Solvent-free polyurethane capable of absorbing grains and preparation method thereof

A technology of solvent-free polyurethane and polyester polyol, which is applied in textiles and papermaking, can solve the problems of increasing the energy consumption of embossing and increasing the difficulty of embossing of solvent-free polyurethane, and achieves low viscosity flow temperature, excellent embossing effect and Mechanical properties, feel full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

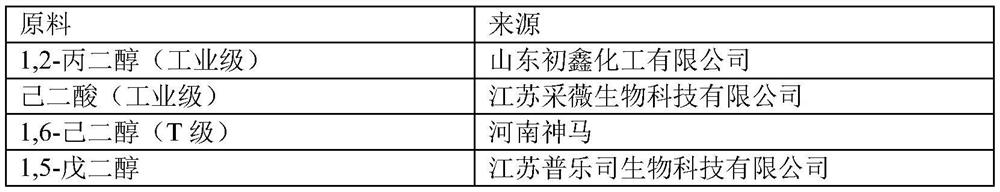

[0040] The preparation method of polyester polyol is as follows: fully react 408g of 1,2-propanediol and 615g of adipic acid at a temperature of 220°C, after dehydration treatment, vacuum treatment under the condition of vacuum degree of 0.1Mpa , to prepare a polyester polyol with a molecular weight of 1000 g / mol.

preparation example 2

[0042] The preparation method of polyester polyol is as follows: fully react 408g of 1,2-propanediol and 615g of adipic acid at a temperature of 220°C, after dehydration treatment, first vacuumize under the condition of vacuum degree of 0.06Mpa , and then vacuumized under the condition of a vacuum degree of 0.1Mpa to prepare a polyester polyol with a molecular weight of 1000g / mol.

Embodiment 1

[0045] A preparation method for absorbable texture-free solvent-free polyurethane, comprising the following steps:

[0046] S1, prepare component A, component B and component C respectively;

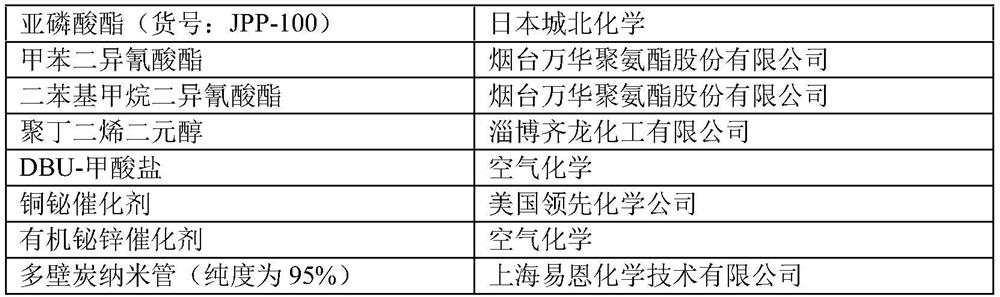

[0047] The preparation method of component A is as follows: at 55°C, put 1,6-hexanediol, 1,5-pentanediol, phosphite and the polyester polyol prepared in Preparation Example 1 in the reaction kettle After mixing and stirring at a speed of 143 rpm for 1 hour, component A was prepared, and the specific dosage is shown in Table 2;

[0048] The preparation method of component B is as follows: at 75°C, add polybutadiene diol to a reaction kettle containing toluene diisocyanate and diphenylmethane diisocyanate, and react for 2 hours to obtain an NCO content of 12.9%. Component B, the specific dosage is shown in Table 2;

[0049] Wherein the preparation method of component C is as follows: DBU-formate and copper-bismuth catalyst are mixed and stirred uniformly in the reactor at 140 rpm to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com