Pollution source searching method based on defective products in semiconductor production line

A semiconductor and production line technology, applied in the field of pollution source search, to achieve the effect of extreme efficiency, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

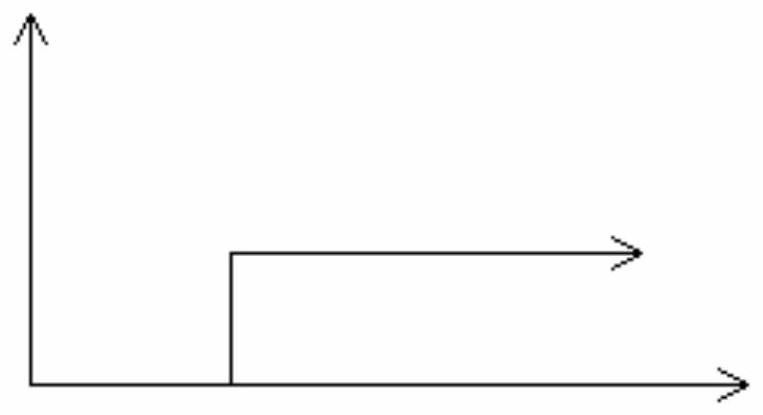

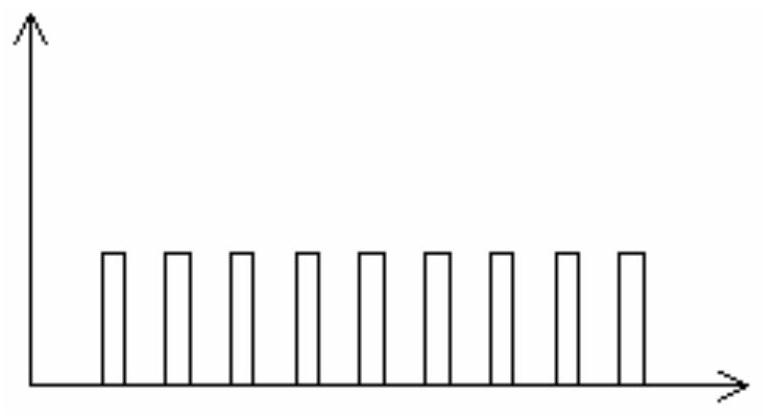

[0055] see Figure 1~5 As shown, a method for finding pollution sources based on defective products in a semiconductor production line. The semiconductor production line is located in a clean room to be monitored. The semiconductor production line includes 1200 procedures, and every 2 to 5 procedures are used to conduct a good inspection of semiconductor products. Rate detection; including the following steps:

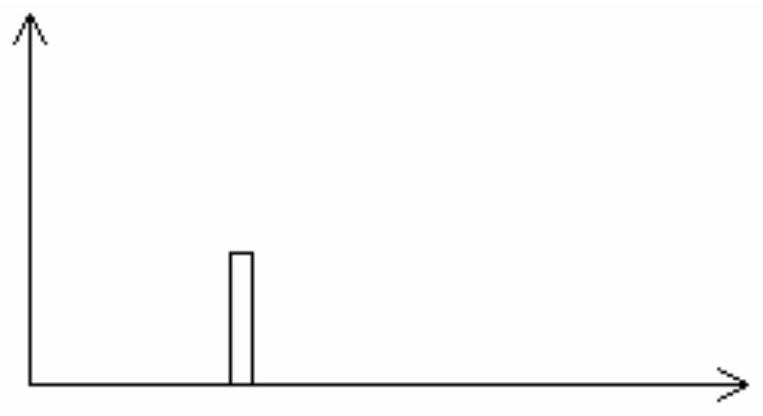

[0056] (1) When a defect in a semiconductor product is detected in a certain yield inspection process, first determine whether the cause of the defect is caused by the machine associated with the defective product or the environment. If the former is the case, the machine will be repaired. If the latter, proceed to the next step;

[0057] In this embodiment, the order of the first 10 processes and the yield detection process is as follows: P1-P2-T1-P3-P4-P5-T2-P6-P7-P8-P9-P10-T3, wherein, P1 to P10 are respectively Refers to the 1st to 10th process of semiconductor p...

Embodiment 2

[0072] A method for finding pollution sources based on defective products in a semiconductor production line, the steps of which are the same as in Embodiment 1, the only difference being that in step (7), a movable sampling device is used to separate the sources of pollutants after the previous steps are eliminated Further sampling, followed by further testing, can determine the source of the contaminant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com