Preparation method of ecological tea oil

A camellia oil, ecological technology, applied in the direction of oil/fat refining, fat production, edible oil/fat, etc., can solve the problems of high smoke point, insufficient purity of camellia oil, weak health care effect, etc., to reduce peroxides. Produces, reduces the production of toxins, reduces the effect of invasive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

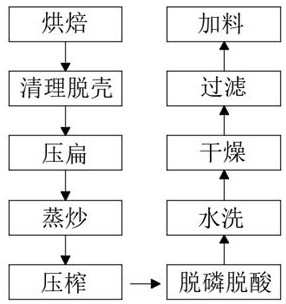

Image

Examples

Embodiment 1

[0028] 1) Baking: Dry the picked camellia seeds in the sun, wait until the shell and pulp are separated, and then put them on the steaming bed to dry the residual moisture in the tea seeds. The drying temperature is 45°C. During the baking process, the tea seeds are baked until the moisture content is 10%;

[0029] 2) Cleaning and dehulling: After the roasting is completed, the impurities and mildewed tea seeds in the tea seeds are removed by air selection, screening and magnetic separation, and then the tea seeds are cleaned by shelling machines, fans and tea husk separators. Carry out shelling treatment;

[0030] 3) Flattening: the tea kernels separated from the seed shells are flattened by a flattening machine, and the thickness of the tea kernels is flattened to 0.2cm, so that the flattened tea kernels are cracked;

[0031] 4) Steaming and frying: steaming and frying in a wok to make the tea kernels leak oily light, the steaming temperature is 100°C, during the steaming a...

Embodiment 2

[0039] 1) Baking: Dry the picked camellia seeds in the sun, wait for the shell and pulp to separate, and then put them on the steaming bed to dry the residual moisture in the tea seeds. The drying temperature is 50°C. During the baking process, the tea seeds are baked Until the moisture content is 13%;

[0040] 2) Cleaning and dehulling: After the roasting is completed, the impurities and mildewed tea seeds in the tea seeds are removed by air selection, screening and magnetic separation, and then the tea seeds are cleaned by shelling machines, fans and tea husk separators. Carry out shelling treatment;

[0041] 3) Flattening: the tea kernels separated from the seed shells are flattened by a flattening machine, and the thickness of the tea kernels is flattened to 0.2-0.4cm, so that the flattened tea kernels are cracked;

[0042] 4) Steaming and frying: steaming and frying in a wok to make the tea kernels leak oily light. The steaming temperature is 110°C. During the steaming a...

Embodiment 3

[0050] 1) Baking: Dry the picked camellia seeds in the sun, wait until the shell and pulp are separated, and then put them on the steaming bed to dry the residual moisture in the tea seeds. The drying temperature is 55°C. During the baking process, the tea seeds are baked Until the moisture content is 15%;

[0051] 2) Cleaning and dehulling: After the roasting is completed, the impurities and mildewed tea seeds in the tea seeds are removed by air selection, screening and magnetic separation, and then the tea seeds are cleaned by shelling machines, fans and tea husk separators. Carry out shelling treatment;

[0052] 3) Flattening: the tea kernels separated from the seed shells are flattened by a flattening machine, and the thickness of the tea kernels is flattened to 0.4cm, so that the flattened tea kernels are cracked;

[0053] 4) Steaming and frying: steaming and frying in a wok to make the tea kernels leak oily light, the steaming temperature is 120°C, during the steaming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com