Main shaft for scroll compressor and scroll compressor with main shaft

A scroll compressor and spindle technology, applied in the field of scroll compressors, can solve problems such as inability to lubricate and cool, affect the precision of the spindle, and make the process difficult, so as to improve the effect of lubrication and cooling, improve space utilization, and compact The effect of internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

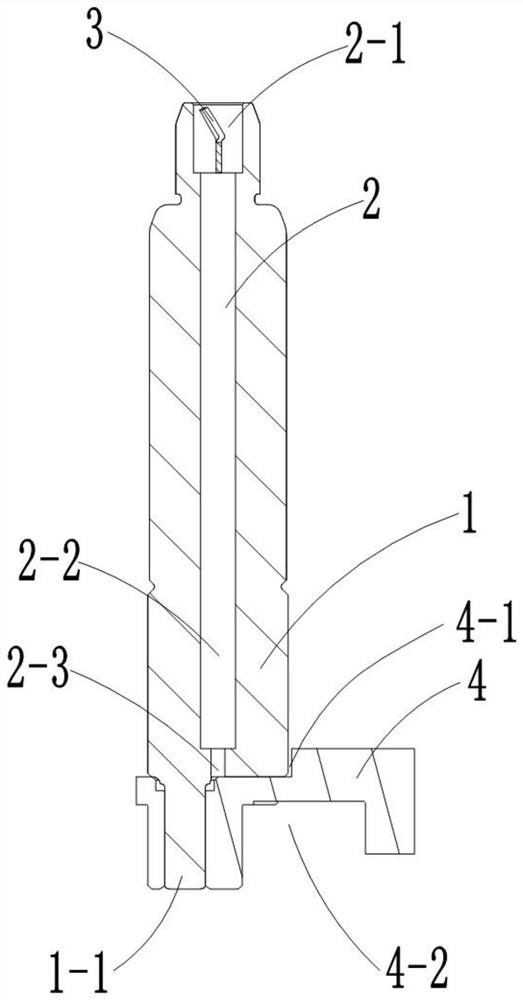

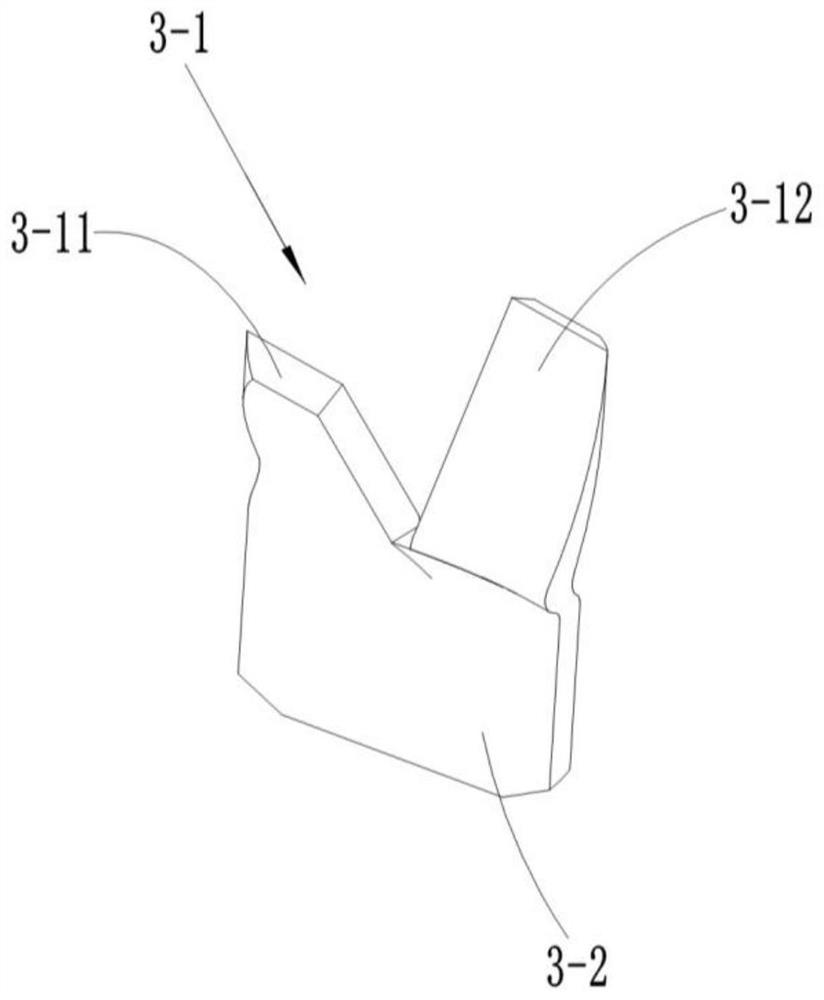

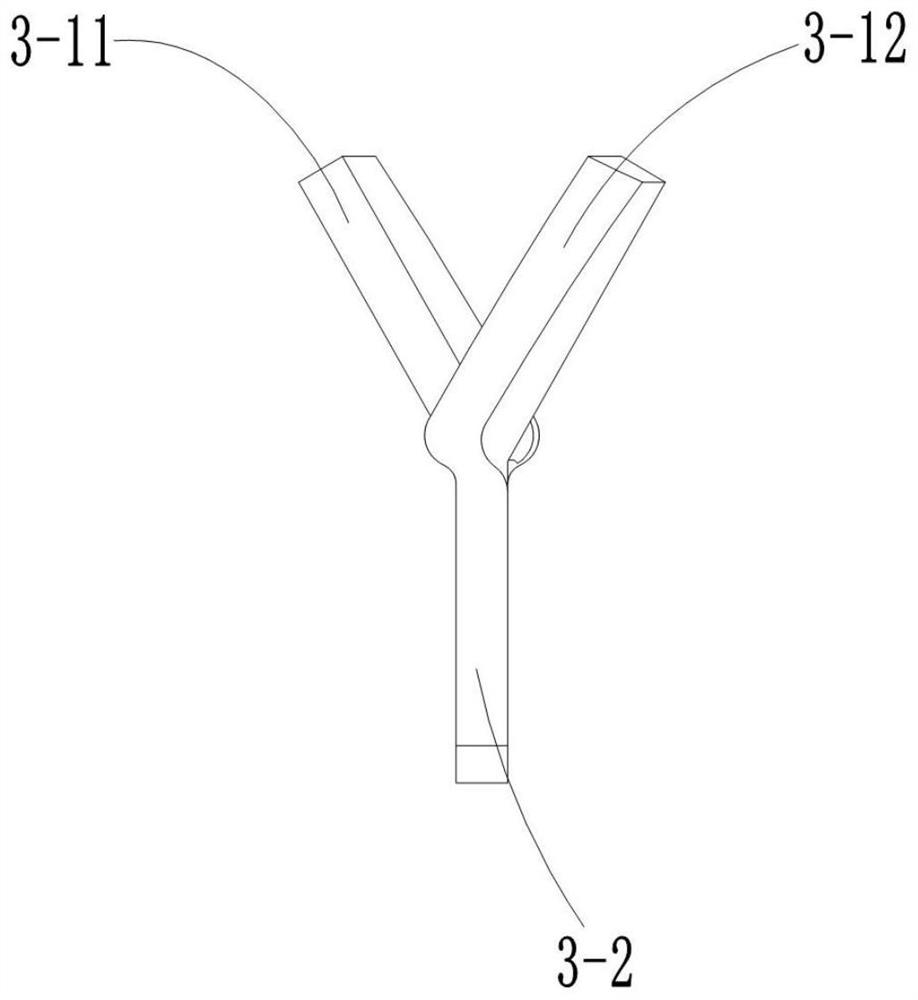

[0035] A main shaft for a scroll compressor, comprising a main shaft body 1, an oil guide channel 2 axially penetrating through the main shaft body 1 is arranged in the main shaft body 1, and the oil guide channel 2 is composed of a first oil guide channel 2-1, a second oil guide channel The channel 2-2 and the third oil guide channel 2-3 are connected in sequence, and the axes of the first oil guide channel 2-1, the second oil guide channel 2-2 and the third oil guide channel 2-3 are aligned with the spindle body The axes of 1 are coincident, the third oil guide channel 2-3 runs through the tail end of the main shaft body 1, the diameter of the first oil guide channel 2-1 is larger than the diameter of the second oil guide channel 2-2, and the second oil guide channel 2- The diameter of 2 is larger than the diameter of the third oil guide channel 2-3, and the rotary vane 3 is clamped in the first oil guide channel 2-1, and the rotary vane 3 is connected by the rotary vane part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com