Special production equipment for special-shaped commutator and production process of special-shaped commutator

A technology for production equipment and commutators, which is applied in special-shaped commutator production equipment and its production process, and can solve problems such as low production efficiency, large consumption, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

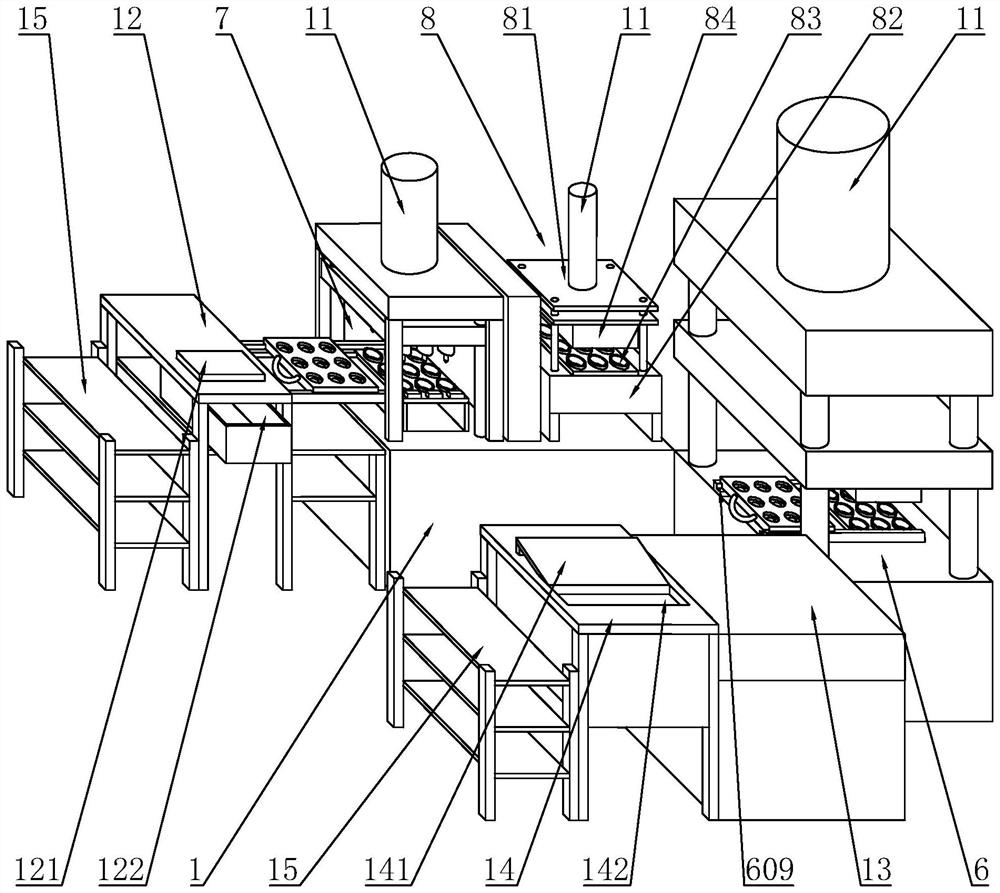

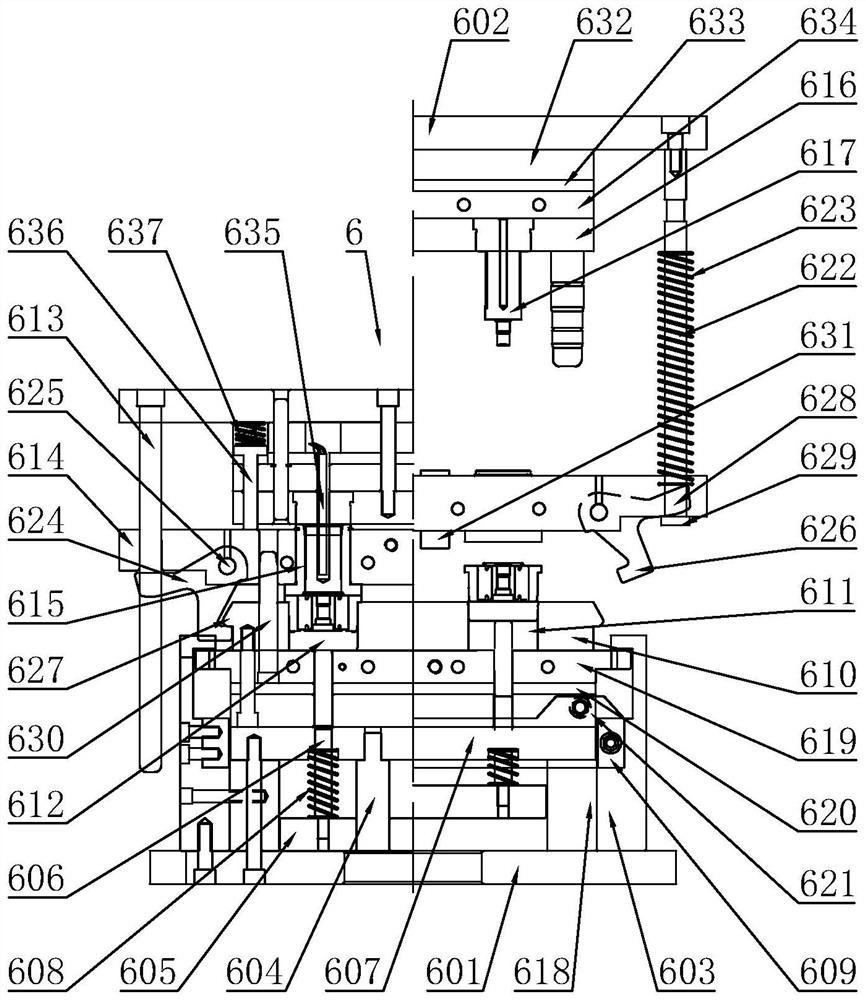

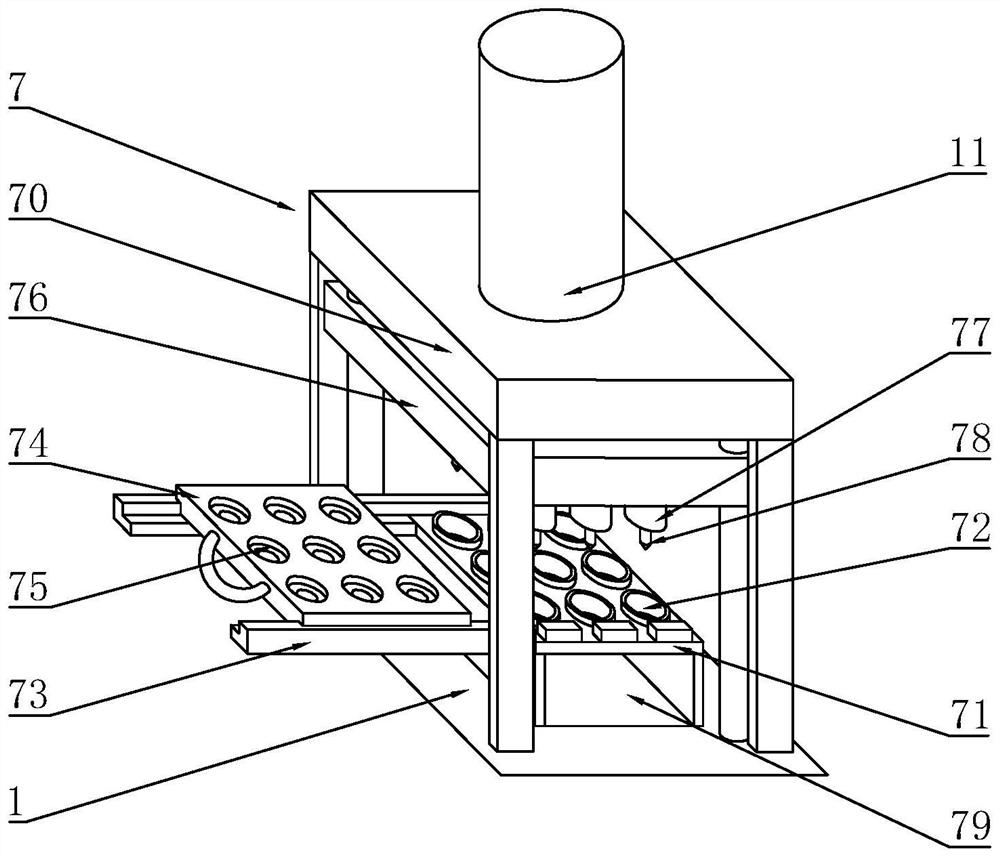

[0036] Such as Figure 1 to Figure 8 The special-shaped commutator production equipment shown includes a workbench 1, a guide plate 2, a positioning ring 3 for positioning the commutator segment group 9, a tight ring bush 4 for fixing the commutator segment group 9, Product forks 5 and drive cylinders 11 for clamping ring bushings 4 in batches, the workbench 1 is arranged in a semi-enclosed shape, and an injection molding station 6 is arranged in the middle of the workbench 1. The left side is provided with an inspection platform 12, a mold sending station 7, and a preheating station 8 in turn, and the right side of the workbench 1 is provided with a cake heating device 13 and a burr treatment station 14. The outer sides of the inspection table 12 and the burr treatment station 14 are provided with a placement frame 15 for placing the commutator segment group 9 and the finished commutator; the commutator segment group 9 to be processed includes a commutator segment body 91, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com