Sterilization equipment for food safety production

A technology of food safety and sterilization equipment, which is applied in the direction of packaging sterilization, etc., can solve the problems of low inactivation efficiency, insufficient continuous operation of sterilization, and impact on quality, so as to improve the effect of grainy food anti-mixing operation and ensure pretreatment Perfection and the effect of guaranteeing completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

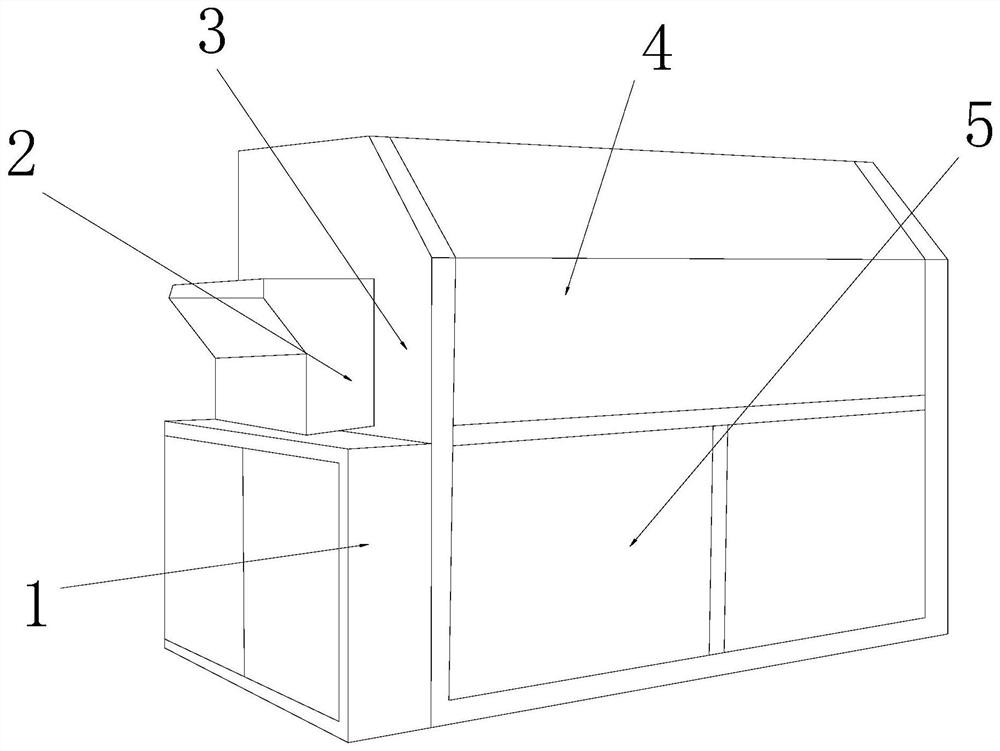

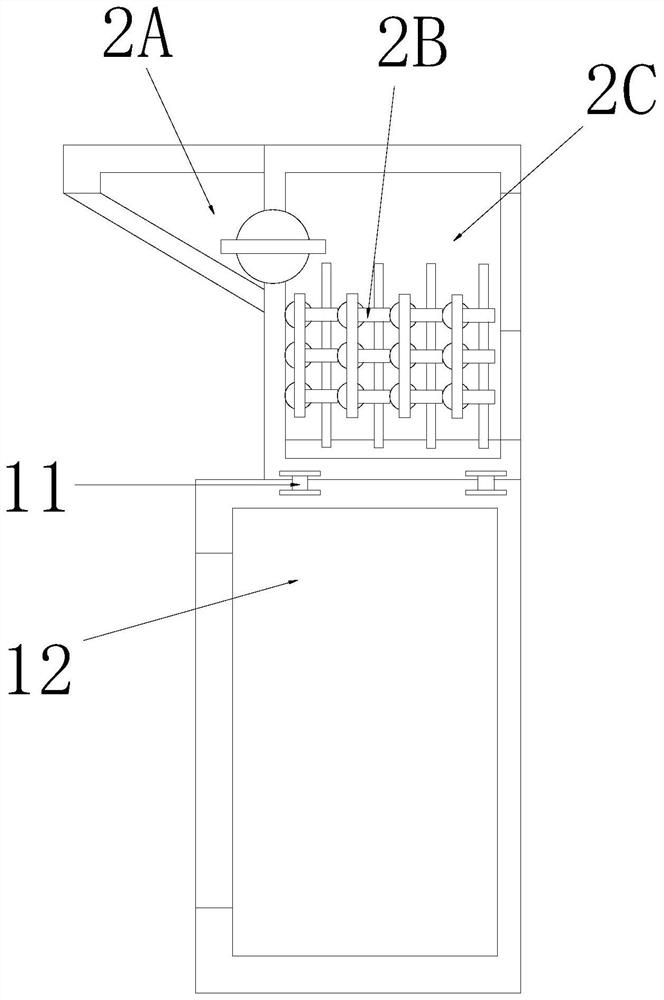

[0035] see Figure 1-Figure 8 , the present invention provides a kind of sterilization equipment for food safety production, its structure comprises: side position cabinet body 1, feeding grid tube groove 2, sterilization horizontal tank cabinet 3, end cover flap 4, front end coaming plate 5, described The feeding grid cylinder groove 2 is inserted and embedded on the top of the side cabinet body 1 and is on the same vertical plane, and the side cabinet body 1 and the feeding grid cylinder groove 2 are both closely attached to the sterilization horizontal tank cabinet 3 On the left side of the left side, the end cover flap 4 is mechanically connected to the sterilizing tank cabinet 3 through hinges, and the front end panels 5 are provided with two and are all attached to the front side of the sterilizing tank cabinet 3. The material grid cylinder groove 2 is provided with a wheel plate frame notch 2A, a grid plate rod frame 2B, and a feed cylinder groove 2C. On the vertical p...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a kind of sterilizing equipment for food safety production, other aspects are the same as embodiment 1, the difference is:

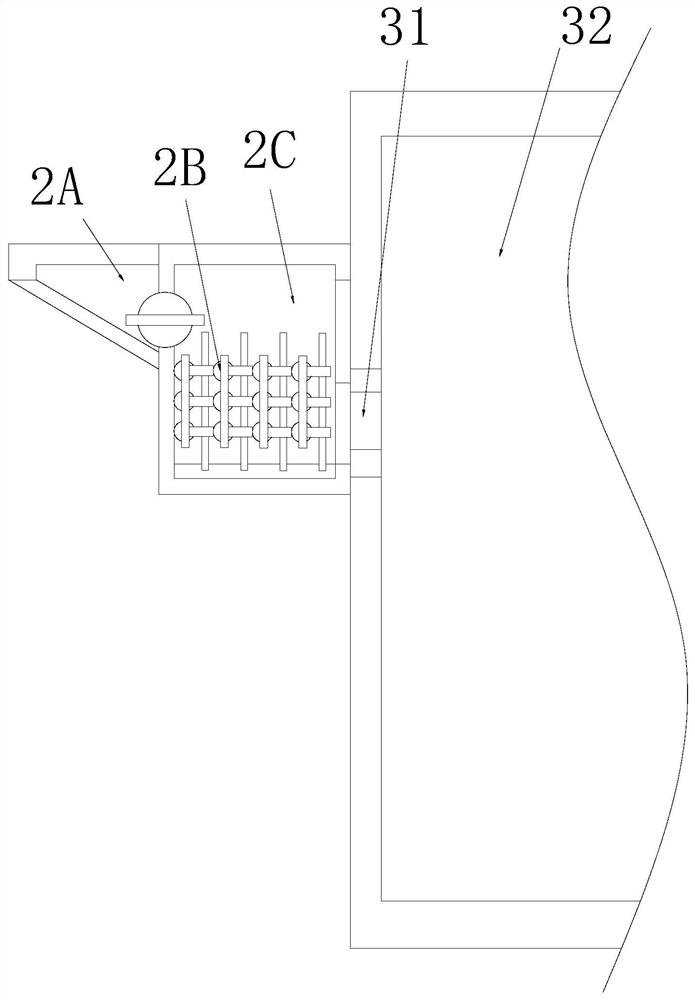

[0044] see image 3 , the sterilizing sleeping tank cabinet 3 is made up of an opening ring 31 and a sleeping cabinet tank body 32, the opening ring 31 is installed on the left side of the sleeping cabinet tank body 32, the opening ring 31 and the sleeping cabinet tank body 32 It has an integral structure and communicates with each other. Through the opening ring 31, the opening on the left side of the cabinet tank 32 forms the operation effect of receiving and communicating with the sieving.

[0045] see Figure 6 , the port ring 31 is composed of a collar frame 311 and a corrugated inner ring 312, the corrugated inner ring 312 is installed inside the collar frame 311, the collar frame 311 and the corrugated inner ring 312 are nested into one and The axes are collinear, and the corrugated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com