Partition type beverage filling equipment capable of conveniently adjusting volume

A filling equipment and partition type technology, which is applied in the field of partition type beverage filling equipment, can solve the problems of contact between the liquid in the can and the air, and it is difficult to grasp the filling volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

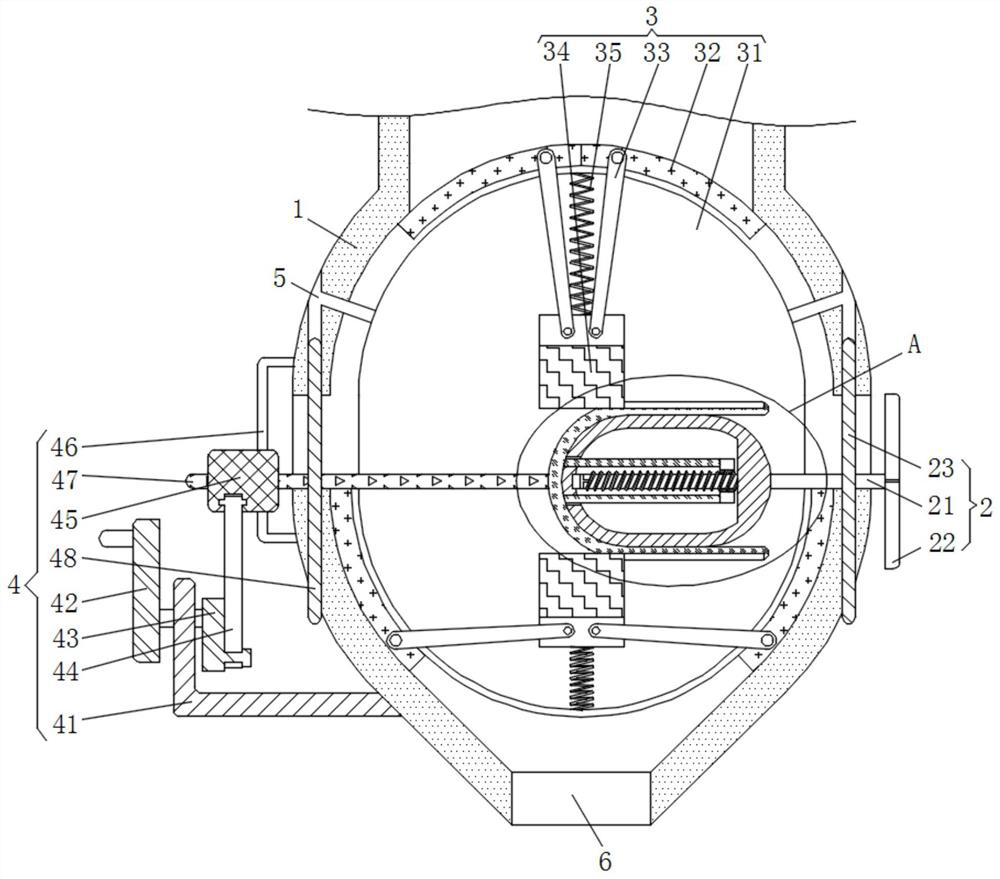

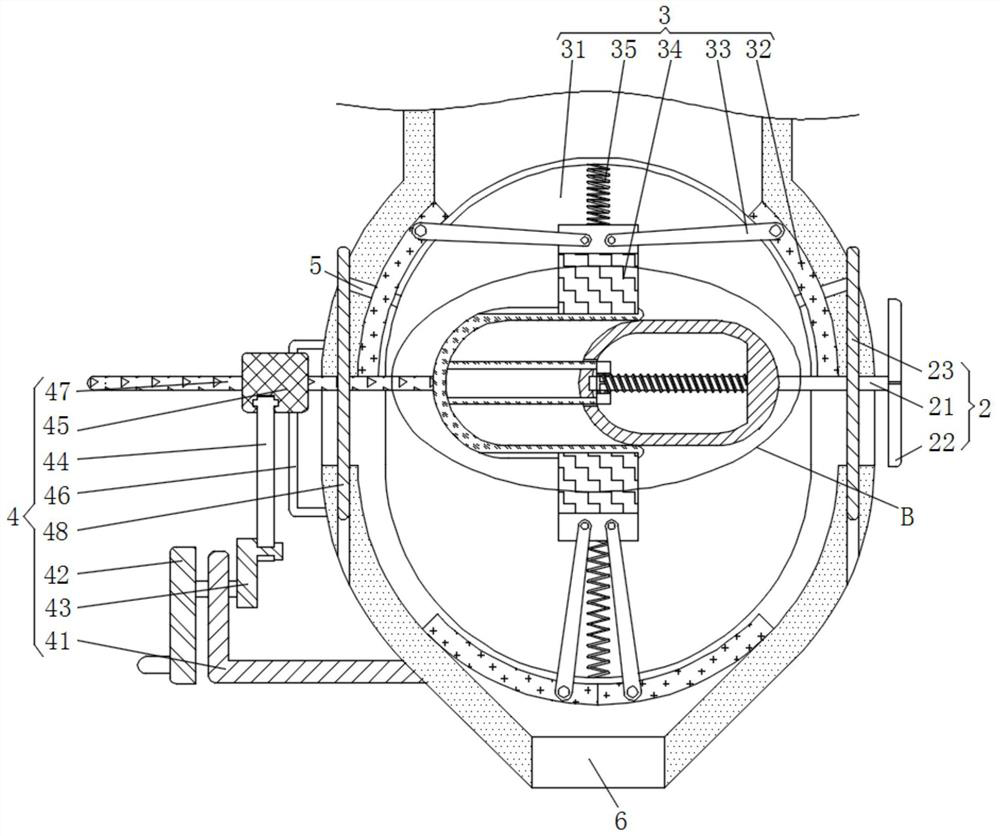

[0026] see figure 1 , 3 , 4 and 5, a partition type beverage filling equipment that is convenient for volume adjustment, including a housing 1, the right end of the housing 1 is rotatably connected with a quantitative mechanism 2, and the quantitative mechanism 2 includes a rotating shaft 21, a knob 22, and a stopper 23 , hollow block 24, screw rod 25, slide block 26, pole 27, sleeve 28, limit groove 29, the right end of rotating shaft one 21 is fixedly connected with knob 22, and the periphery of rotating shaft one 21 middle part is slidingly connected with stop plate one 23, The left end periphery of rotating shaft one 21 is rotatably connected with hollow block 24, and the left end of rotating shaft one 21 is fixedly connected with screw rod 25, and the peripheral screw thread of screw rod 25 is connected with slide block 26, and the left end of slide block 26 is fixedly connected with support rod 27, and support rod 27 The left end of the sleeve 28 is fixedly connected wi...

Embodiment 2

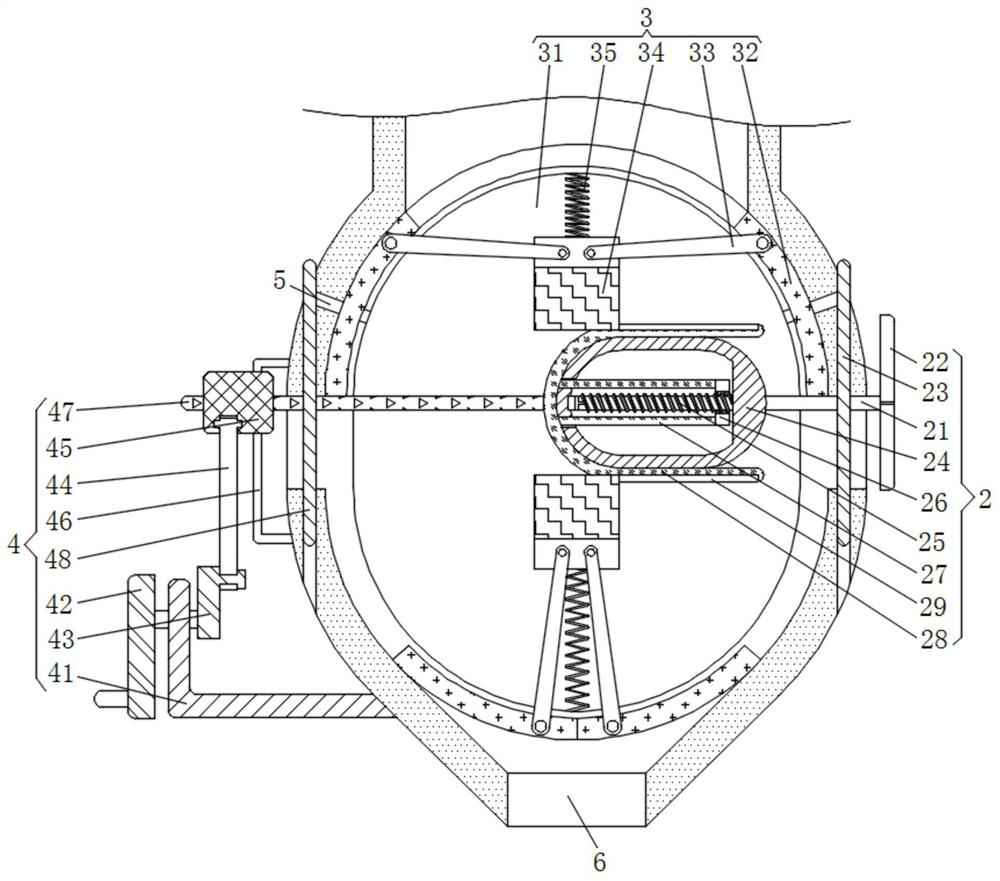

[0028] see Figure 1-2, a partition type beverage filling equipment that is convenient for volume adjustment, including a housing 1, the right end of the housing 1 is rotatably connected with a quantitative mechanism 2, and the upper and lower ends of the housing 1 are provided with a communication mechanism 3, the communication mechanism 3 includes a cavity 31. Stopper 32, connecting rod one 33, movable block 34, spring one 35, the upper and lower inner walls of the cavity 31 are connected with stoppers 32, and the end of the stopper 32 close to the center of the housing 1 is hinged with a connecting rod one 33, the other end of the connecting rod 33 is hinged with a movable block 34, and the end of the movable block 34 close to the stopper 32 is elastically connected with a spring 135, the stopper 32 is arranged symmetrically about the horizontal center of the housing 1, and the stopper 32 is close to the housing 1 Center one end is connected with movable piece 34 by connect...

Embodiment 3

[0030] see Figure 1-5 , a partition type beverage filling equipment that is convenient for volume adjustment, including a housing 1, the right end of the housing 1 is rotatably connected with a quantitative mechanism 2, and the quantitative mechanism 2 includes a rotating shaft 21, a knob 22, a stopper 23, and a hollow block 24 , screw rod 25, slide block 26, pole 27, sleeve 28, limit groove 29, the right end of rotating shaft one 21 is fixedly connected with knob 22, and the periphery of rotating shaft one 21 middle part is slidingly connected with retaining plate one 23, and rotating shaft one 21 The left end periphery is rotatably connected with hollow block 24, and the left end of rotating shaft 21 is fixedly connected with screw rod 25, and the peripheral thread of screw rod 25 is connected with slide block 26, and the left end of slide block 26 is fixedly connected with strut 27, and the left end of strut 27 is fixedly connected with There is a sleeve 28, the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com