Improved track structure and construction method thereof

A construction method and an improved technology, which is applied in the field of rail transit, can solve the problems that the transformation effect cannot be fully satisfied, corrode the pre-buried pipelines of the line, and reduce the insulation resistance value, etc., to solve the problem of line stray current protection, transformation difficulty and cost reduction , high insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

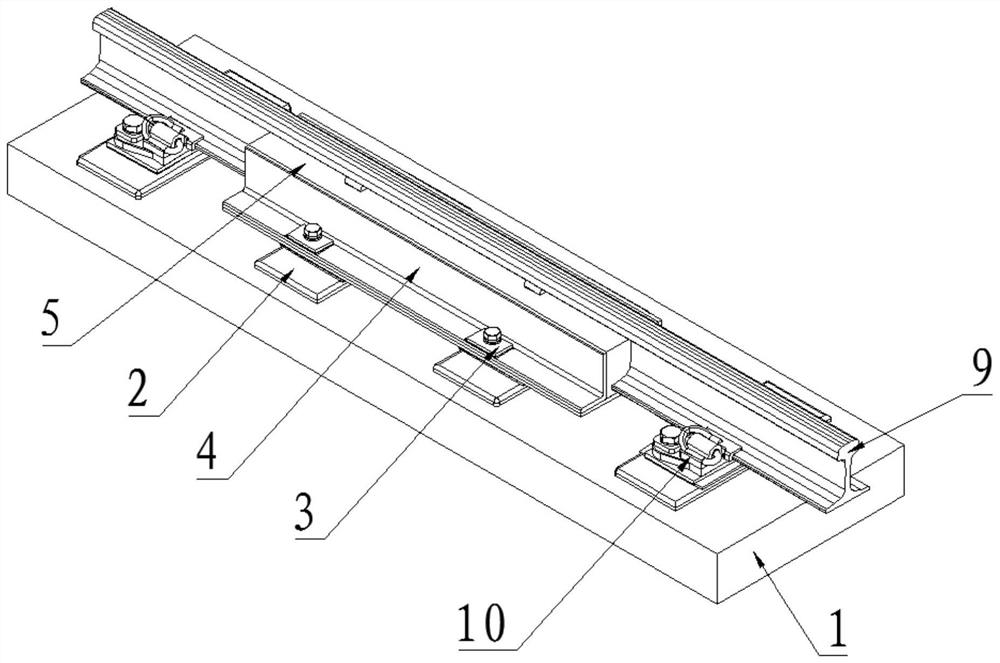

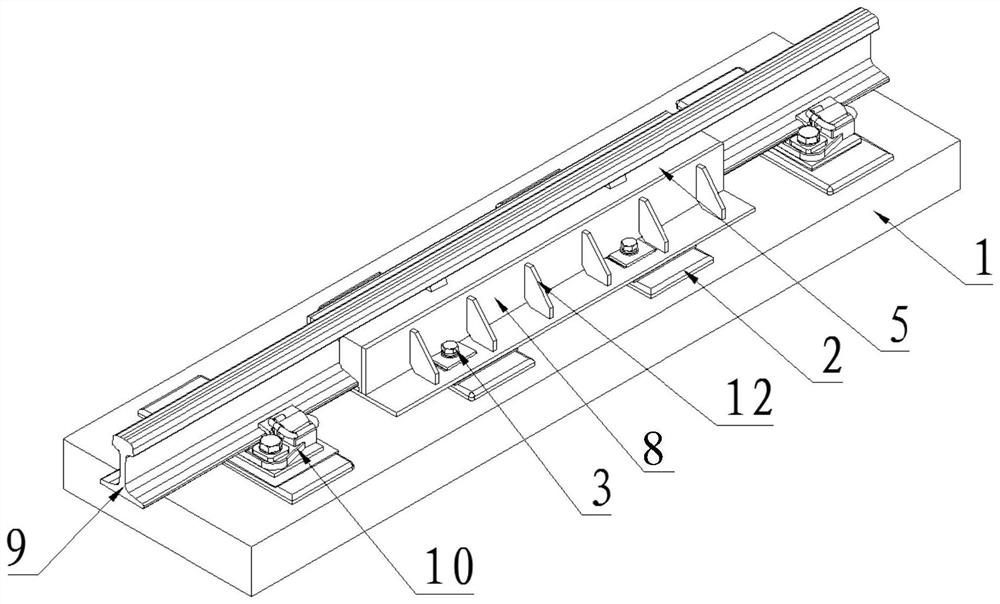

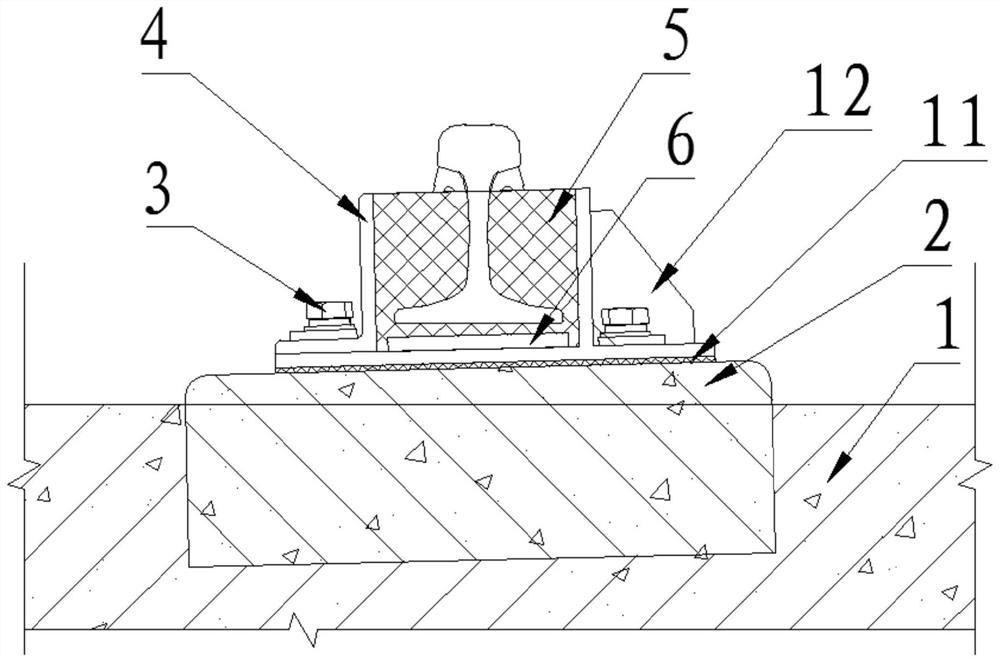

[0059] For the existing track line, it includes the existing concrete track bed 1 and the steel rail 9 laid on the concrete track bed. When the concrete track bed 1 is actually used, it can adopt a sleeper structure or a sleeperless 2 structure. In this embodiment Among them, in order to adopt the sleeper structure, in order to realize the installation and fastening of the rail 9, several sleeper bolt holes are arranged on both sides of the rail 9, and each of the sleeper bolt holes is respectively arranged on the corresponding sleeper 2, and at the same time, each The bolt holes of the sleeper correspond to the fasteners 10 for fastening the rail 9, and the fasteners 10 are equipped with iron gaskets. Under the action of the fasteners 10 and the gaskets, the bottom of the rail 9 is pressed and fastened by the fasteners 10. .

[0060] In this embodiment, an improved track structure is specifically disclosed. This track structure needs to modify the existing track structure to ...

Embodiment 2

[0071] The present invention also provides a construction method for an improved track structure. The construction method is based on the improved track structure in the above-mentioned embodiment 1. The construction method is to pour the damping material in the groove on the spot as a whole, and each section is reconstructed. The task is divided into two skylight periods. Here, the skylight period refers to the idle period of the train running line. During the skylight period, line reconstruction can be carried out, which includes:

[0072] in the first skylight period

[0073] S1: Remove the existing fasteners 10 and the iron backing plates matching the fasteners 10 at intervals; specifically: remove the existing bolts 3, spring bars, iron backing plates, etc. of the line. The removal range of the fastener 10 is to dismantle 2 every 2 or 4 every 2 or other combined dismantling methods, so as to realize pouring at intervals, and there is no limit here, so as to ensure that th...

Embodiment 3

[0082] The present invention also provides a construction method for an improved track structure, which is based on the above-mentioned improved track structure. The construction method generally prefabricates the structure in the groove in the workshop and assembles it on site , and then the rail 9 is welded, and each section of the transformation task is completed within a skylight period, and the post-casting section construction between the first section and the second section is carried out after the third section of the transformation is completed or all the transformations are completed. Specifically, the construction method includes:

[0083] T1: workshop prefabricated tank structure

[0084] a. Measure the linear state of the rail 9 in advance, assemble and fix the rail bearing groove at the place that meets the prefabricated production and maintenance requirements of the structure in the groove, and put the assembled rail bearing groove for use. This process does not n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com