Intelligent dispatching system and method for green tire conveying

A technology of intelligent dispatching and green embryos, which is applied in the field of intelligent dispatching system for embryo transportation, can solve the problems of unable to realize centralized scheduling of embryo transportation, unable to maintain and change storage rules, high configuration and low efficiency, etc., to extend the storage period of embryos, The effect of improving utilization rate and conveying efficiency and reducing molding stoppage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

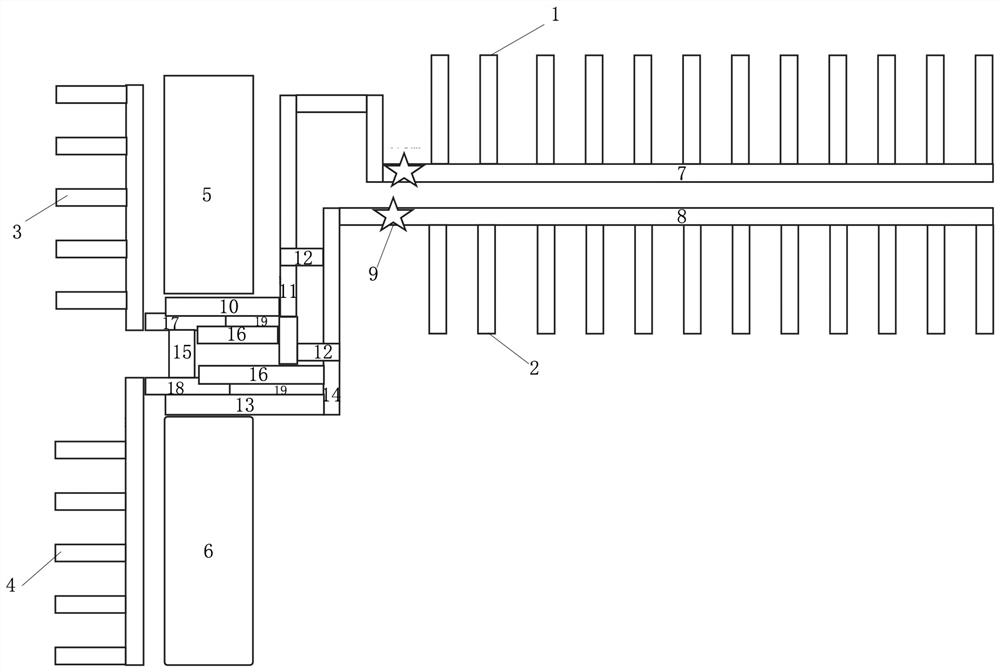

[0053] Embodiment 1 - an intelligent scheduling system for embryo transportation

[0054] Such as figure 1 As shown, an intelligent scheduling system for tire embryo transportation includes:

[0055] Forming unit: including line B forming unit 2 and line C forming unit 1;

[0056] Vulcanizing unit: including vulcanizing unit 3 in the south area and vulcanizing unit 4 in the north area;

[0057] Stereoscopic warehouse: Warehouse A 6 in the three-dimensional warehouse storage area in the north area and warehouse B 5 in the three-dimensional warehouse storage area in the south district; the three-dimensional warehouses are equipped with a storage platform and a storage entrance, and a storage platform and a warehouse exit, respectively. Platform 13, storage entrance 14 of warehouse A, storage platform 10 of warehouse B and storage entrance 11 of warehouse B;

[0058] Main line for storage and main line for storage: main line B for storage and line C for main line 7 for storage, ...

Embodiment 2

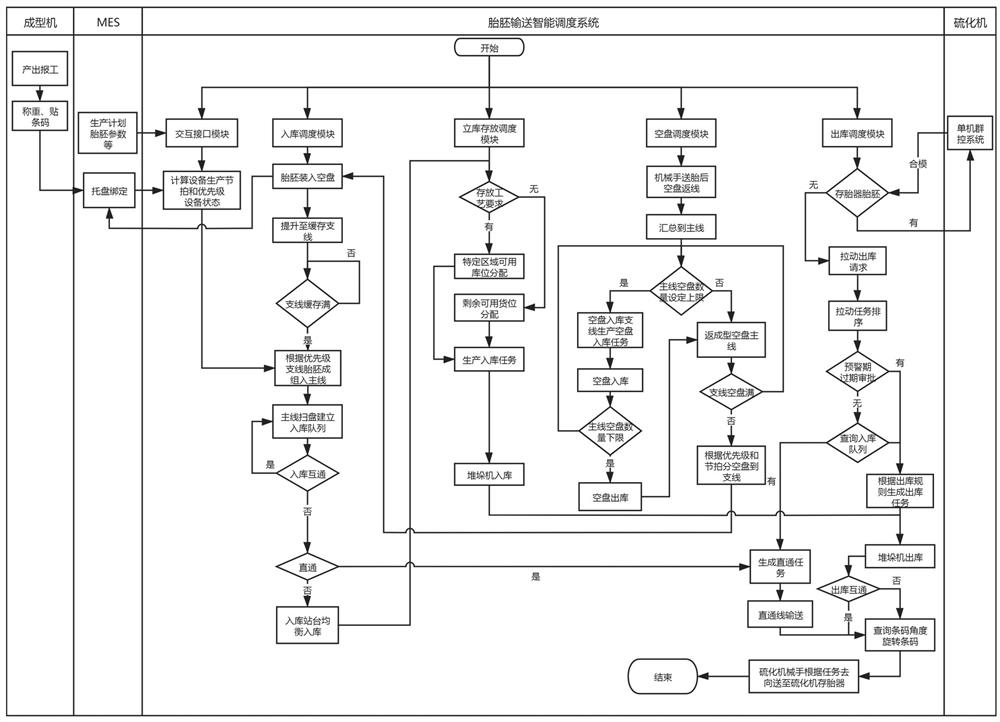

[0062] An intelligent scheduling method for embryo transportation, which uses the above intelligent scheduling system for embryo transportation, and also includes an interactive interface module, a warehouse-in scheduling module, a three-dimensional inventory scheduling module, and a warehouse-out scheduling module, and the interactive interface module interacts with the MES data of the manufacturing execution system ; The specific scheduling process is:

[0063] (1) Arranging the priority of production equipment through the interactive interface module

[0064] The interactive interface module obtains the production status of the molding unit in the current system from the manufacturing execution system MES, and then calculates the output beat, and obtains the output beat order;

[0065] According to the distance of each molding machine from the storage port, the output beat sequence is fine-tuned to obtain the priority of the molding machine in the final molding unit;

[00...

Embodiment 3

[0078] It also includes an empty tray scheduling module; after the embryos are sent to the vulcanizer, the empty trays merge to the empty tray return line 19, and the number of empty trays on the empty tray return line 19 determines whether the empty trays are stored and whether they need to be shipped out; the empty tray return line 19 Intelligently allocate empty trays to corresponding molding machines according to the priority of the molding machine and the output beat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com