Waste plastic classified recycling device and method

A waste plastic and recycling device technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems that metal materials cannot be reasonably sorted and recycled, metal resource waste, etc., so as to reduce the manual cleaning process, avoid waste, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

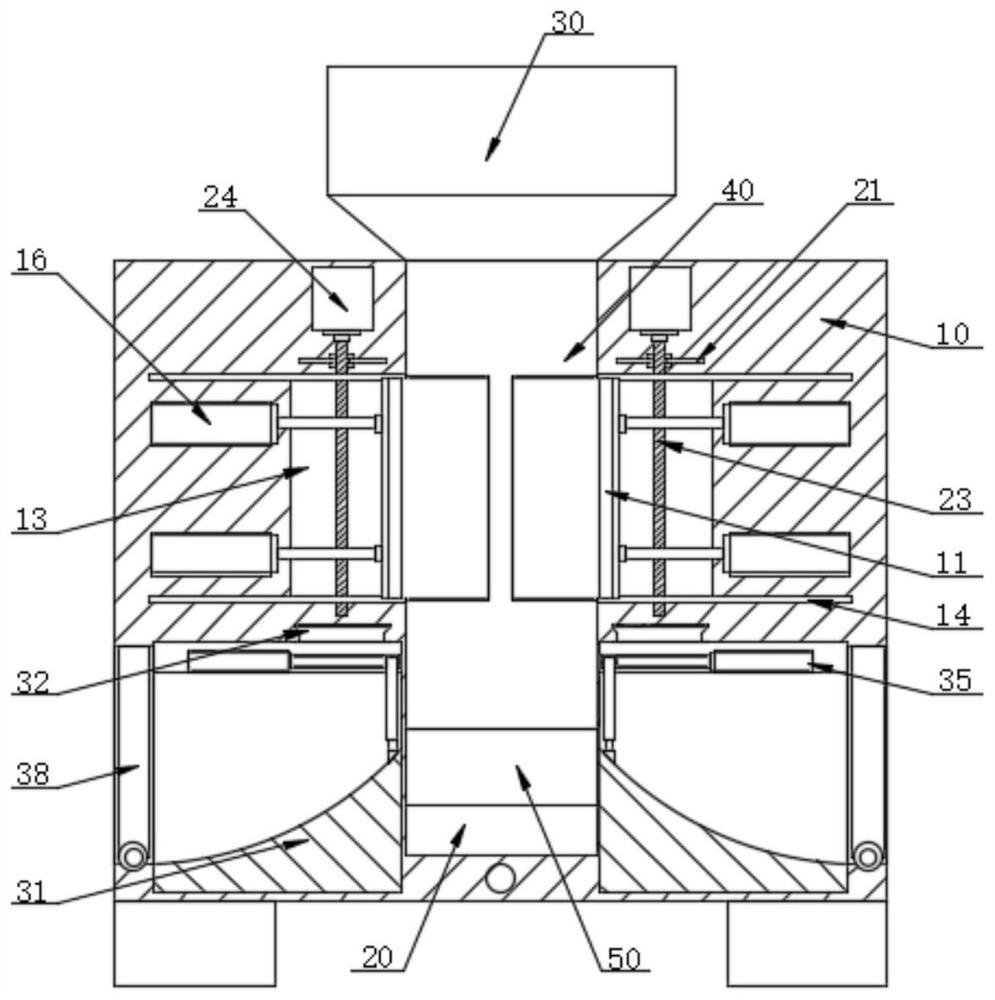

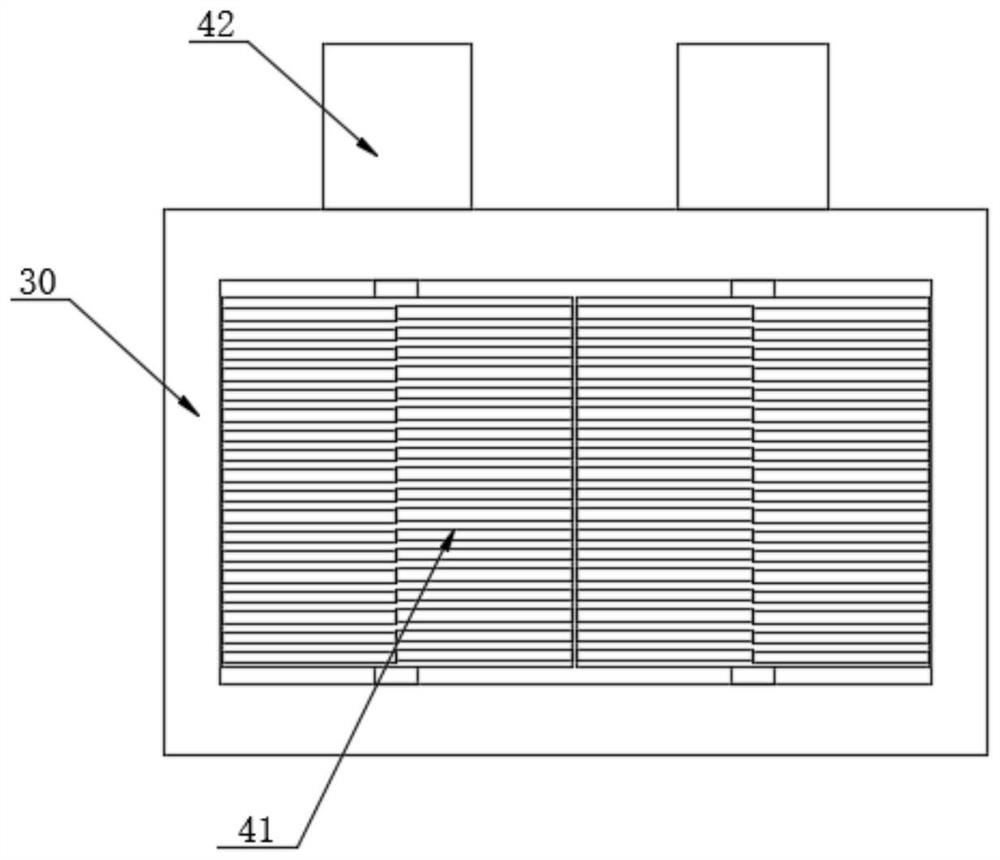

[0033] see figure 1 As shown, a sorting and recycling device for waste and old plastics includes a recycling box 10 and a feeding frame 20, the feeding frame 20 is located on the front of the recycling box 10, and the rear end of the feeding frame 20 extends to the inside of the recycling box 10, and the recycling box The top of 10 is provided with feeding hopper 30, and the bottom end of feeding hopper 30 is provided with feed pipe 40, and the bottom of recovery box 10 inside is provided with drying box 50, and feeding frame 20 is positioned at the inside of drying box 50, guides The bottom of the material pipe 40 runs through the drying box 50 and extends to the top of the feeding rack 20. The bottom of the drying box 50 is provided with several water-permeable holes, and the bottom of the recovery box 10 is provided with a drainage pipe. The crushed material is sent out, and the water in the crushed material is collected through the permeable hole at the bottom of the dryin...

Embodiment 2

[0035] see figure 1 , Figure 4 with Figure 5As shown, both sides of the interior of the recovery box 10 are provided with a recovery mechanism, and the recovery mechanism includes two recovery racks 11, and the inside of the two recovery racks 11 is equipped with an electromagnet, and the switch of the electromagnet inside the two recovery racks 11 is opened. When the metal material in the crushed material passes through the interior of the recovery rack 11, the metal material is adsorbed on the surface of the recovery rack 11, and the unadsorbed material falls into the inside of the drying box 50 through the feed pipe 40, and the two recovery racks 11 are located Both sides of the inside of the feed pipe 40 are arranged symmetrically, and both sides of the inside of the feed pipe 40 are provided with through holes that match the recovery frame 11. The inside of the feed pipe 40 is provided with a distribution rack 12, and the crushed material Enter the inside of the feed ...

Embodiment 3

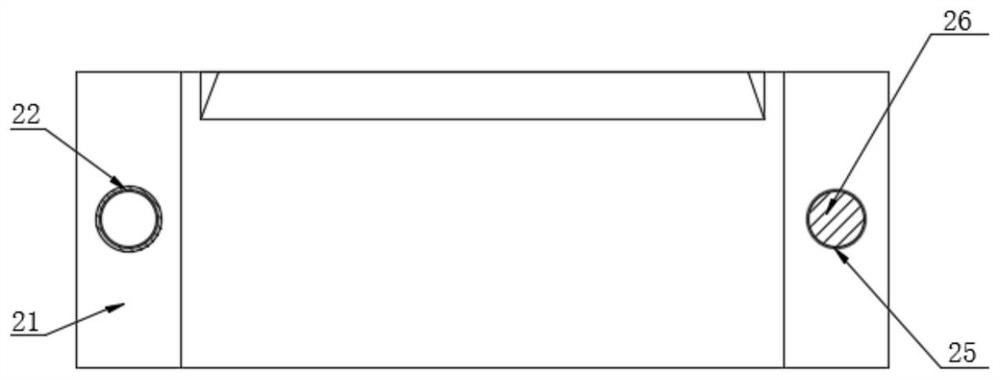

[0037] see figure 1 with image 3 As shown, both sides of the recovery box 10 are provided with a scraper mechanism, the scraper mechanism includes a scraper 21, the rear side of the scraper 21 is provided with a threaded hole 22, and the inner thread of the threaded hole 22 is connected with a screw 23. Both sides of the recovery box 10 are provided with servo motors 24, and one end of the drive shaft of the two servo motors 24 is fixedly connected to the top of the two screw rods 23 through a coupling, and the bottom end of the screw rod 23 is connected to the recovery box 10. The internal rotation connection of the scraper plate 21 is provided with a slide hole 25 inside the front side, and the inside of the slide hole 25 is provided with a slide bar 26. The output shaft drives the screw rod 23 to rotate, and the surface of the screw rod 23 cooperates with the internal thread of the threaded hole 22. At the same time, the front sliding hole 25 of the scraper plate 21 slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com