Preparation method of non-woven fabric capable of releasing faint scent permanently

A non-woven fabric and fragrance-free technology, which is applied in the processing of textile materials, equipment configuration, textiles and papermaking, and textile materials processing. It can solve problems such as not being able to be dried well, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

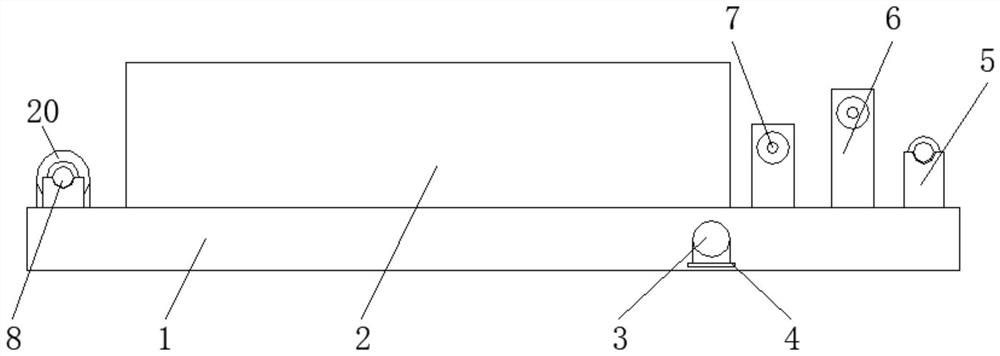

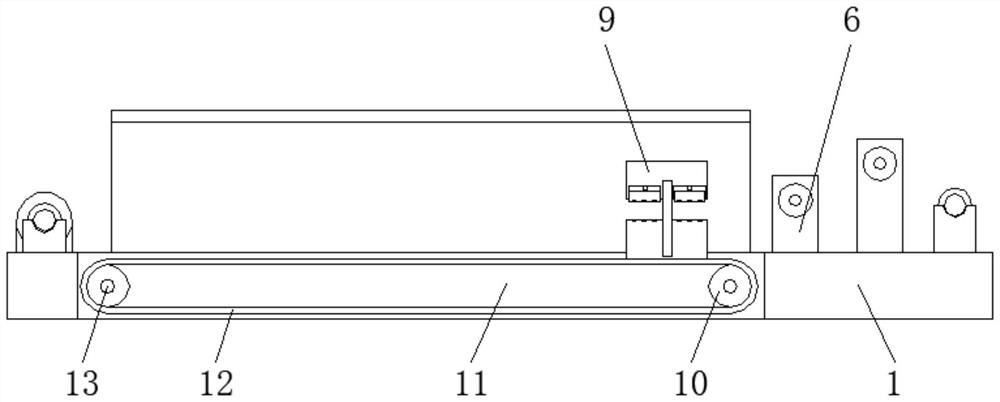

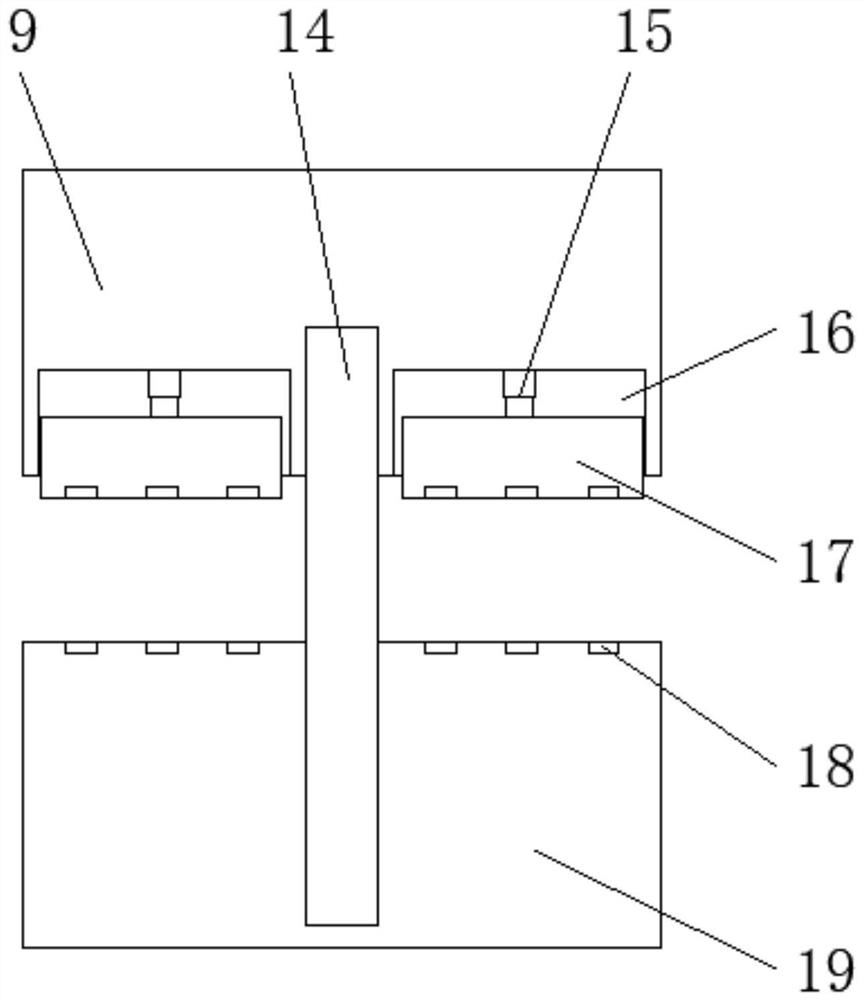

Image

Examples

Embodiment 1

[0028] A kind of non-woven fabric preparation method that releases delicate fragrance for a long time, carries out through the following steps:

[0029] 1) Take the raw materials needed to prepare the fragrance liquid, and stir the raw materials evenly;

[0030] 2) placing the prepared non-woven fabric in the fragrance liquid for standing;

[0031] 3) Ultrasonic treatment is carried out to the non-woven fabric entering the fragrance liquid;

[0032] 4) cleaning the treated non-woven fabric;

[0033] 5) Place the cleaned non-woven fabric in a dryer for drying.

[0034] The fragrance liquid in step 1) includes the raw materials of the following main components: plant essential oil, plant antibacterial agent and wax, 20 parts of plant essential oil, plant essential oil is rose essential oil, 1 part of plant antibacterial agent, 0.5 part of wax, standing time It is 2h, the ultrasonic treatment time is 30min, and the drying temperature of the dryer is 25°C.

Embodiment 2

[0036] A kind of non-woven fabric preparation method that releases delicate fragrance for a long time, carries out through the following steps:

[0037] 1) Take the raw materials needed to prepare the fragrance liquid, and stir the raw materials evenly;

[0038] 2) placing the prepared non-woven fabric in the fragrance liquid for standing;

[0039] 3) Ultrasonic treatment is carried out to the non-woven fabric entering the fragrance liquid;

[0040] 4) cleaning the treated non-woven fabric;

[0041] 5) Place the cleaned non-woven fabric in a dryer for drying.

[0042] The fragrance liquid in step 1) includes the raw materials of the following main components: plant essential oil, plant antibacterial agent and wax, 45 parts of plant essential oil, plant essential oil is lavender essential oil, 2 parts of plant antibacterial agent, 0.65 part of wax, and the standing time is 2h, the ultrasonic treatment time is 30min, and the drying temperature of the dryer is 27.5°C.

[0043...

Embodiment 3

[0045] A kind of non-woven fabric preparation method that releases delicate fragrance for a long time, carries out through the following steps:

[0046] 1) Take the raw materials needed to prepare the fragrance liquid, and stir the raw materials evenly;

[0047] 2) placing the prepared non-woven fabric in the fragrance liquid for standing;

[0048] 3) Ultrasonic treatment is carried out to the non-woven fabric entering the fragrance liquid;

[0049] 4) cleaning the treated non-woven fabric;

[0050] 5) Place the cleaned non-woven fabric in a dryer for drying.

[0051] The fragrance liquid in step 1) comprises the raw materials of the following main components: plant essential oil, plant antibacterial agent and wax, 60 parts of plant essential oil, plant essential oil is osmanthus essential oil, 3 parts of plant antibacterial agent, 0.8 part of wax, and the standing time is 2h, the ultrasonic treatment time is 30min, and the drying temperature of the dryer is 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com