Mounting device of all-in-one machine for road, and using method and networking mounting method thereof

A technology of installing a device and an all-in-one machine, which is applied in the directions of measuring devices, utilization of re-radiation, reflection/re-radiation of radio waves, etc., can solve the problems of difficulty in debugging accurate in place, waste of energy and time, etc., to save interaction time and time. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

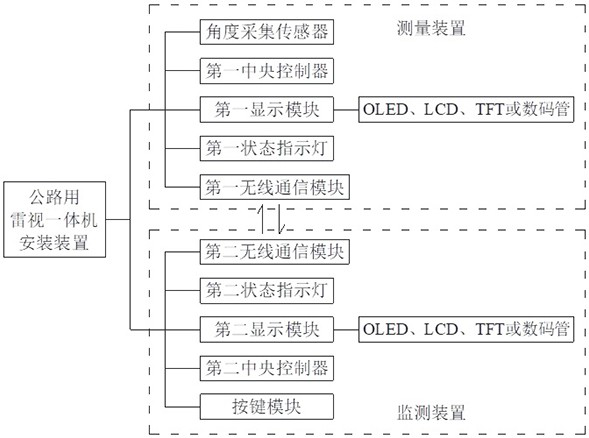

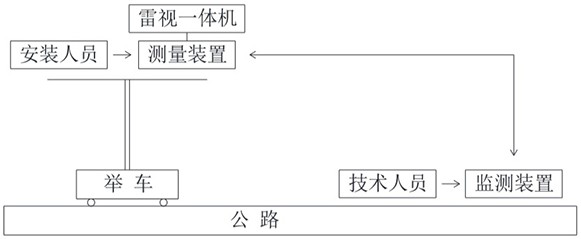

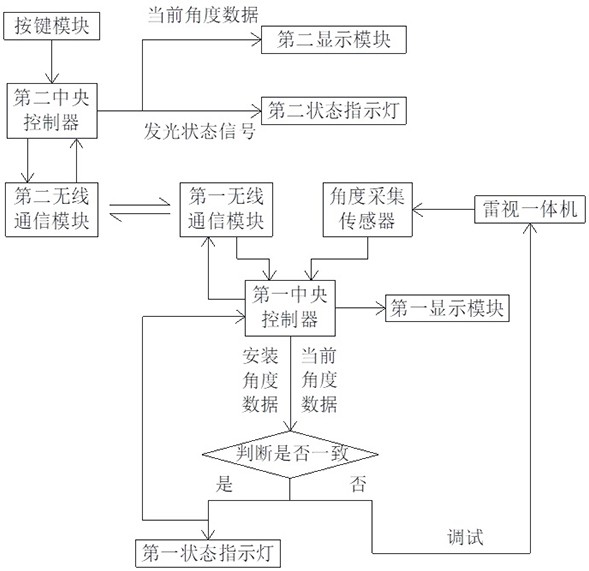

[0069] Please refer to figure 1 and figure 2 , the present embodiment provides an installation device for a LeTV all-in-one machine for road use, including a measurement device 3 installed on the LeVideo all-in-one machine 1 and a monitoring device located on the ground. The measurement device 3 includes a first central controller, an angle acquisition sensor 2, A first status indicator light, a first wireless communication module and a first display module, the monitoring device includes a second central controller, a button module, a second status indicator light, a second wireless communication module and a second display module, an angle acquisition sensor, The first status indicator light, the first wireless communication module and the first display module are respectively electrically connected to the first central controller, and the button module, the second status indicator light, the second wireless communication module and the second display module are respectivel...

Embodiment 2

[0081] This embodiment is substantially the same as Embodiment 1, the difference lies in the setting of the measuring device 3 .

[0082] Please refer to Figure 9 and Figure 10 , the measuring device 3 has a housing 31, which is in the shape of a cuboid as a whole, and at least one suction cup 32 is attached to the side of the housing 31. This embodiment adopts two suction cups 32, which are distributed up and down. The suction cups 32 are used for adsorption on Levision On the panel surface of the all-in-one machine 1, the angle acquisition sensor 2 is placed in the housing 31, and the PCB board in this embodiment is fixed in the measuring device 3 by screws, and the angle acquisition sensor 2 is inserted into the PCB board and perpendicular to the The panel of the All-in-one machine 1 facing the area to be measured; the measuring device 3 is connected to the surface of the All-in-one machine 1 by suction cup 32, so that the installer can accurately and quickly fix the mea...

Embodiment 3

[0084] This embodiment is roughly the same as Embodiment 1, the difference lies in the setting of the measuring device 3 and the monitoring device, wherein the measuring device 3 and the monitoring device respectively have a watchdog module, a charging module and a power supply module, the first status indicator light and the second The number of the two state indicator lights is different, and the installation angle of the angle acquisition sensor 2 is also different, and so on.

[0085] Please refer to Figure 11 , this embodiment provides an installation device for a LeTV all-in-one machine for road use, including a measuring device 3 installed on the All-in-one machine 1 and a monitoring device located on the ground. The measuring device 3 is convenient for the installer to determine the angle of the all-in-one machine 1 and For debugging, the monitoring device is convenient for technicians to guide the installer and supervise the installer to install the LeTV all-in-one m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com