Plastic product quality detection method

A plastic product and quality technology, applied in the field of quality inspection of plastic products, can solve problems such as insufficient intelligence, inability to detect quality standards for plastic products, inaccurate test results, etc., and achieve the effect of standard detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

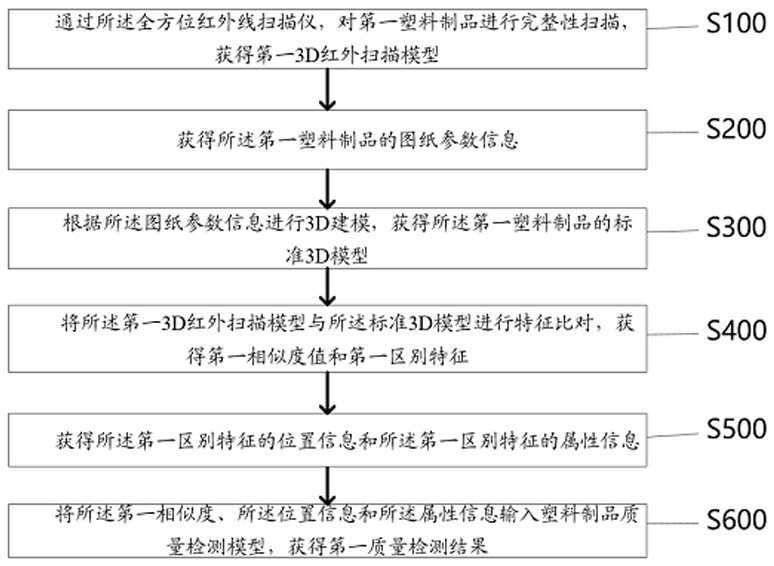

[0027] Such as figure 1 As shown, the embodiment of the present application provides a method for quality inspection of plastic products, wherein the method is applied to a quality inspection device for plastic products, and the device includes an omnidirectional infrared scanner. The method includes:

[0028] S100: Using the omni-directional infrared scanner, scan the integrity of the first plastic product to obtain a first 3D infrared scanning model, wherein the first 3D infrared scanning model is the first plastic product in a first posture Obtained by the omni-directional infrared scanner;

[0029] Specifically, the above-mentioned first plastic product is any plastic product prepared and molded by a plastic molding process in the prior art, for example, it includes plastic containers in daily life, plastic gears in industry, plastic special-shaped parts, etc., The use of the above-mentioned plastic products has strict requirements on their appearance standards, and the a...

Embodiment 2

[0088] Based on the same inventive concept as the quality detection method of a plastic product in the foregoing embodiment, as Figure 5 As shown, the embodiment of the present application provides a quality detection device for plastic products, wherein the device includes:

[0089] The first obtaining unit 11, the first obtaining unit 11 is used to scan the integrity of the first plastic product through the omnidirectional infrared scanner to obtain the first 3D infrared scanning model, wherein the first 3D infrared scanning model The scanning model is obtained by passing the omni-directional infrared scanner according to the first attitude of the first plastic product;

[0090] A second obtaining unit 12, the second obtaining unit 12 is configured to obtain drawing parameter information of the first plastic product;

[0091] A first processing unit 13, the first processing unit 13 is configured to perform 3D modeling according to the drawing parameter information, and obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com