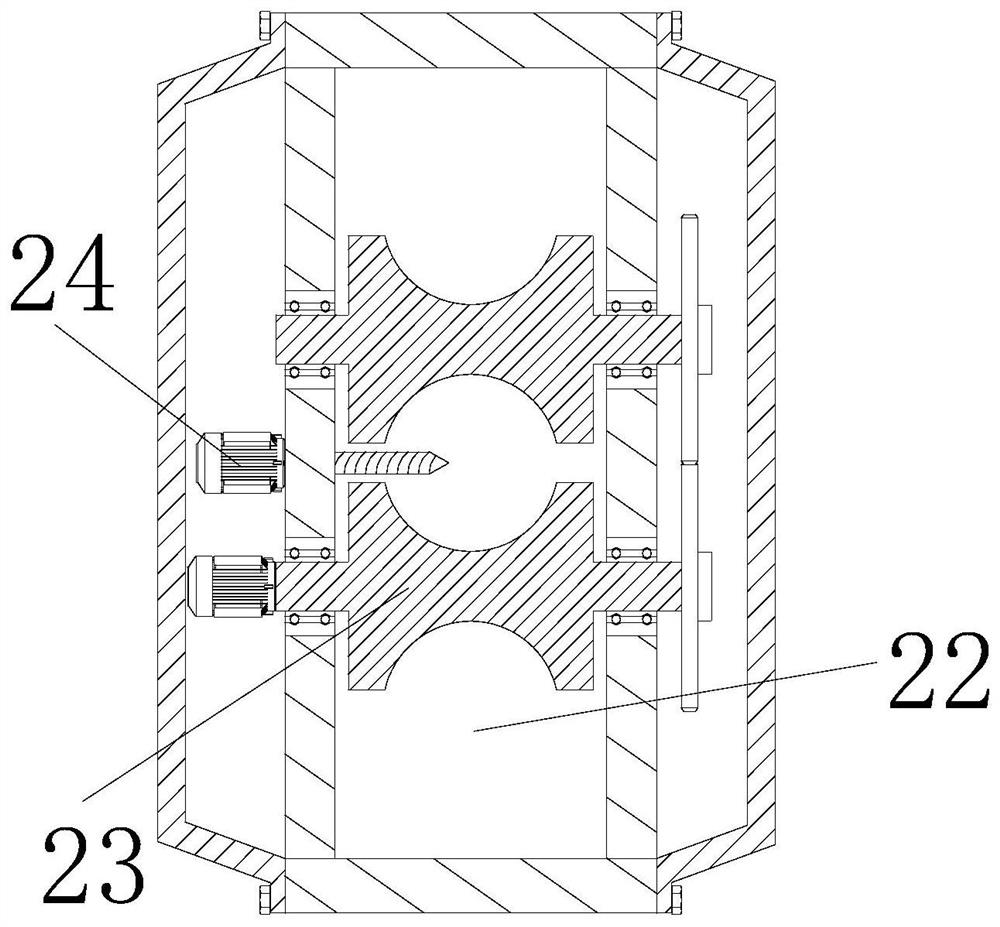

[0028] In order to make the objectives, technical solutions and advantages of the present disclosure more clear, the present disclosure will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present disclosure, but not to limit the present disclosure.

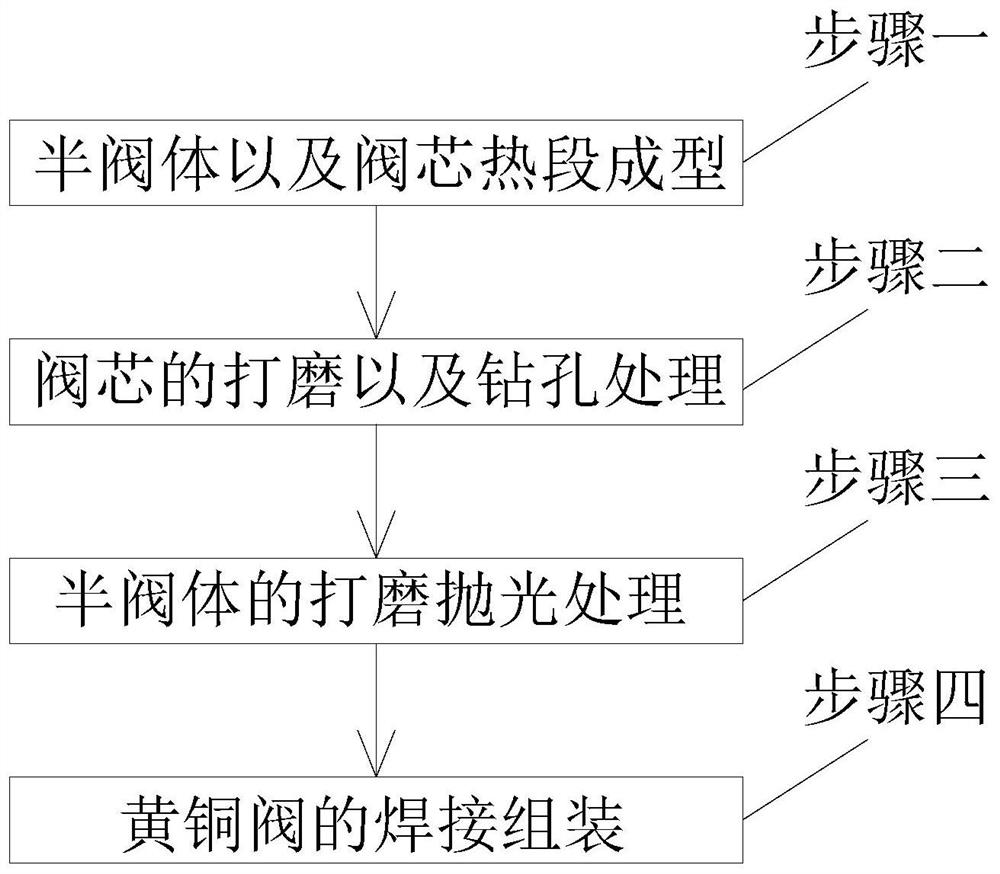

[0029] see Figure 1-3 , the present disclosure provides a technical solution: a brass valve processing method, comprising the following steps:

[0030] Step 1: Die-casting the half valve body and valve core;

[0031] Step 2: Grinding and drilling of the valve core;

[0032] Step 3: Grinding and polishing of the half valve body;

[0033] Step 4: Welding and assembly of brass valve;

[0034] The grinding of the valve core is performed by the drum sand polishing machine 1, and the ground spherical valve cores are introduced into the drilling equipment 2 one by one to be clamped an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com