Bulk density measuring device for latex powder production and detection

A technology for production detection and bulk density, which is used in measurement devices, specific gravity measurement, permeability/surface area analysis, etc., to solve the problems of latex powder being easily scattered, affecting the measurement accuracy, and inability to evenly pour into the container, reducing four The effect of drifting and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

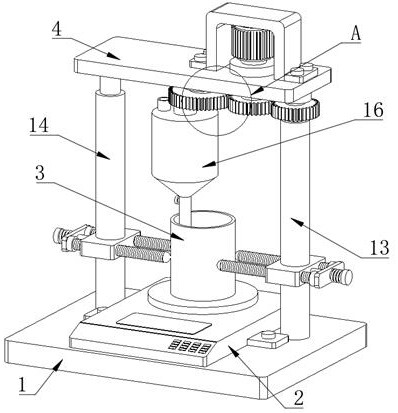

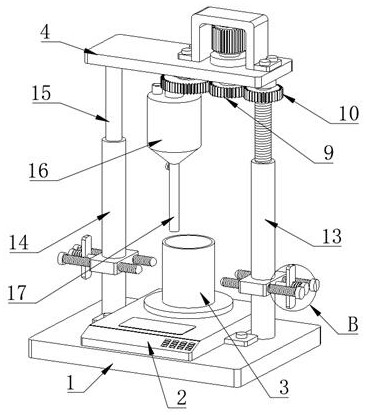

[0032] Such as Figure 1-8 As shown, a bulk density measuring device for latex powder production and testing includes a measuring platform 1 and a weighing device body 2, the weighing device body 2 is arranged on the top of the measuring platform 1, and the top of the weighing device body 2 is provided with a capacity cylinder 3. There is a supporting movable seat 4 above the capacity cylinder 3, and a connecting column 5 is arranged under the supporting movable seat 4. The bottom of the connecting column 5 is provided with a feeding mechanism, and the top of the connecting column 5 is fixedly connected with the first gear plate 6. , the top of the first gear plate 6 is fixedly connected with the first fixed shaft 7, the top of the first fixed shaft 7 is connected with the supporting movable seat 4 through the first bearing 8, and the axis centers of the connecting column 5 and the first fixed shaft 7 are inconsistent , one side of the first gear plate 6 is provided with a pos...

Embodiment 2

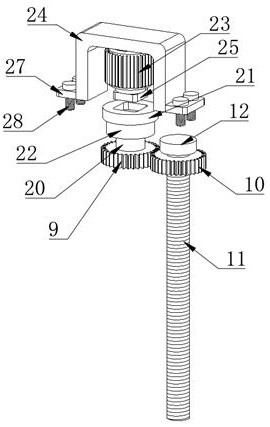

[0035] see Figure 1-8 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 1 , image 3 , Figure 4 and Figure 6 , the rotation drive mechanism includes a second fixed shaft 20 arranged on the top of the second gear plate 9, the second fixed shaft 20 is fixedly connected with the second gear plate 9, the top end of the second fixed shaft 20 runs through the supporting movable seat 4, and the second fixed shaft 20 A third bearing 22 is provided at the penetration of the shaft 20 and the supporting movable seat 4, and the top of the second fixed shaft 20 is fixedly connected with the first fixed plate 21 positioned at the top of the supporting movable seat 4, and the top of the first fixed plate 21 is provided with a mo...

Embodiment 3

[0037] see Figure 1-8 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. This Example 3 differs from Example 1 in that: Please refer to, figure 1 , figure 2 , Figure 7 and Figure 8 , the anti-slip mechanism includes a fixed plate 29 arranged on the top of the measuring platform 1, the threaded pipe 13 and the positioning pipe 14 run through the two fixed plates 29 respectively, and the two fixed plates 29 are respectively fixedly connected with the threaded pipe 13 and the positioning pipe 14, fixed One side of the plate 29 is provided with two second threaded columns 30, the second threaded columns 30 run through the fixed plate 29, the connection mode between the second threaded columns 30 and the fixed plate 29 is threaded connection, and the fixed plate 29 is far away from the end of the capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com