Mg-Mn-Er wrought magnesium alloy and preparation method thereof

A deformed magnesium alloy, mg-mn-er technology, applied in the field of magnesium alloy materials, can solve the problems of poor plastic deformation ability of magnesium alloy, difficulty in preparing large samples, strong texture of magnesium alloy, etc., to achieve deformation process improvement, The preparation method is simple and easy to operate, and the effect of improving the alloy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

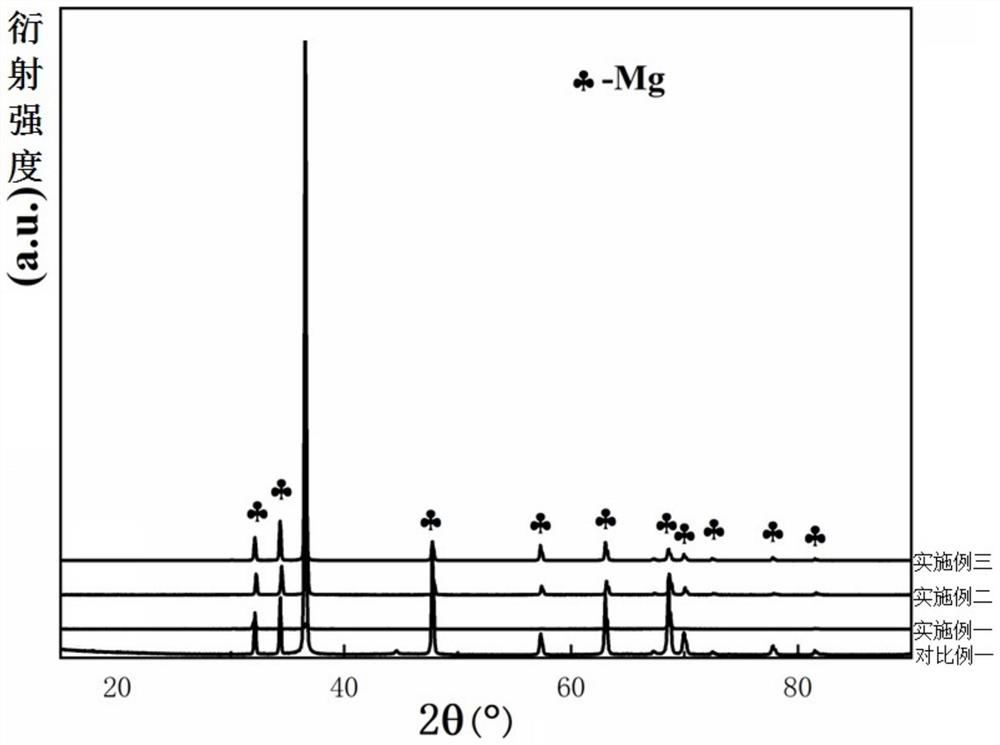

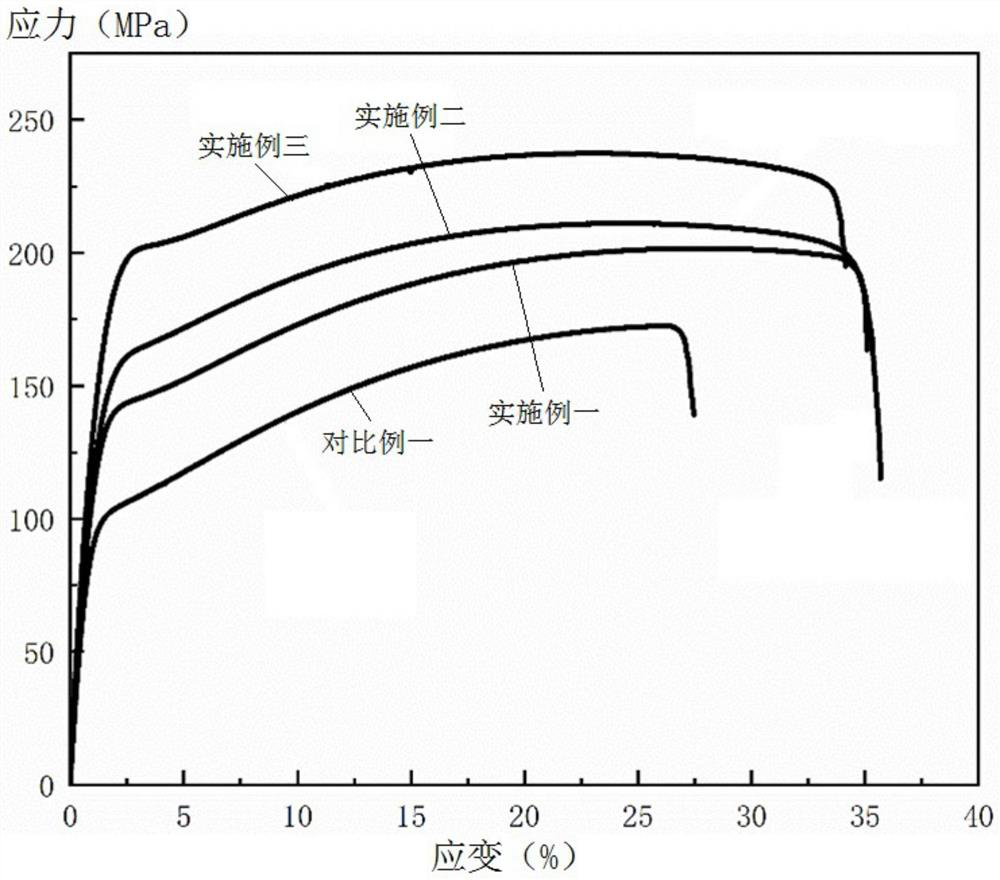

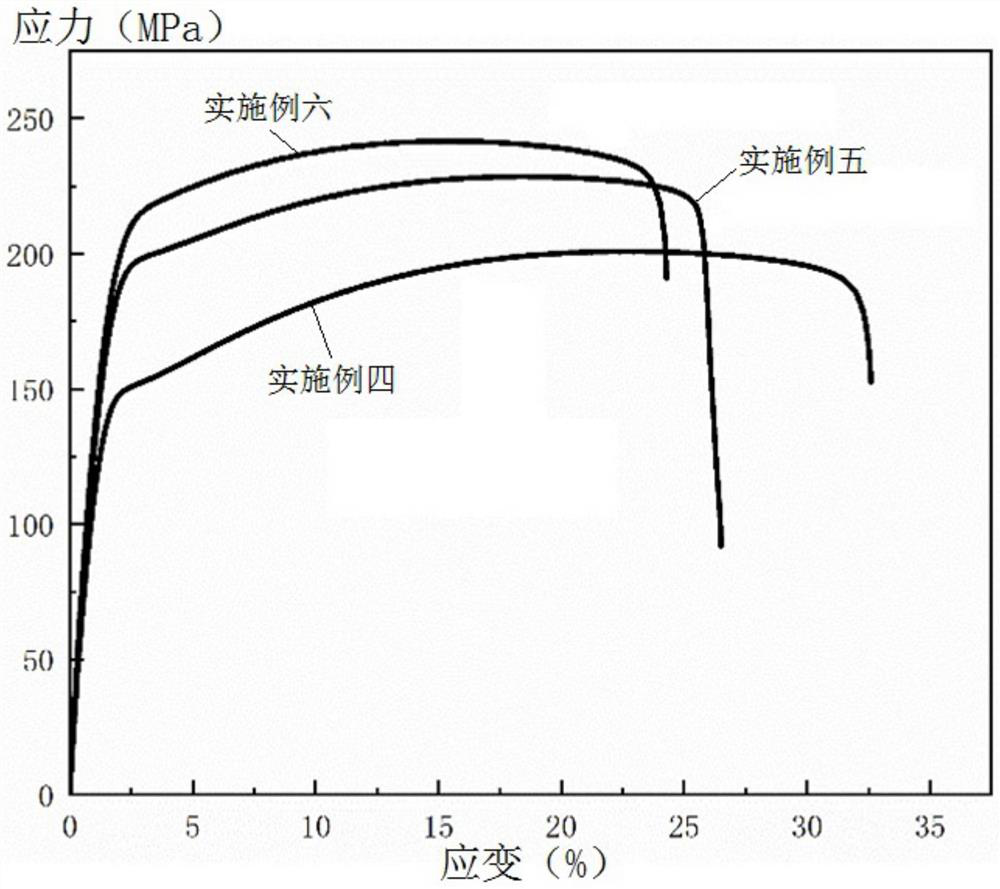

Embodiment 1

[0026] Embodiment 1, a Mg-Mn-Er series deformed magnesium alloy, comprises the following components by weight percentage: 0.3% Mn, 2% Er, the balance is Mg and unavoidable impurities. The preparation method of the magnesium alloy includes the following steps.

[0027] S1, raw material preparation, weighing pure magnesium ingot, magnesium-manganese master alloy and magnesium-erbium master alloy according to the composition distribution ratio of the above-mentioned Mg-Mn-Er series deformed magnesium alloy. The weight percent of Mn in the magnesium-manganese master alloy is 3%, and the weight percent of Er in the magnesium-erbium master alloy is 20%.

[0028] S2, smelting, preheat the pure magnesium ingot at a temperature of 300°C for 30 minutes, and then heat the pure magnesium ingot at 720-750°C with SF 6 and CO 2 Under the protection of the mixed gas, it is completely melted to obtain a magnesium melt. After the temperature of the magnesium melt is raised to 720°C and stabil...

Embodiment 2

[0031] Embodiment 2, a Mg-Mn-Er series deformed magnesium alloy, comprising the following components by weight percentage: 0.6% of Mn, 2% of Er, and the balance of Mg and unavoidable impurities. Its preparation method is identical with embodiment one.

Embodiment 3

[0032] Embodiment 3, a Mg-Mn-Er series wrought magnesium alloy, comprising the following components by weight percentage: 0.9% Mn, 2% Er, the balance being Mg and unavoidable impurities. Its preparation method is identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com