Heat treatment method for improving corrosion resisting property of in-situ AlN/AZ91 magnesium matrix composite

A heat treatment method and composite material technology are applied in the field of heat treatment to improve the corrosion resistance of in-situ AlN/AZ91 magnesium matrix composite materials. Problems such as poor performance and limiting the wide application of magnesium alloys can achieve the effect of optimizing the solution treatment and aging treatment processes, improving the corrosion resistance, and the process parameters are feasible.

Inactive Publication Date: 2019-08-30

NORTHWESTERN POLYTECHNICAL UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, magnesium alloys have been widely used in aviation, aerospace, rockets, missiles, automobile industry, electronics industry and other fields due to their many excellent characteristics. The highest, which also determines the poor corrosion resistance of magnesium alloys

This puts forward higher requirements for the working environment of magnesium alloys. The working environment of magnesium alloys should not be too harsh, and can only be used in places with relatively mild working environments, which greatly limits the wide application of magnesium alloys.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

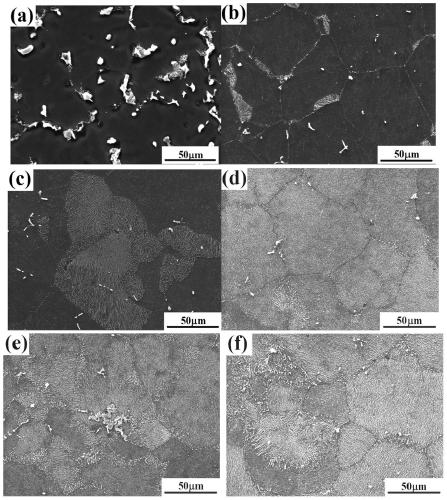

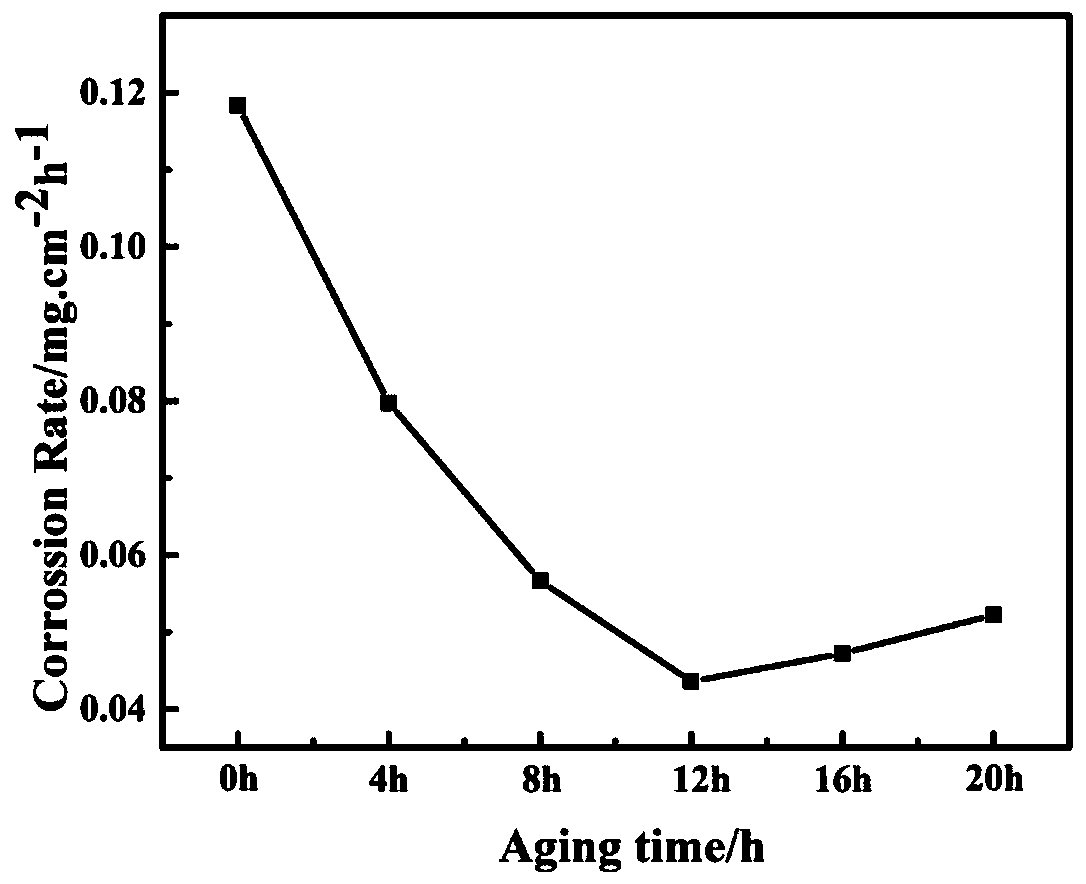

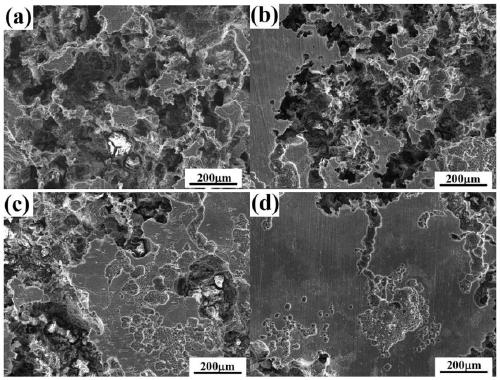

[0038] Example 1: Solution treatment: 415°C×24h; aging treatment: 220°C×4h; see figure 1 and image 3 b map;

Embodiment 2

[0039] Example 2: Solution treatment: 415°C×24h; aging treatment: 220°C×8h; see figure 1 and image 3 c map of

Embodiment 3

[0040] Example 3: Solution treatment: 415°C×24h; aging treatment: 220°C×12h; figure 1 and image 3 The d map;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a heat treatment method for improving a corrosion resisting property of an in-situ AlN / AZ91 magnesium matrix composite. An AlN / AZ91 magnesium matrix composite ingot casting (patent ZL201510882938.5) serves as a raw material, through formulating particular parameters of solid solution temperature, solid solution time, aging temperature, aging time and the like, the heat treatment process for improving the corrosion resisting property of the AlN / AZ91 magnesium matrix composite is formed. The process parameters of the heat treatment process are practicable and easy to control, compared with a cast-state AlN / AZ91 magnesium matrix composite, the corrosion resistance property can be obviously improved, and improvement of the corrosion resisting property of the AlN / AZ91 magnesium matrix composite can be achieved.

Description

technical field [0001] The invention belongs to a heat treatment method for the corrosion resistance of magnesium-based composite materials, and relates to a heat treatment method for improving the corrosion resistance of in-situ AlN / AZ91 magnesium-based composite materials. ZL 201510882938.5), using a solid solution + aging heat treatment process to improve the corrosion resistance of AlN / AZ91 magnesium matrix composites. Background technique [0002] As the lightest structural engineering material, magnesium alloy has a series of advantages, such as: low density, high specific strength and specific height, good electrical conductivity, easy recycling, etc., and is widely used in aviation, aerospace, rocket, missile, automobile industry, 3C and other fields. However, the standard electrode potential of magnesium alloy is extremely low, and it is one of the most active metal materials among common structural metals. It will be corroded to varying degrees in humid air, acidi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22F1/06C22F1/02

CPCC22F1/002C22F1/02C22F1/06

Inventor 杨长林孙云霞张斌徐鑫玥闫益泽刘峰

Owner NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com