System, method and device for adjusting flow of parallel branch of double-phase cold plate liquid cooling system

A branch flow and liquid cooling technology, which is applied in the direction of using liquid cooling for modification, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of induced air plug load temperature, poor adjustment effect, load frequency reduction, etc., to achieve Effect of improving reliability and safety, simple structure, and avoiding delay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

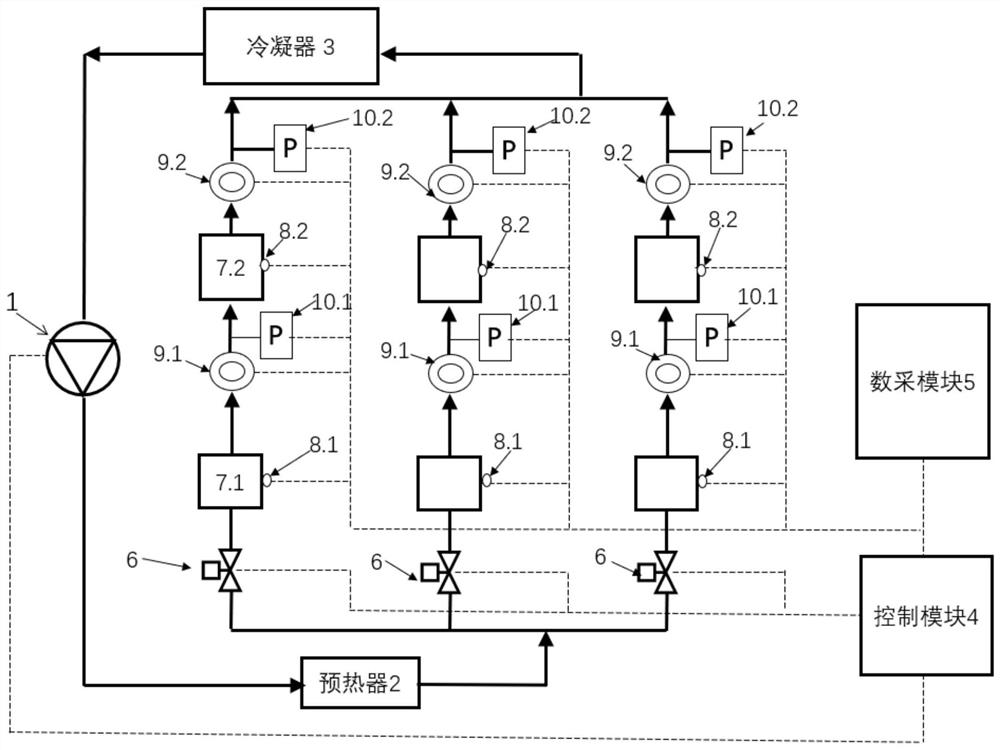

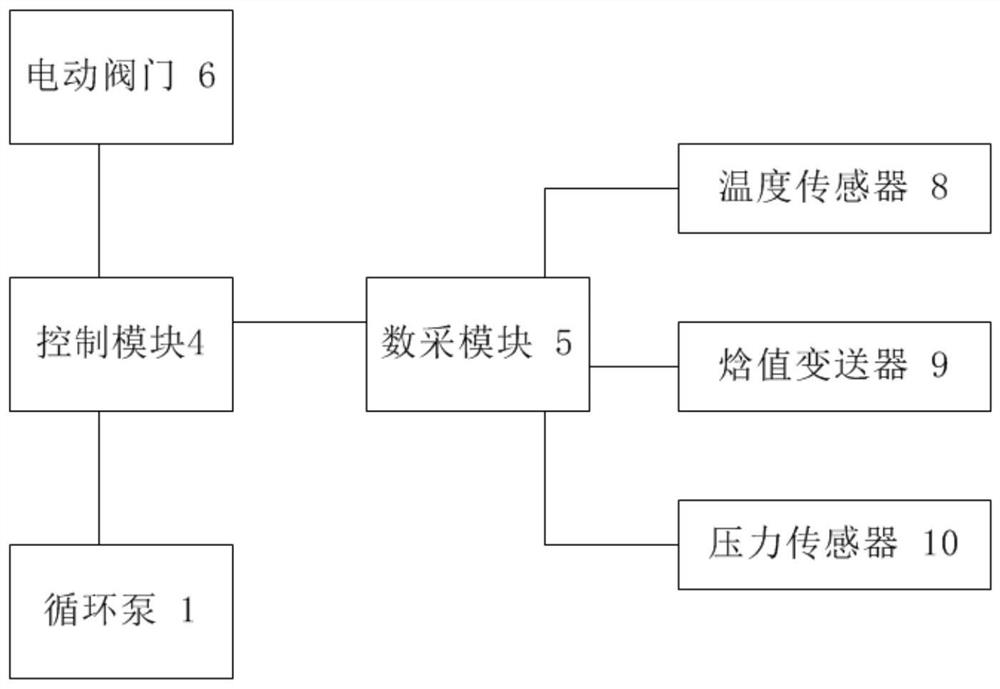

[0071] Such as figure 1 with figure 2 As shown, the present invention provides a system for adjusting the flow rate of the parallel branch of the two-phase cold plate liquid cooling system, including a circulating pump 1, a preheater 2, a condenser 3, a two-phase cold plate liquid cooling parallel branch, and a control module 4 And the data acquisition module 5;

[0072] The first end of the circulation pump 1 is connected to the preheater 2, and the second end of the circulation pump 1 is connected to the condenser 3;

[0073] The two-phase cold plate liquid-cooled parallel branch circuit includes several cooling branches, the first ends of each cooling branch are connected and connected with the preheater 2; the second ends of each cooling branch are connected and connected with the condenser 3;

[0074] Electric valves 6 and several evaporators 7 are respectively arranged on each cooling branch, and temperature sensors 8 are arranged at the evaporators 7;

[0075] The e...

Embodiment 2

[0079] Such as figure 1 As shown, the present invention provides a system for adjusting the flow rate of the parallel branch of the two-phase cold plate liquid cooling system, including a circulating pump 1, a preheater 2, a condenser 3, a two-phase cold plate liquid cooling parallel branch, and a control module 4 And the data acquisition module 5;

[0080] The first end of the circulation pump 1 is connected to the preheater 2, and the second end of the circulation pump 1 is connected to the condenser 3;

[0081] The two-phase cold plate liquid-cooled parallel branch circuit includes several cooling branches, the first ends of each cooling branch are connected and connected with the preheater 2; the second ends of each cooling branch are connected and connected with the condenser 3;

[0082] Electric valves 6 and several evaporators 7 are respectively arranged on each cooling branch, and temperature sensors 8 are arranged at the evaporators 7;

[0083] The electric valve 6 ...

Embodiment 3

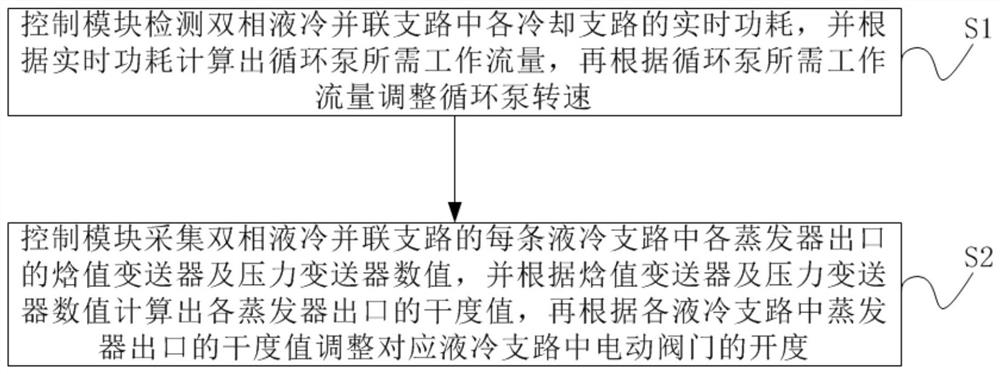

[0091] Such as image 3 As shown, the present invention provides a method for adjusting the parallel branch flow of a two-phase cold plate liquid cooling system, comprising the following steps:

[0092] S1. The control module detects the real-time power consumption of each cooling branch in the two-phase liquid cooling parallel branch, and calculates the required working flow of the circulating pump according to the real-time power consumption, and then adjusts the circulating pump speed according to the required working flow of the circulating pump;

[0093] S2. The control module collects the values of the enthalpy transmitters and pressure transmitters at the outlets of the evaporators in each liquid cooling branch of the two-phase liquid cooling parallel branch, and according to the values of the enthalpy transmitter and the pressure transmitter Calculate the dryness value of each evaporator outlet, and then adjust the opening of the electric valve in the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com