Optical fiber microsensor and detection system for in situ determination of biofilm density distribution

A density distribution and detection system technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as inability to accurately reflect complex changes in internal structures, and achieve the effects of small system errors, high resolution, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with specific examples.

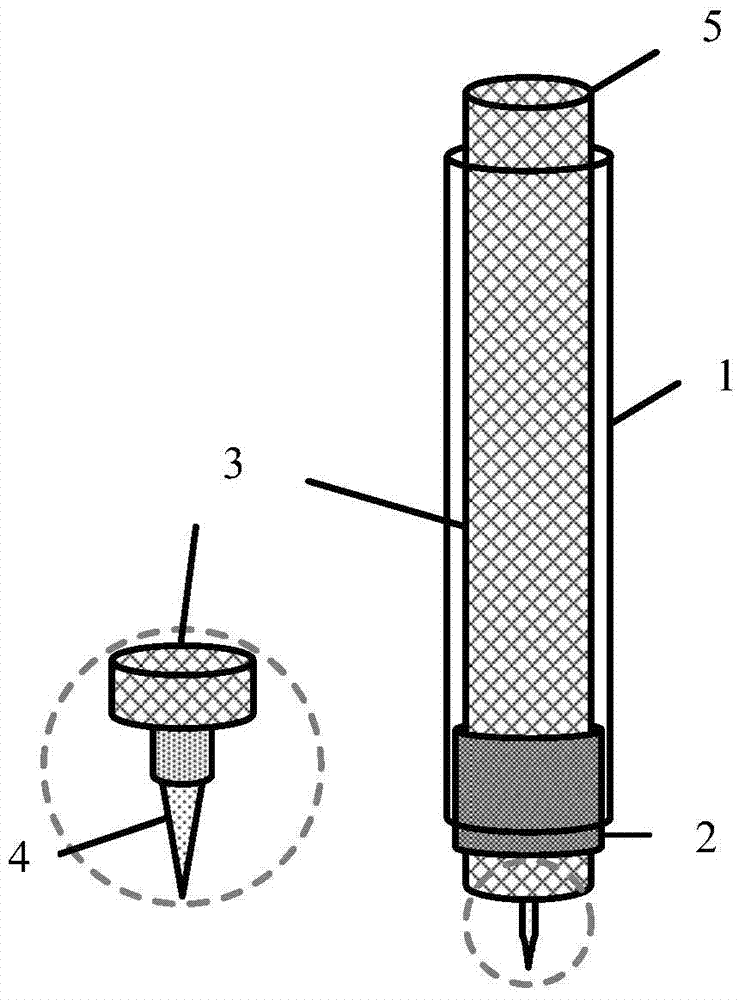

[0018] like figure 1 As shown, an optical fiber microsensor for in situ determination of biofilm density distribution, including a glass sleeve 1, a metal ferrule 2 and a single-mode optical fiber 5;

[0019] The fiber resin coating 3 at the front end of the single mode fiber 5 has been stripped, exposing the glass core tip 4 about 1 mm long. A metal ferrule 2 is sheathed 1 cm above the fiber tip, and the single-mode optical fiber 5 is fixed in the glass sleeve 1 through the metal ferrule 2 .

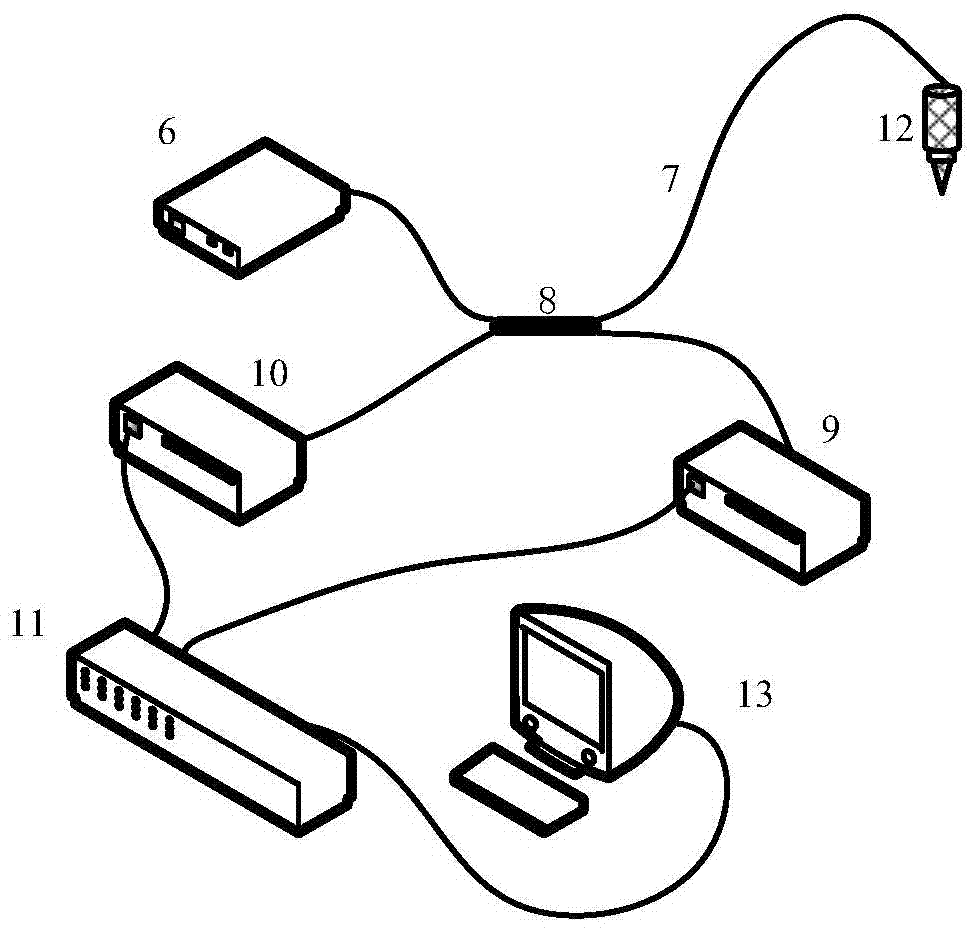

[0020] like figure 2 As shown, a detection system for measuring biofilm density distribution in situ, including light source 6, transmission fiber 7, fiber optic coupler 8, incident signal detector 9 and backscattered signal detector 10, signal amplifier 11, fiber optic microsensor 12 and computer 13 .

[0021] The light source 6 is connected to a port on one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com