Method for measuring carbonization depth of concrete test piece

A technology for concrete specimens and carbonation depth, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of decreased measurement accuracy and inability to measure carbonation depth, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

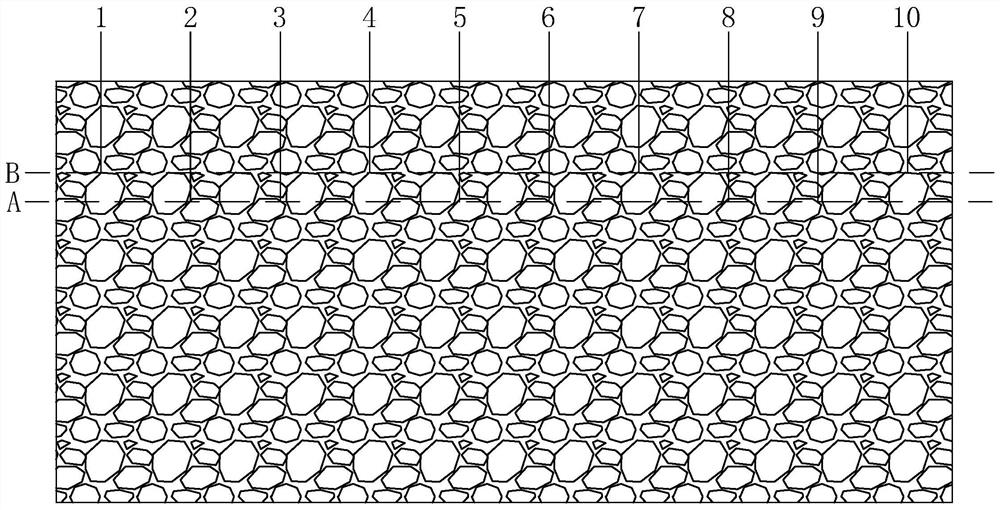

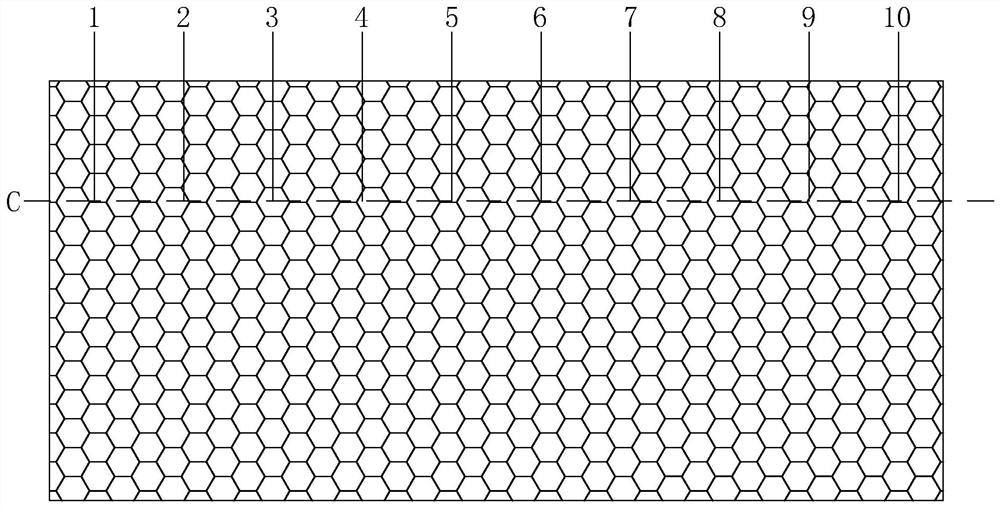

[0026] A method for measuring the depth of carbonation of a concrete test piece, comprising the following steps:

[0027] S1. Making concrete specimens: Weigh the raw materials according to the ratio of the raw material formula, mix and stir the raw materials to obtain concrete, then sieve the concrete through a sieve with a sieve hole of 9.5mm, discard the sieve, and the sieved The particle size of the aggregate left in the concrete is 0-9.5mm, and then the sieved concrete is added to the standard test mold, and the concrete specimen of 100mm×100mm×100mm is made after waiting for the concrete to harden. The raw material formulation ratio of the concrete specimens is shown in Table 1.

[0028] S2. Curing: Curing the concrete specimens in a standard curing room for 28 days (curing temperature 20°C±2°C, humidity ≥95%); the concrete specimens were taken out of the standard curing room 2 days before carbonization, and then placed at a temperature of 60°C Dry for 48 hours; after d...

Embodiment 2-9

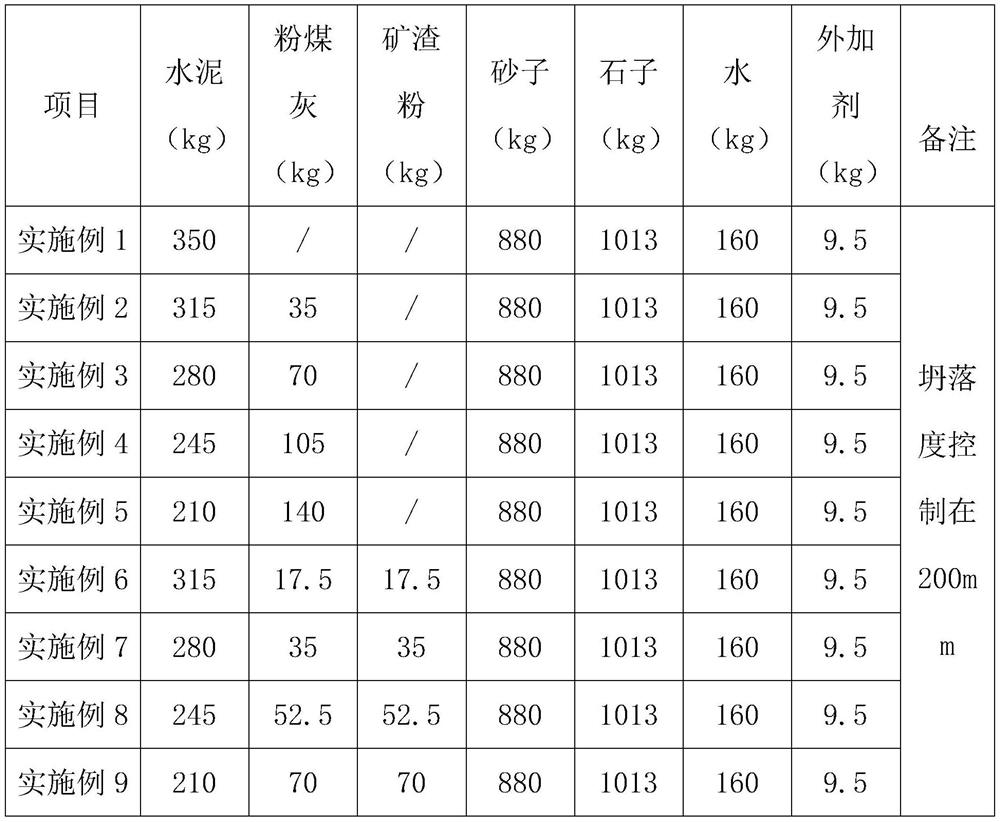

[0032] A method for measuring the depth of carbonation of a concrete test piece. The difference from Example 1 is that the proportion of raw materials for making the concrete test piece in S1 is different. The specific content is shown in Table 1; the measurement results are shown in Table 2.

[0033] Raw material components and proportioning of concrete test piece in table 1 embodiment 1-9

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com