High-precision remote intelligent control equipment for microbial strain production workshop

A technology of remote intelligent control and microbial strains, applied in biochemical equipment and methods, enzymology/microbiology devices, biomass post-processing, etc., to achieve simple and convenient operation and better cultivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

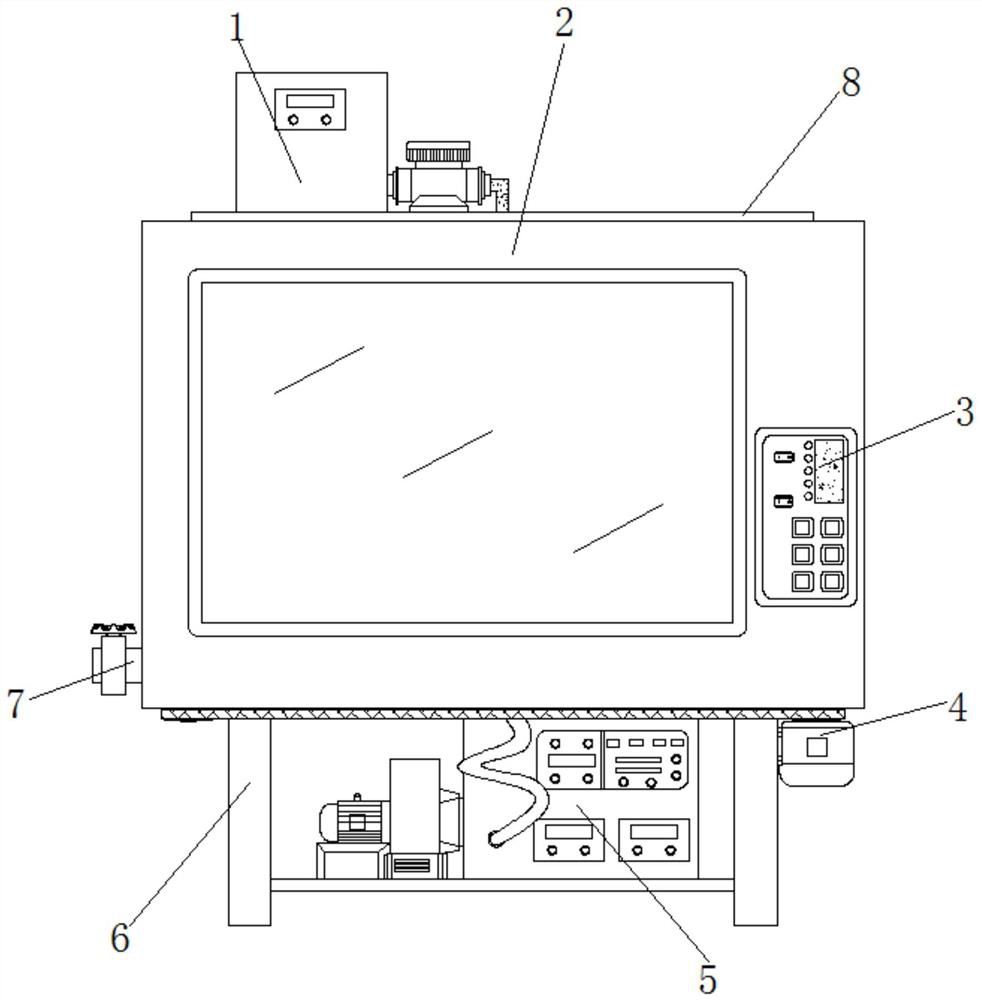

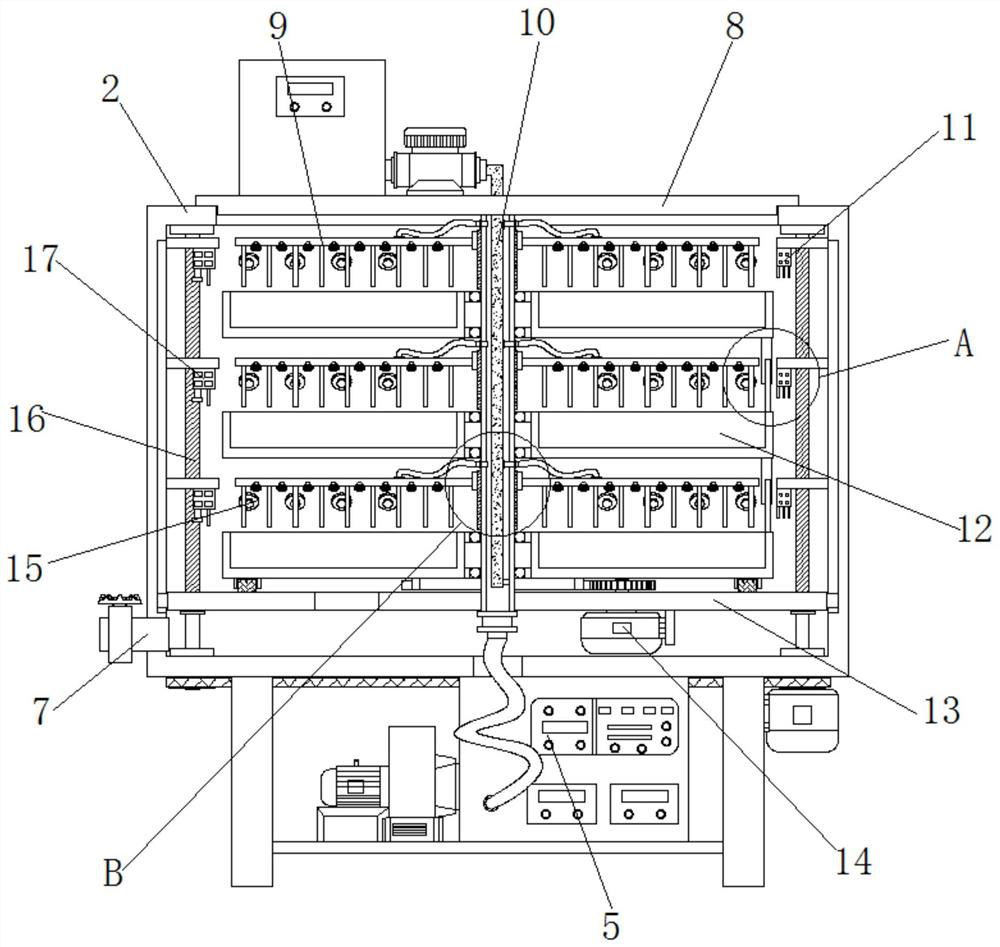

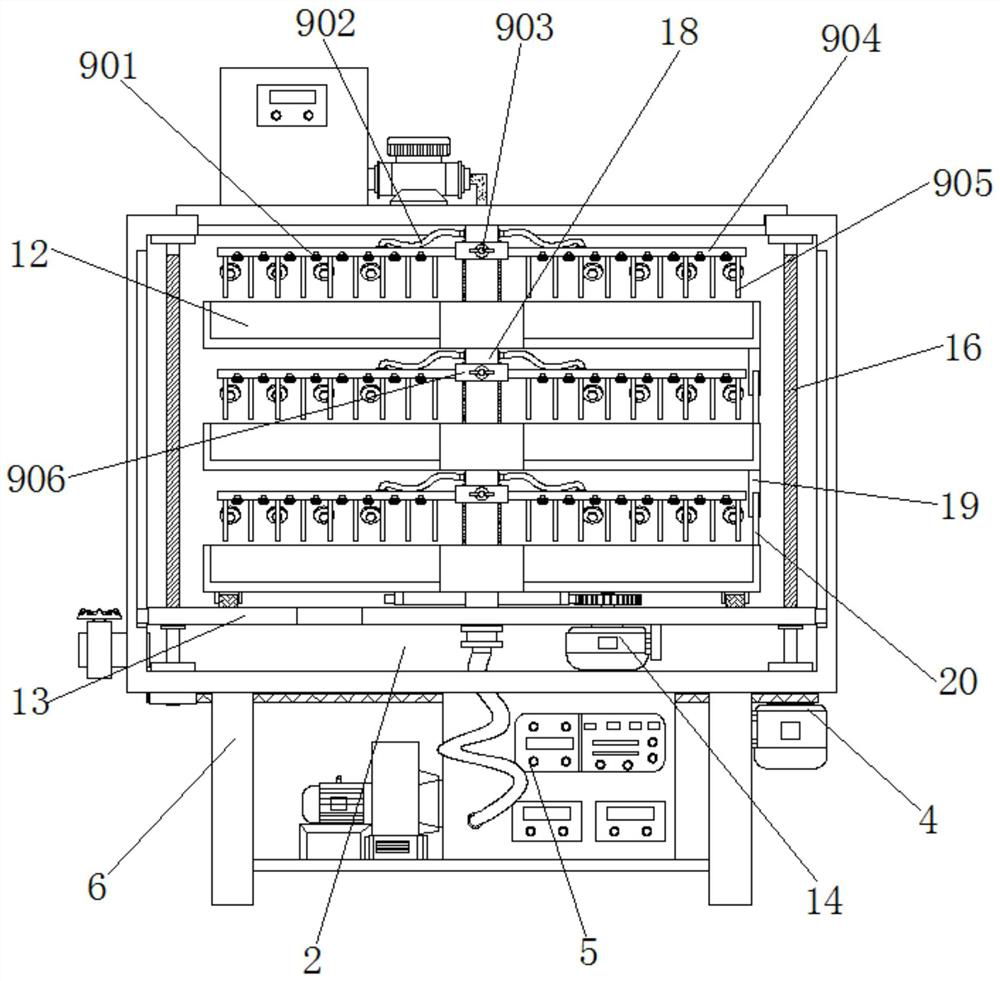

Embodiment 1

[0040] Example 1, such as figure 2 , 3 , 4, 6 and 9, control the second driving device 4 to drive four sets of threaded rods 16 to rotate synchronously in the same direction, thereby forcing the movable plate 13 to gradually rise inside the main body compartment 2, so that the three groups of placement trays 12 are lifted from the main body compartment 2 protrudes from the top, and then the operator lays the microbial strains on the inner bottom of the storage tray 12 in an orderly manner, and then controls the three sets of placement trays 12 to descend to the inside of the main compartment 2 again, and the top plate 8 is covered on the bottom of the main compartment 2 again. At the top, if you want to take out the microbial strains cultivated inside the placement tray 12, after controlling the three groups of placement trays 12 to protrude from the top of the main body compartment 2, manually lift the movable ring 906 so that the stirring rods 905 all leave the placement tr...

Embodiment 2

[0041] Example 2, such as figure 2 , 3 , 4, 6, 7, 8 and 9, when it is necessary to improve the contact effect of the microorganisms in the tray 12 and the hot and humid air, the first driving device 14 is controlled to drive a group of placement trays 12 at the bottom to slowly rotate, and the bottom One set of placing trays 12 drives the other two sets of placing trays 12 to rotate together in the same direction through the transmission of the driven push rod 19 and the driving push rod 20, so that hot air and water mist can be evenly sprayed on the microbial strains, and in three When the group of placing trays 12 rotates in the same direction, since the stirring rods 905 at the bottom of the conveying pipe 904 all extend into the inside of the placing tray 12, the placing tray 12 is in the process of rotating, so that multiple groups of stirring rods 905 are aligned with the inside of the placing tray 12. The microbial strains in the bottom layer play the role of stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com