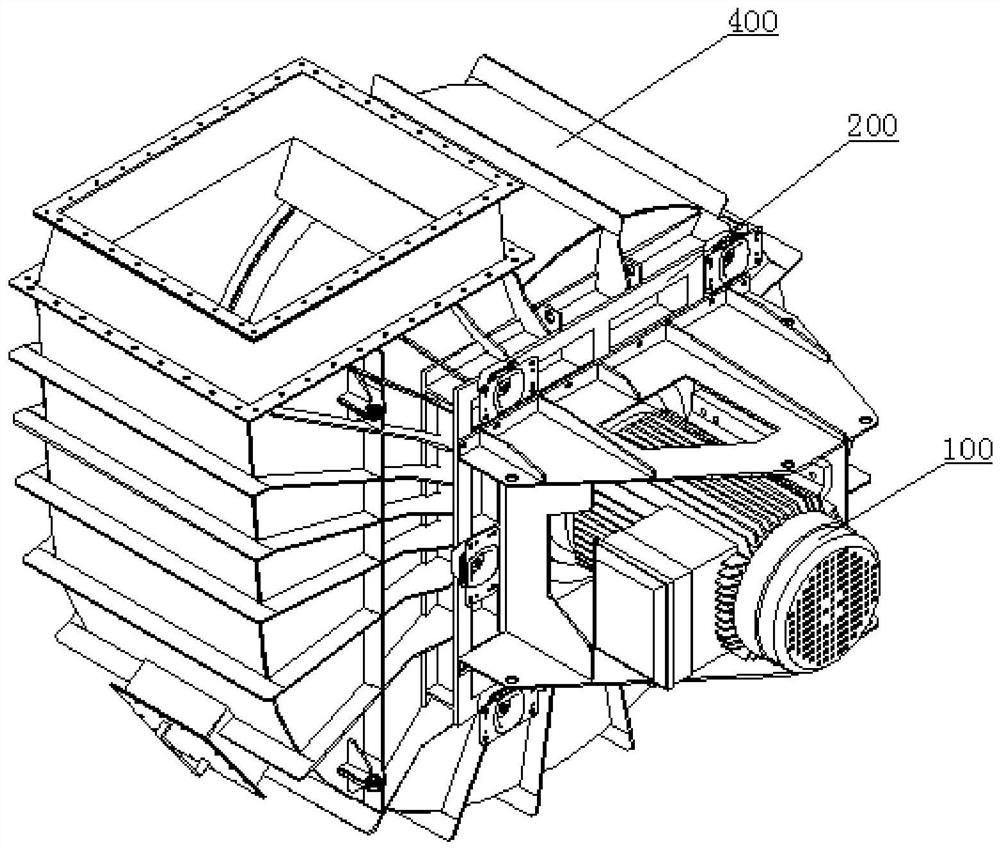

Vertically-mounted drainage shaft seal mechanism and centrifugal fan

A centrifugal fan and shaft seal technology, which is applied in the direction of machines/engines, parts of pumping devices for elastic fluids, pump devices, etc., can solve the problems of damage to carbon ring shaft seals, damage to motors, etc., and achieve protection from corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

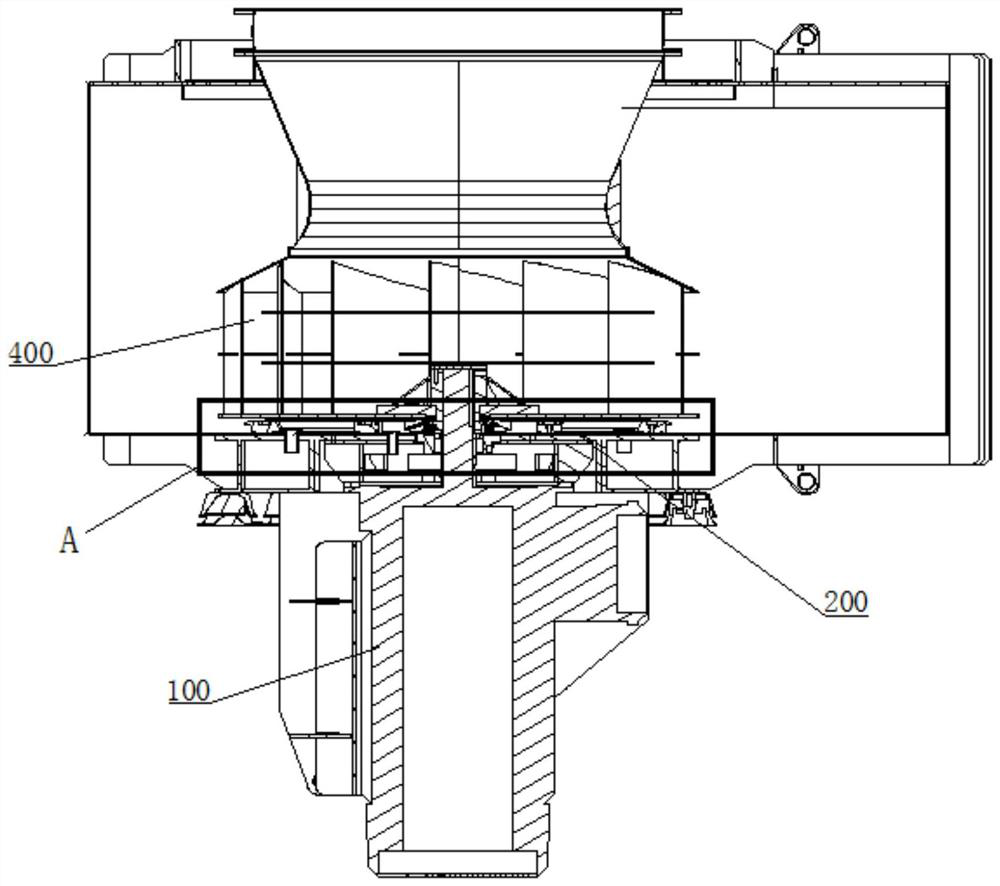

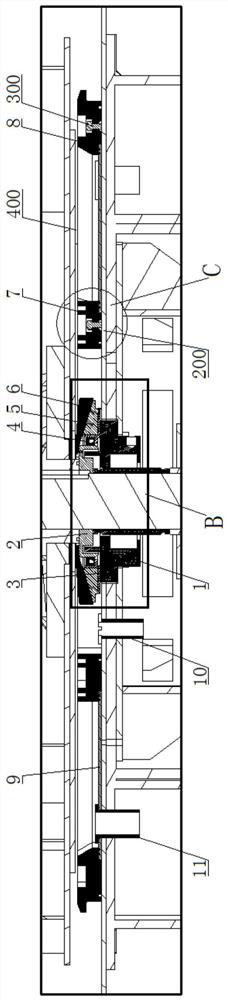

[0022] see Figure 2 to Figure 4 , the present invention provides a vertically installed drainage shaft seal mechanism, including: a shaft seal 1 sleeved on the output shaft of the motor 100, a shaft seal 1 sleeved on the shaft seal 1 and sleeved on the output shaft of the motor 100 Water blocking ring 2, fixed bracket 3 arranged at the outer end of the shaft seal 1, oil seal 4 arranged between the fixed bracket 3 and the water blocking ring 2, sealing bushing arranged at the outer end of the fixed bracket 3 5. And the water throwing ring 6 arranged on the sealing bush 5 . The oil seal 4 is made of stainless steel, the section of the fixing bracket 3 is "L" shape, and the sealing bush 5 is fixed on the fixing bracket 3 by screws. The outer end of the water throwing ring 6 is arranged on the sealing bush 5, and the inner end of the water thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com