Manufacturing process of green-surface wave-wrinkle-free straight-edge matting curtain and matting curtain

A manufacturing process and technology of curtains, applied in the field of matting curtains, can solve the problems of affecting image quality, wrinkles and ripples, easy to produce curling, etc., and achieve the effect of improving verticality, preventing curling, and maintaining flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

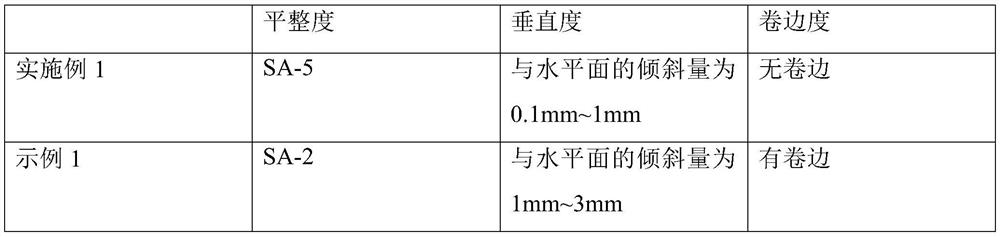

Embodiment 1

[0027] The manufacturing process of a green-surface wrinkle-free straight-edge cut-out screen disclosed in this embodiment includes the following steps,

[0028] S1. Using green knitted fabric, performing calendering treatment on the knitted fabric;

[0029] S2. Using inorganic powder, dyeing the inorganic powder green, mixing the dyed inorganic powder with the first primer evenly;

[0030] S3. Pressing the first primer obtained in S2 into the knitting treated in S1, and drying it;

[0031] S4. Calendering the knitted fabric treated in S3 for the second time;

[0032] S5, pressing the second primer onto the knitted fabric treated in S4, and drying it to prepare a green cut-out screen.

[0033] In this embodiment, the step of calendering includes heat-pressing the knitted fabric with a calender hot roller, and then cooling the knitted fabric, and the temperature of the calender hot roller is 120°C.

[0034] In this embodiment, in the S2, the inorganic powder is silicon powde...

Embodiment 2

[0042] The manufacturing process of a green-surface wrinkle-free straight-edge cut-out screen disclosed in this embodiment includes the following steps,

[0043] S1. Using green knitted fabric, performing calendering treatment on the knitted fabric;

[0044] S2. Using inorganic powder, dyeing the inorganic powder green, mixing the dyed inorganic powder with the first primer evenly;

[0045] S3. Pressing the first primer obtained in S2 into the knitting treated in S1, and drying it;

[0046] S4. Calendering the knitted fabric treated in S3 for the second time;

[0047] S5, pressing the second primer onto the knitted fabric treated in S4, and drying it to prepare a green cut-out screen.

[0048] In this embodiment, the step of calendering includes heat-pressing the knitted fabric with a calender hot roller, and then cooling the knitted fabric, and the temperature of the calender hot roller is 180°C.

[0049] In this embodiment, in the S2, the inorganic powder is silicon powde...

Embodiment 3

[0057] The manufacturing process of a green-surface wrinkle-free straight-edge cut-out screen disclosed in this embodiment includes the following steps,

[0058]S1. Using green knitted fabric, performing calendering treatment on the knitted fabric;

[0059] S2. Using inorganic powder, dyeing the inorganic powder green, mixing the dyed inorganic powder with the first primer evenly;

[0060] S3. Pressing the first primer obtained in S2 into the knitting treated in S1, and drying it;

[0061] S4. Calendering the knitted fabric treated in S3 for the second time;

[0062] S5, pressing the second primer onto the knitted fabric treated in S4, and drying it to prepare a green cut-out screen.

[0063] In this embodiment, the step of calendering includes heat-pressing the knitted fabric with a calender hot roller, and then cooling the knitted fabric. The temperature of the calender hot roller is 130°C.

[0064] In this embodiment, in the S2, the inorganic powder is silicon powder, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com