Low-voltage transformer area load non-power-cut switching system and working method thereof

A low-voltage station area and switching system technology, applied in the direction of power network operating system integration, information technology support systems, electrical components, etc., can solve problems affecting system stability, increase live working steps and safety risks, and safety shackles, etc., to achieve Improve reliability and safety, simplify live working steps, and increase the effect of application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

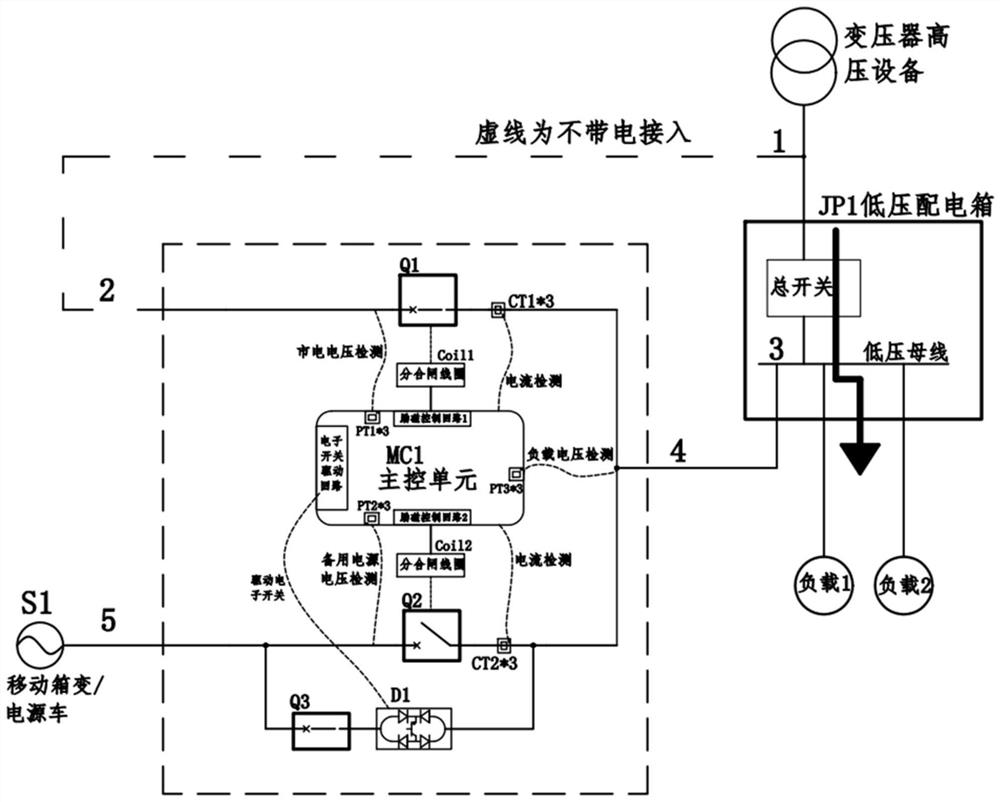

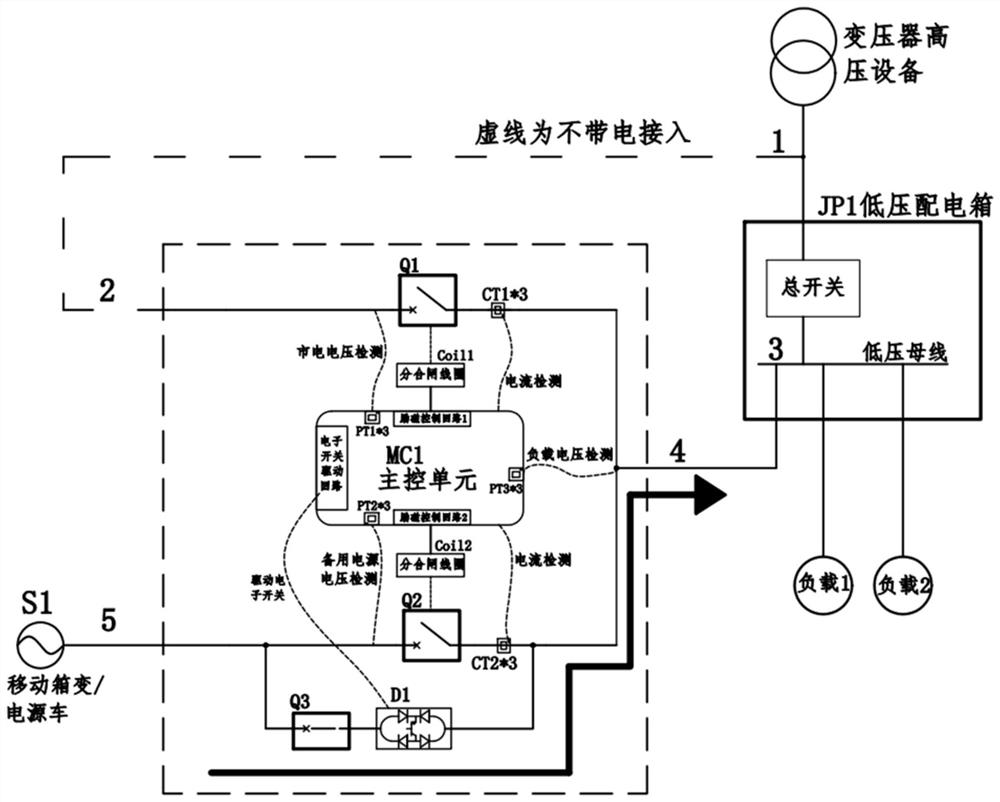

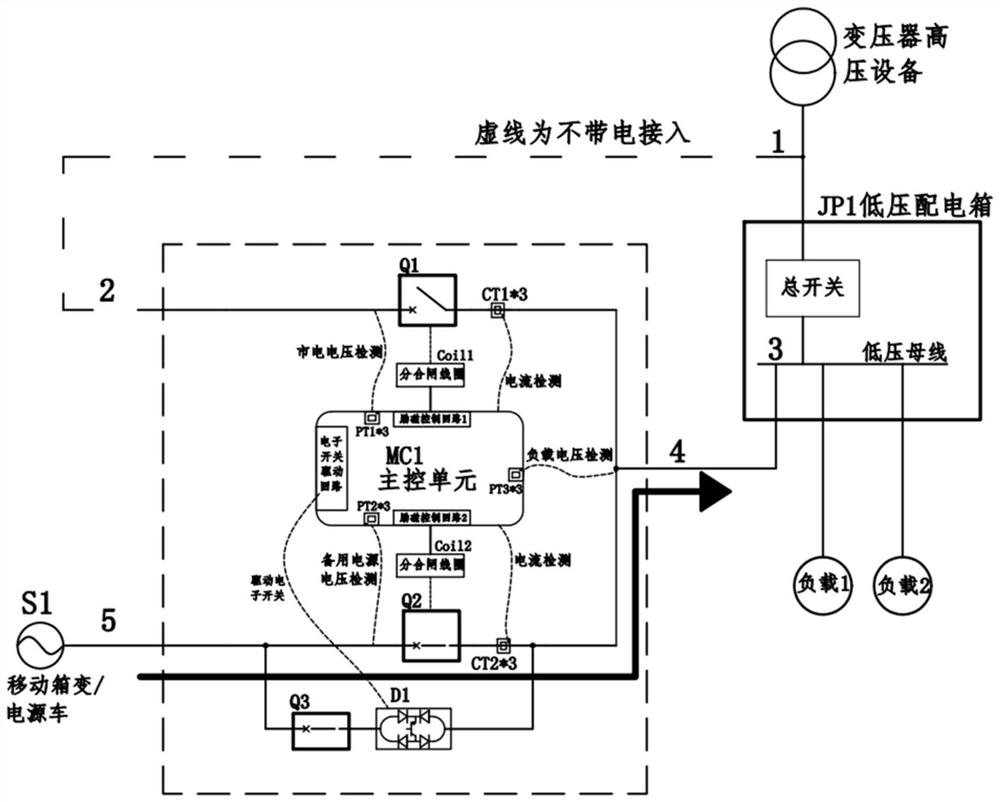

[0047] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings.

[0048] like figure 1 As shown, the present invention mainly includes a primary conductive branch, a short-time conductive branch, a market electrolyte, a control circuit, and a current / voltage signal acquisition module;

[0049] Where: the primary electric branch includes a second circuit breaker Q2; one end of the second circuit breaker Q2 is connected to the moving box change / power vehicle S1; the other end of the second circuit breaker Q2 is connected to the low voltage distribution box JP1;

[0050] The short-time conductive branch includes an electron solid state switch D1 and a first circuit breaker Q1; short-time conductive branch and the second circuit breaker Q2 are parallel;

[0051] The main circuit bypass includes a first circuit breaker Q1; one end of the first circuit breaker Q1 is connected to the low voltage distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com