A kind of frp plate anchoring device and anchoring method

A technology of FRP board and anchoring device, which is used in construction, building maintenance, building reinforcements, etc., can solve the problems of FRP board crushing, slippage, inability to effectively anchor FRP wide and thick plates, etc., to avoid sliding out damage, Improve anchoring efficiency and enhance the effect of anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

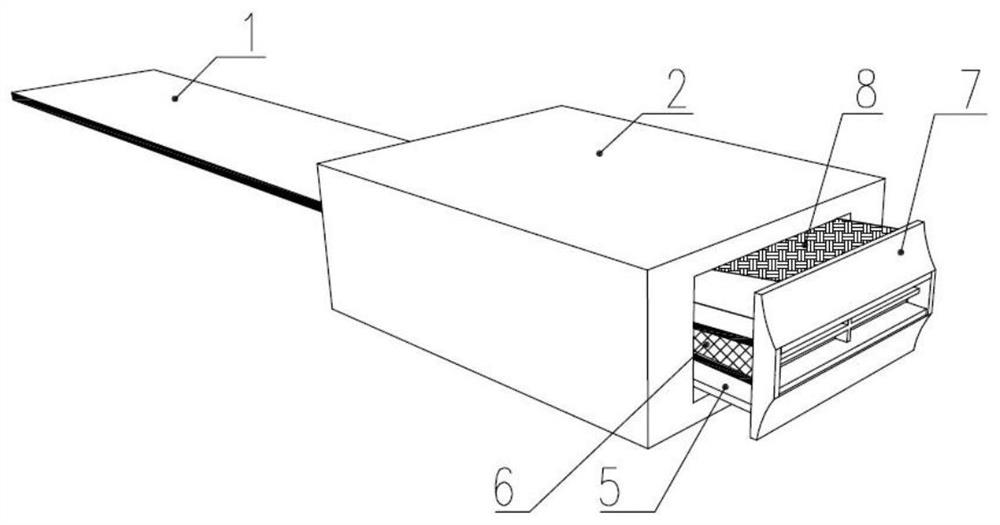

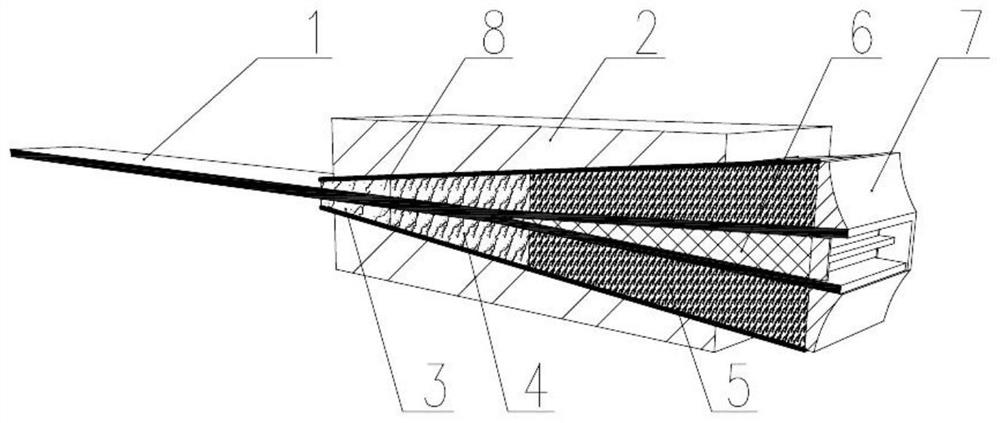

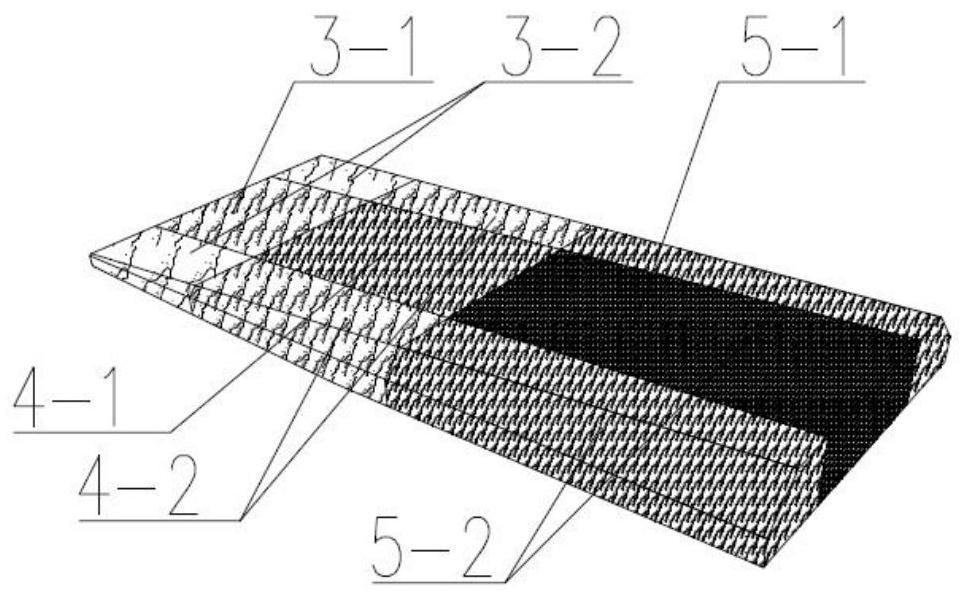

[0065] like figure 1 , figure 2 , Figure 4 shown.

[0066] The steps of the FRP board anchoring method are as follows:

[0067] Cut BFRP with a size of 100 (width) × 5 (thickness) mm into 2 layers from the middle, and the length of the cut is 100 mm;

[0068] Insert the layered BFRP plate into the anchor plate to ensure that the large open end of the anchor plate is closer to the layered part of the BFRP plate;

[0069] Push the wedge-shaped top block made of aluminum alloy into the layered BFRP board and bond with epoxy resin;

[0070] After the resin is completely cured, the upper and lower clips are placed on both sides of the BFRP board whose ends are embedded in the wedge-shaped top block 6 and pushed into the anchor plate together. When pushing in, a jack can be used to push the variable stiffness clip, and the pushing force is the same as the calculated ultimate tensile force of the FRP plate. The finite element simulation results show that the tensile force whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com