A method for preparing non-oriented electrical steel with high magnetic induction and high strength by step-by-step regulation

A kind of oriented electrical steel, high-strength technology, applied in the field of electrical steel manufacturing, can solve the problems of difficulty in both, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

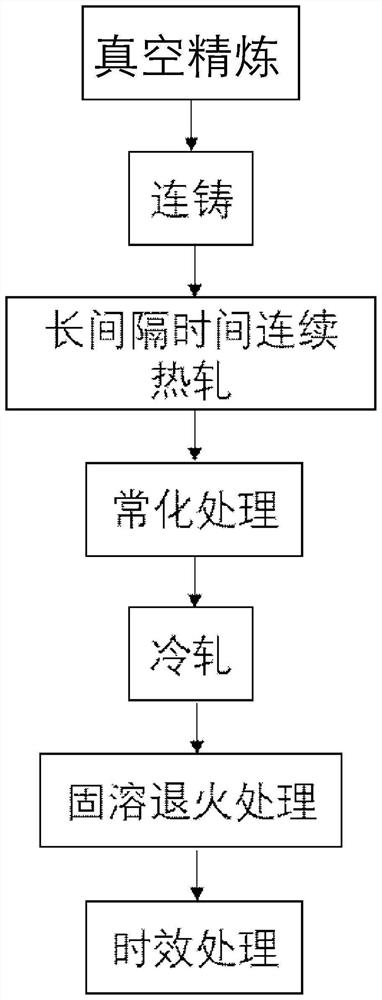

[0041] Process such as figure 1 shown;

[0042]The molten steel is smelted in a converter according to the set composition, and the harmful gases in the steel are removed by RH vacuum refining treatment, and then subjected to decarburization, dephosphorization and desulfurization, and finally continuous casting is carried out to form a continuous casting billet; 0.005%, Si3.4%, Cu1.1%, Ni 0.8%, Al 0.5%, Mn 0.8%, P 0.004%, S 0.003%, the rest are Fe and inevitable impurities;

[0043] The thickness of the continuous casting billet is 80mm;

[0044] The continuous casting billet is placed in a soaking furnace, kept at 1000 ° C for 90 minutes, and then multi-pass hot rolling is carried out. The rolling temperature is 720-1080 ° C, and the interval between two adjacent passes of hot rolling. is 90s; air-cooled to room temperature after hot rolling, and made into a hot-rolled sheet, the thickness of the hot-rolled sheet is 3mm; the total reduction rate is 96.25%;

[0045] The hot...

Embodiment 2

[0053] The method is the same as in Example 1, except that:

[0054] (1) The continuous casting billet contains C 0.006%, Si 1.52%, Cu 0.8%, Ni 0.6%, Al0.2%, Mn 1.0%, P 0.003%, S 0.002% by mass percentage; the thickness of the continuous casting billet is 150mm ;

[0055] (2) The soaking furnace is kept at 900°C for 120min, and the interval between two adjacent passes of hot rolling is 60s; the thickness of the hot-rolled sheet is 5mm; the total reduction rate of hot-rolling is 96.7%;

[0056] (3) Normalization treatment at 1050°C for 60min; the volume concentration of hydrogen in the mixed atmosphere is 30%;

[0057] (4) The total reduction ratio of cold rolling is 90%; the thickness of cold rolling sheet is 0.50mm;

[0058] (5) annealing at 1050°C for 5 minutes; the volume concentration of hydrogen in the mixed atmosphere is 30%;

[0059] (6) The annealed sheet is kept at 600°C for 15min for aging treatment;

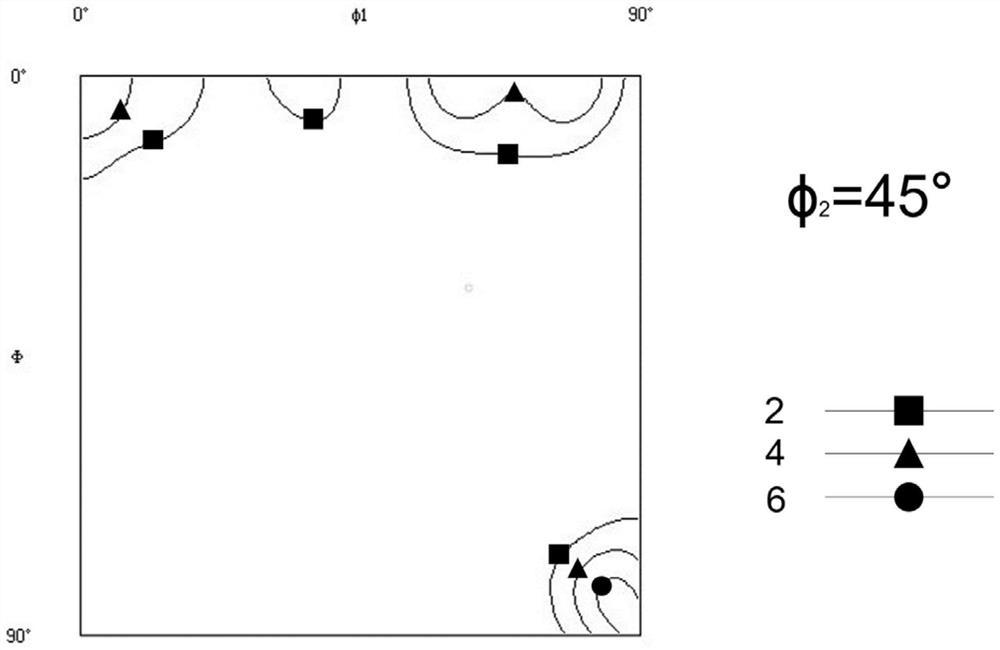

[0060] The λ texture component ratio of high magnetic inducti...

Embodiment 3

[0064] The method is the same as in Example 1, except that:

[0065] (1) The continuous casting billet contains C 0.002%, Si 3.12%, Cu 1.32%, Ni 1.4%, Al0.3%, Mn 0.5%, P 0.002%, S 0.004% by mass percentage; the thickness of the continuous casting billet is 300mm ;

[0066] (2) The soaking furnace is kept at 1100°C for 60 minutes, and the interval between two adjacent passes of hot rolling is 45s; the thickness of the hot-rolled sheet is 3.6mm; the total hot-rolling reduction rate is 98.8%;

[0067] (3) Normalization treatment at 900°C for 120min; the volume concentration of hydrogen in the mixed atmosphere is 50%;

[0068] (4) The total reduction ratio of cold rolling is 73.3%; the thickness of cold rolling sheet is 0.10mm;

[0069] (5) annealing at 1030°C for 15min; the volume concentration of hydrogen in the mixed atmosphere is 50%;

[0070] (6) The annealed sheet is kept at 500°C for 25min for aging treatment;

[0071] The λ texture component ratio of high magnetic indu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com