Construction method for cutting and crossing existing vertical shaft through multi-cavern underground excavation channel

A construction method and shaft technology, which are applied to shaft equipment, well sinking, tunnels, etc., to achieve the effect of improving construction efficiency, shortening construction period, and ensuring structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] This embodiment also provides a construction method in which the multi-chamber underground excavation channel is cut through the existing shaft, such as Figure 1 to Figure 9 As shown, the method includes the following steps:

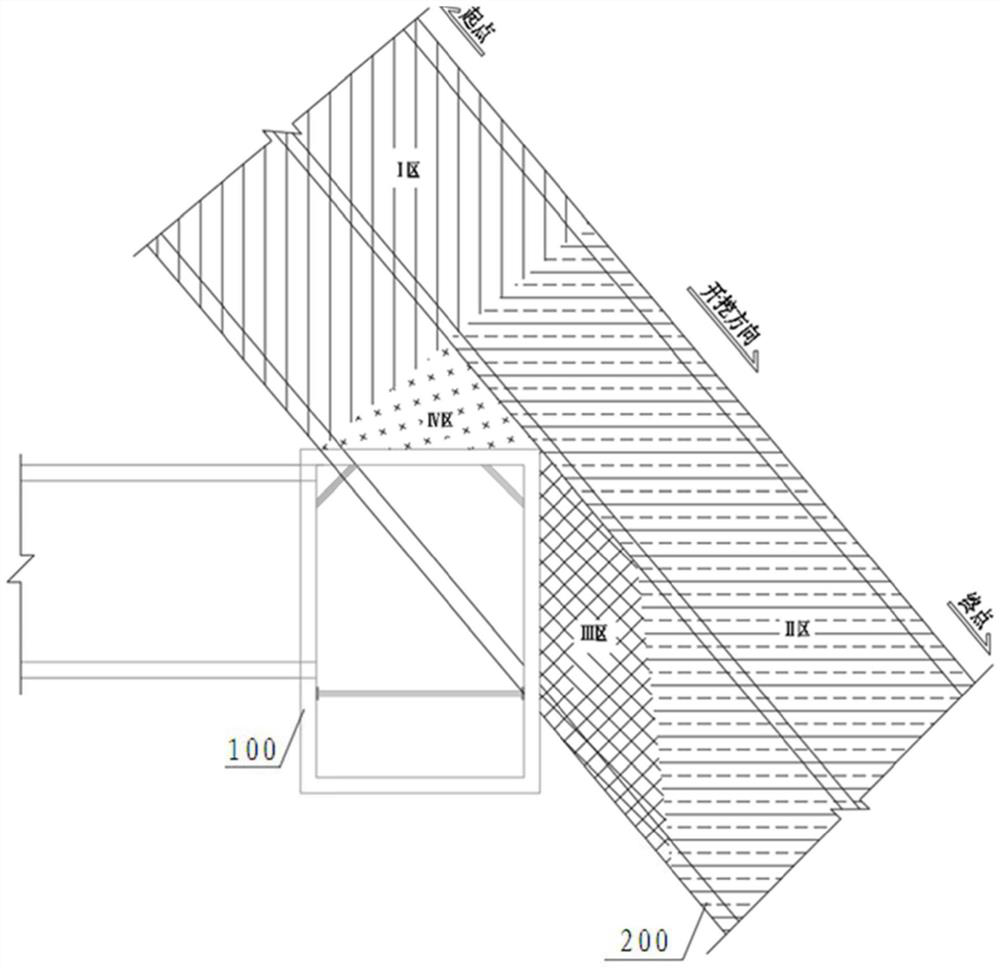

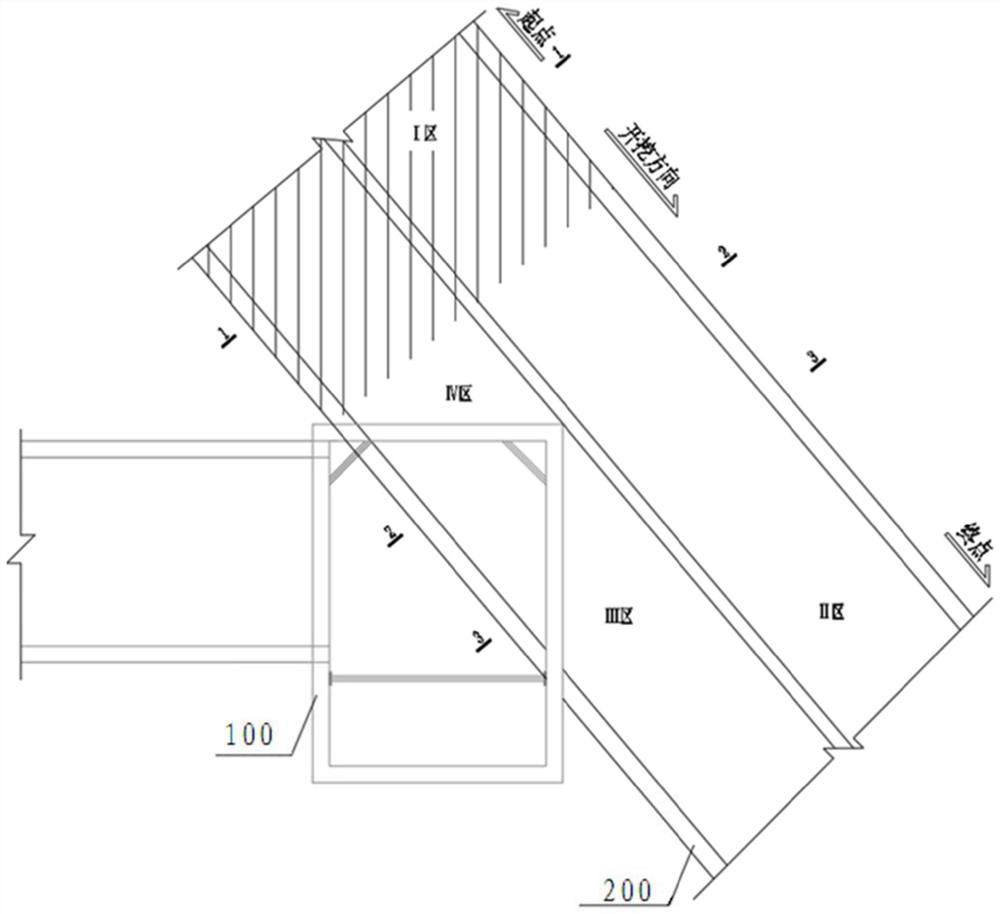

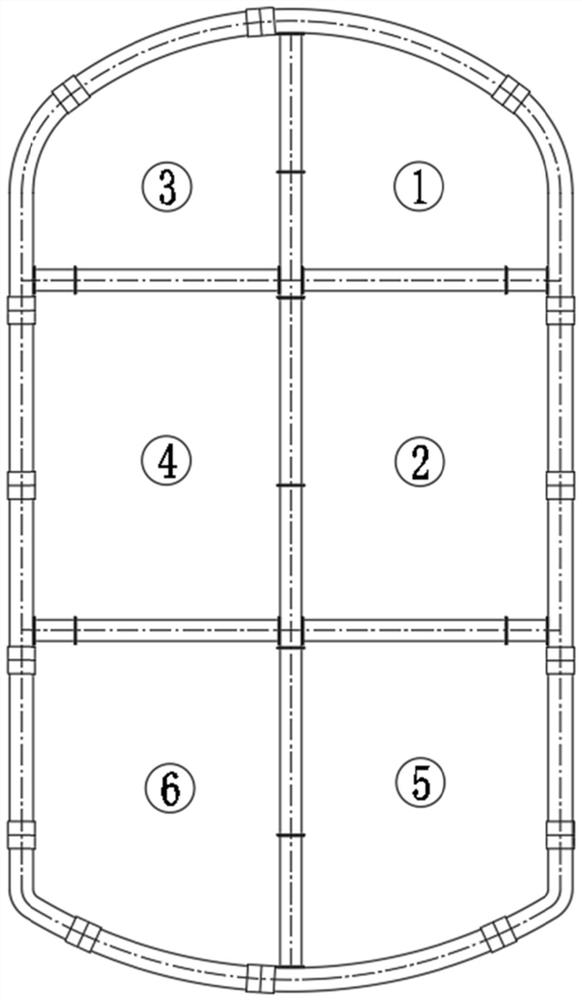

[0031] Step S1: First excavate the unaffected area (i.e. zone I) located in front of the existing shaft 100 to the skin of the existing shaft 100, temporarily close the tunnel face, and suspend excavation after the tunnel face is closed, such as figure 2 As shown; the excavation of multi-cavity submerged cross passage 200 adopts the CRD construction method, and the cross section of the cross passage is divided into six parts, arranged in three layers, left and right, and two columns. image 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com