A nano-electroplating ultrafast laser intensification and in-situ online monitoring device

An ultrafast laser and monitoring device technology, applied in measuring devices, color/spectral characteristic measurement, electrolytic components, etc., can solve problems such as in-situ online monitoring of laser plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the above technical solutions, the above technical solutions will be described in detail below with reference to the accompanying drawings and specific embodiments.

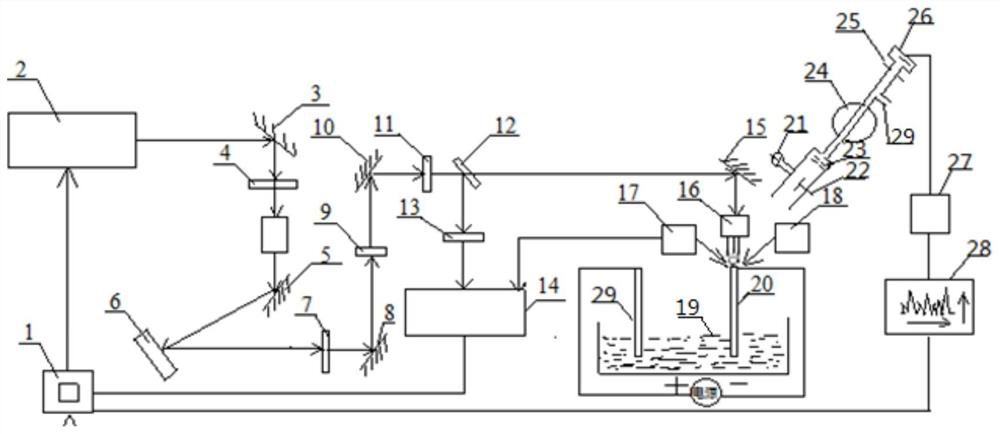

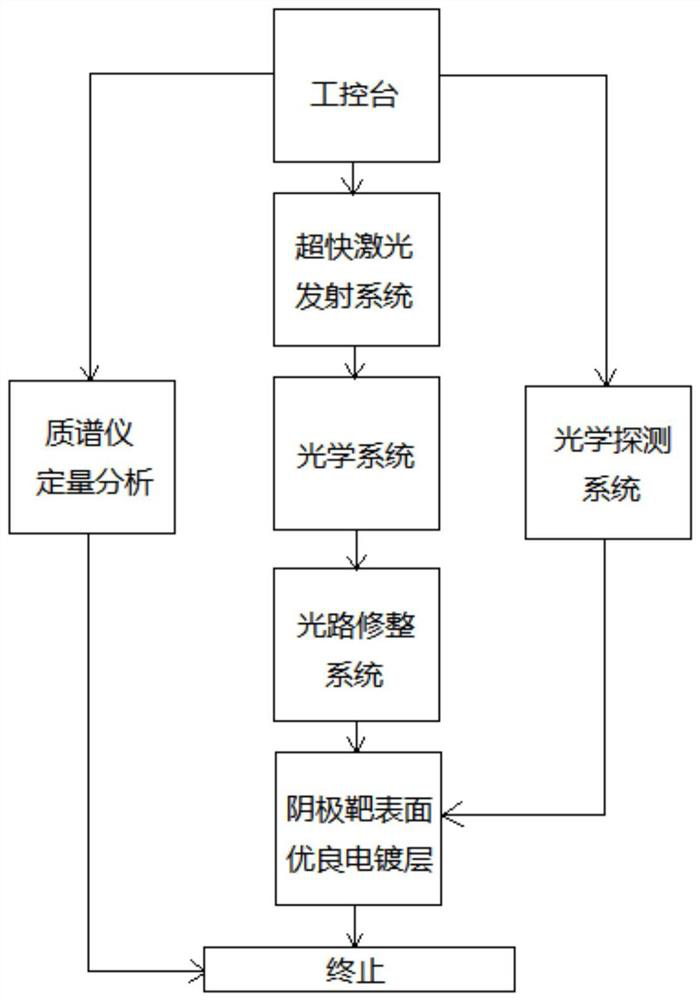

[0029] This embodiment provides a nano-electroplating ultrafast laser enhancement and in-situ online monitoring device, see figure 1 , figure 2 , mainly including: industrial console 1, ultrafast laser 2, spectrometer 14, laser probe 16, holographic camera 17, pulse generator 18, mass spectrometer and optical path system.

[0030] The pulse electroplating power supply is respectively connected with the anode 29 and the micro-nano device cathode target 20 placed in the electroplating pool 19, and the micro-nano device cathode target 20 is the object of nano-electroplating processing; the laser probe 16, the holographic camera 17 and The pulse generators 18 are all arranged in the vicinity of the cathode target 20 of the micro-nano device. The industrial computer 1 is respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com