EW460 extra-thick maritime steel plate and manufacturing method thereof

A manufacturing method and steel plate technology, applied in the direction of manufacturing tools, temperature control, metal rolling, etc., can solve problems such as ambiguity, achieve excellent mechanical properties, improve the shape of inclusions, and have wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

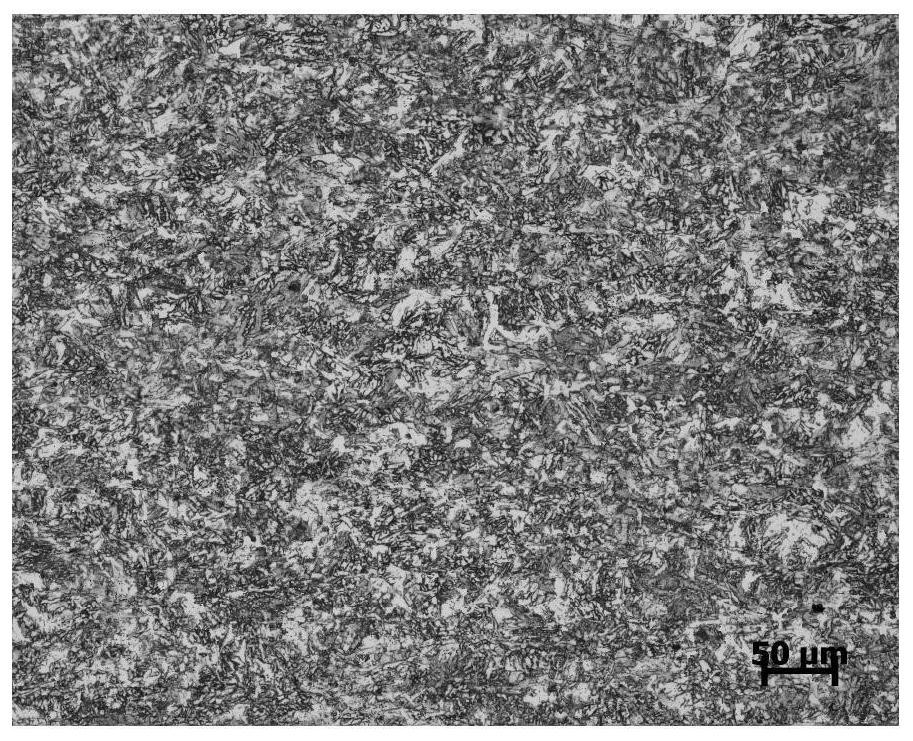

Embodiment 1

[0024] The production method of the 81mm thick EW460 extra-thick marine steel plate of embodiment 1 is specifically as follows:

[0025] Steelmaking and continuous casting process: after desulfurization of molten iron, the target sulfur is 0.002%; converter smelting adopts high-blowing and low-drawing method for dephosphorization, the drain port is clean and free of defects, converter tapping slag; refining adopts white slag operation, and the white slag retention time is 20 minutes , the target alkalinity is 5; the holding time of vacuum treatment is 25 minutes; seamless calcium line treatment is carried out after vacuum treatment; five-hole nozzle is used for casting, the target temperature of continuous casting tundish is liquidus temperature + 15 ℃, and the casting speed is stable;

[0026] Rolling process: controlled rolling and controlled cooling process is adopted, which is two-stage rolling; the heating temperature of the continuous casting slab before rolling is 1180 ℃...

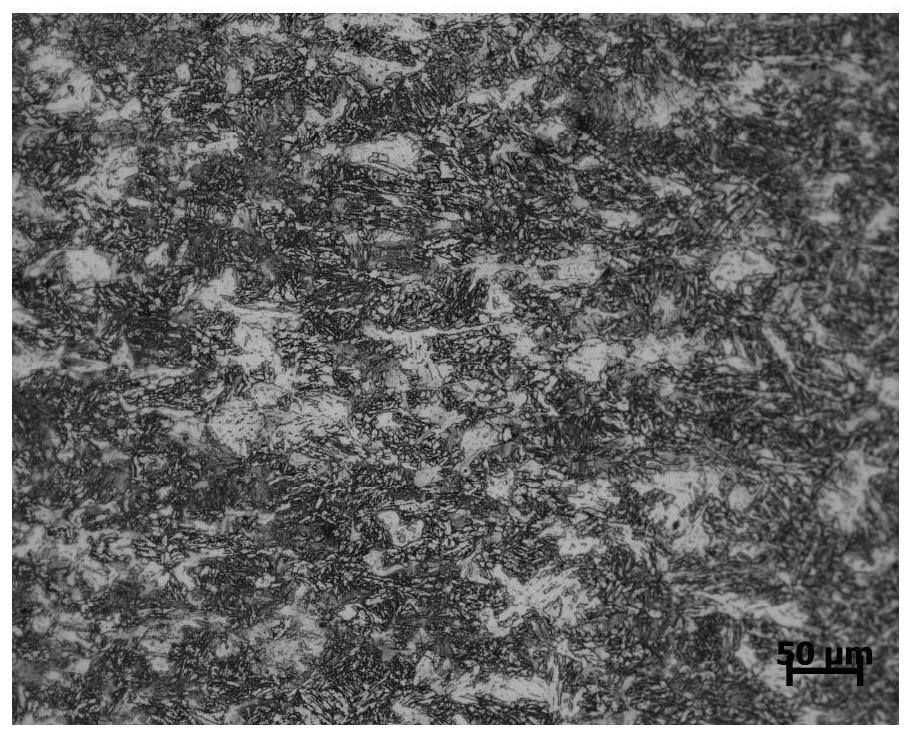

Embodiment 2

[0027] The production method of the 90mm thick EW460 extra-thick marine steel plate of embodiment 2 is specifically as follows:

[0028] Steelmaking and continuous casting process: after desulfurization of molten iron, the target sulfur is 0.0017%; converter smelting adopts high-blowing and low-drawing method for dephosphorization, the drain port is clean and free of defects, converter tapping slag; refining adopts white slag operation, white slag retention time is 22 minutes , the target alkalinity is 6; the holding time of vacuum treatment is 30 minutes; seamless calcium line treatment is carried out after vacuum treatment; casting uses five-hole nozzles, the target temperature of continuous casting tundish is liquidus temperature + 10 ℃, and the casting speed is stable;

[0029] Rolling process: controlled rolling and controlled cooling process is adopted, which is two-stage rolling; the heating temperature of continuous casting slab before rolling is 1130 ℃; the rough rolli...

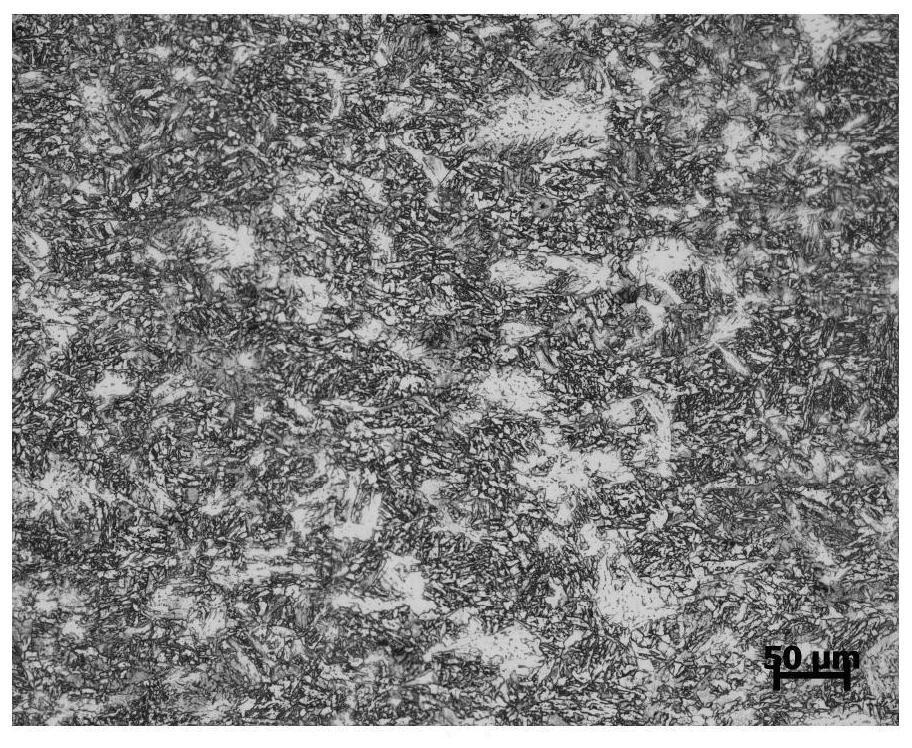

Embodiment 3

[0030] The production method of the 100mm thick EW460 extra-thick marine steel plate of embodiment 3 is specifically as follows:

[0031]Steelmaking and continuous casting process: after desulfurization of molten iron, the target sulfur is 0.0015%; converter smelting adopts high-blowing and low-drawing method for dephosphorization, the drain port is clean and free of defects, converter tapping slag; refining adopts white slag operation, white slag retention time is 24 minutes , the target alkalinity is 7; the holding time of vacuum treatment is 34 minutes; seamless calcium line treatment is carried out after vacuum treatment; five-hole nozzle is used for casting, the target temperature of continuous casting tundish is liquidus temperature + 5 ℃, and the casting speed is stable;

[0032] Rolling process: controlled rolling and controlled cooling process is adopted, which is two-stage rolling; the heating temperature of the continuous casting slab before rolling is 1110 ℃; the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com