Fabricated shear wall building structure and construction method thereof

A technology for building structures and shear walls, applied in building components, building structures, buildings, etc., can solve the problems of increasing the difficulty of operation by construction personnel, unfavorable rapid construction, and slow positioning process, so as to improve connection efficiency and reduce Positioning difficulty, reducing the effect of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

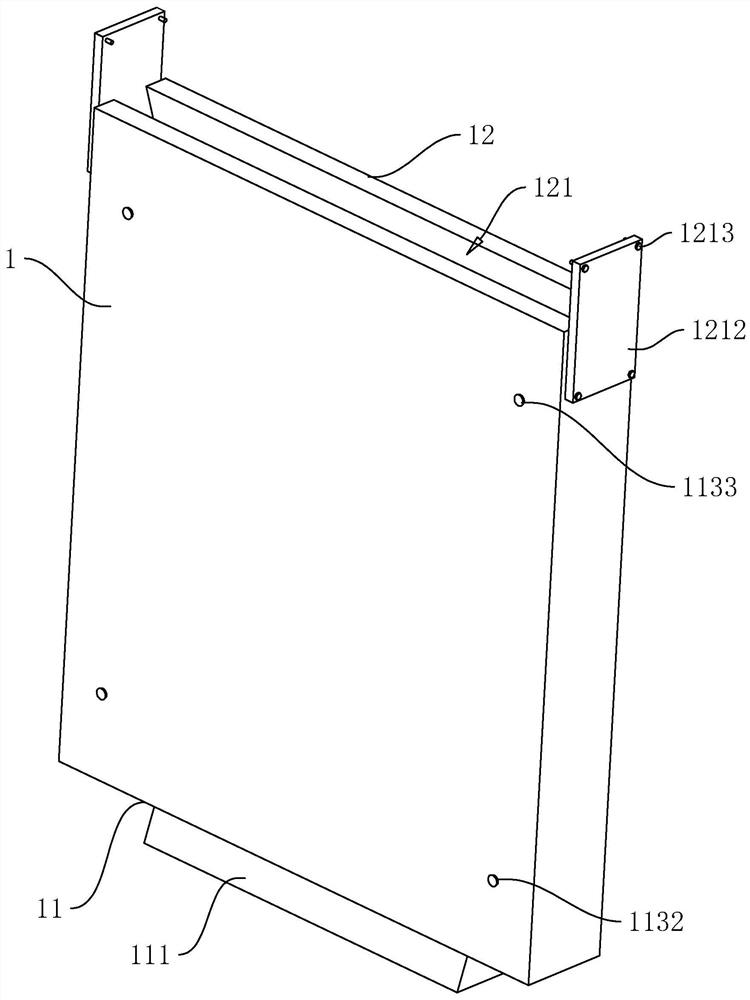

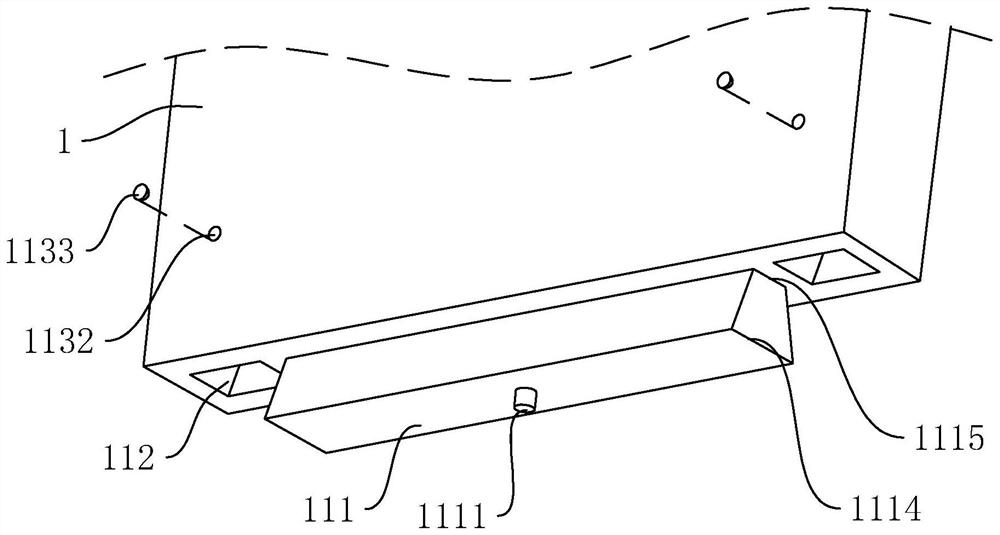

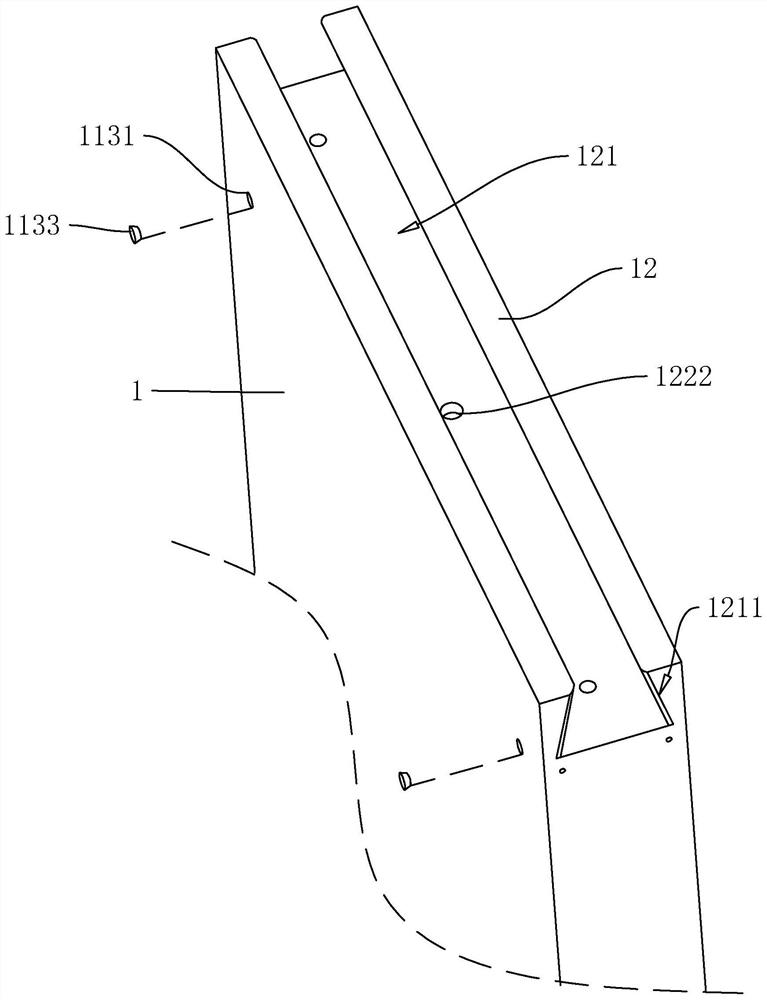

[0044] Present embodiment 1 discloses the prefabricated shear wall building structure, with reference to figure 1 , including an assembly wall 1, the bottom end of the assembly wall 1 is a first connection end 11, and the top end of the assembly wall 1 is a second connection end 12, such as figure 2 As shown, the first connecting end 11 is provided with a slider 111 exposed to the first connecting end 11, as image 3 As shown, the second connecting end 12 is provided with a sliding slot 121 matching with the sliding block 111 . combine figure 2, the first connecting end 11 of the assembly wall 1 is provided with a slurry tank 112, and the slurry tank 112 communicates with the chute 121 of the adjacent assembly wall 1; the tank body formed by the communication between the slurry tank 112 and the chute 121 is Fill tank. Look back figure 1 , the assembly wall 1 is provided with an air outlet 1132 and a pouring hole 1131 for pouring grout.

[0045] The assembled wall body 1...

Embodiment 2

[0058] The construction method of the prefabricated shear wall building structure includes the following steps:

[0059] Lift the assembly wall 1 by a crane, align the slider 111 of the upper assembly wall 1 with the notch 1211 of the lower assembly wall 1, and press the telescopic protrusion 1111 into the receiving groove 1113 of the slider 111 , and then slide the slider 111 of the upper assembly wall 1 into the chute 121 of the lower assembly wall 1 by sliding, and slide to the position where the telescopic protrusion 1111 matches the slot 1222 .

[0060] The sealing plate 1212 is fixed between the first connection end 11 of the upper assembly wall 1 and the second connection end 12 of the lower wall by bolts 1213 .

[0061] Use a grouting machine to inject the slurry into the pouring groove through the pouring hole 1131 . After filling the slurry, use the sealing plug 1133 to plug the air outlet 1132 and the pouring hole 1131 tightly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com