Charging topology network and direct current contactor control system and method in charging system

A DC contactor, topology network technology, applied in the direction of collectors, battery circuit devices, instruments, etc., can solve the problem of unstable charging, and achieve the effect of improving operation stability and operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

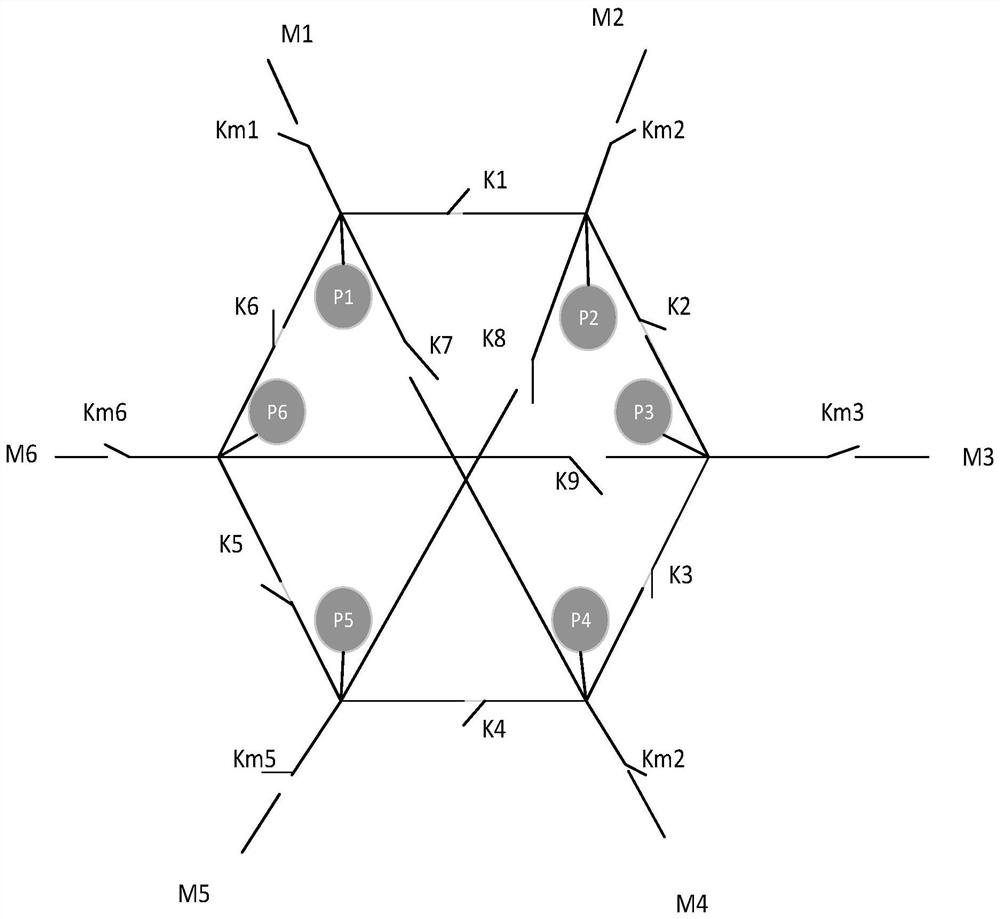

[0045] like figure 1 As shown, the charging topology network in the present invention includes: multiple sets of power modules, multiple sets of DC contactors and multiple sets of terminals;

[0046] Multiple sets of DC contactors include: multiple sets of first DC contactors K1, K2, K3, K4, K5, K6; multiple sets of second DC contactors K7, K8, K9 and multiple sets of main DC contactors Km1, Km2, Km3, Km4, Km5, Km6;

[0047] Multiple groups of power modules include power modules P1, P2, P3, P4, P5, and P6; first DC contactors K1, K2, K3, K4, K5, and K6 are connected in series to form a ring structure; power modules P1, P2, P3, and P4 , P5 and P6 are respectively connected to corresponding terminals M1, M2, M3, M4, M5 and M6 through a group of main DC contactors Km1, Km2, Km3, Km4, Km5 and Km6;

[0048] Each group of power modules is electrically connected to the main DC contactor connected to any group of non-adjacent power modules on the ring structure through a group of se...

Embodiment 2

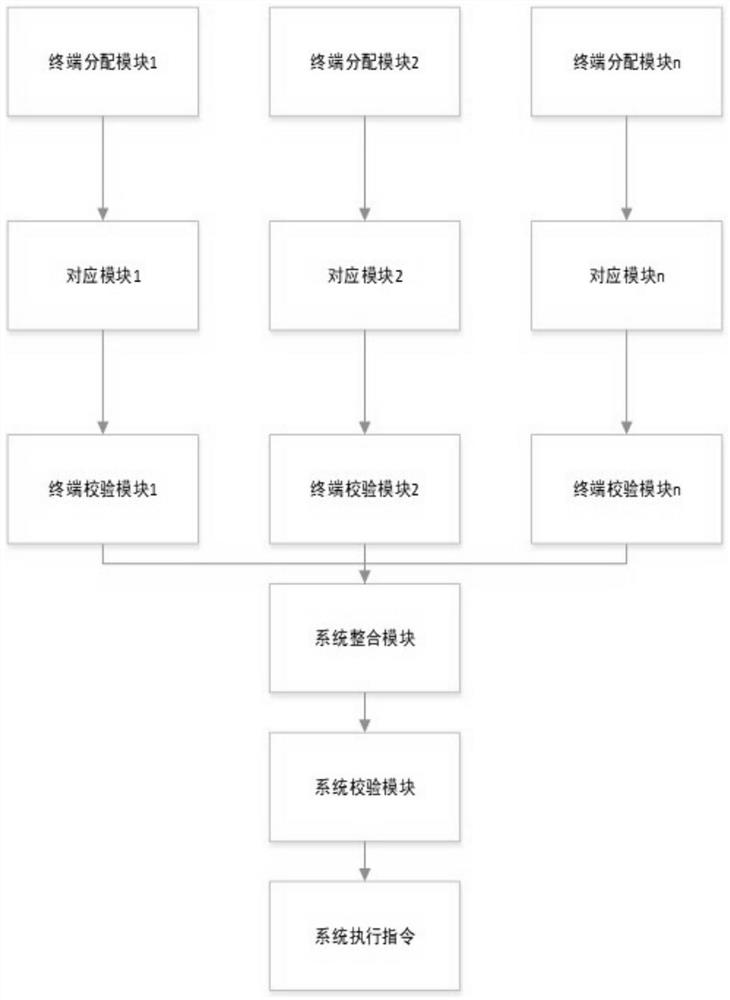

[0055] see figure 2 As shown, a DC contactor control system in a charging system includes: the charging topology network and a controller described in Embodiment 1; the controller includes:

[0056] Terminal allocation module: according to the power required by each terminal, allocate appropriate power modules;

[0057] Corresponding module: according to the allocated power module, obtain the closing status of the DC contactors K1-K9 under the corresponding power module;

[0058] Terminal verification module: verify the data obtained by the corresponding module according to the verification principle of each terminal, and obtain the closing status of the contactor of the terminal;

[0059] System integration module: Integrate the closing conditions of the contactors of all terminals to obtain the closing conditions of the DC contactors K1-K9 under each terminal;

[0060] System verification module: According to the system verification principle, the data obtained by the sys...

Embodiment 3

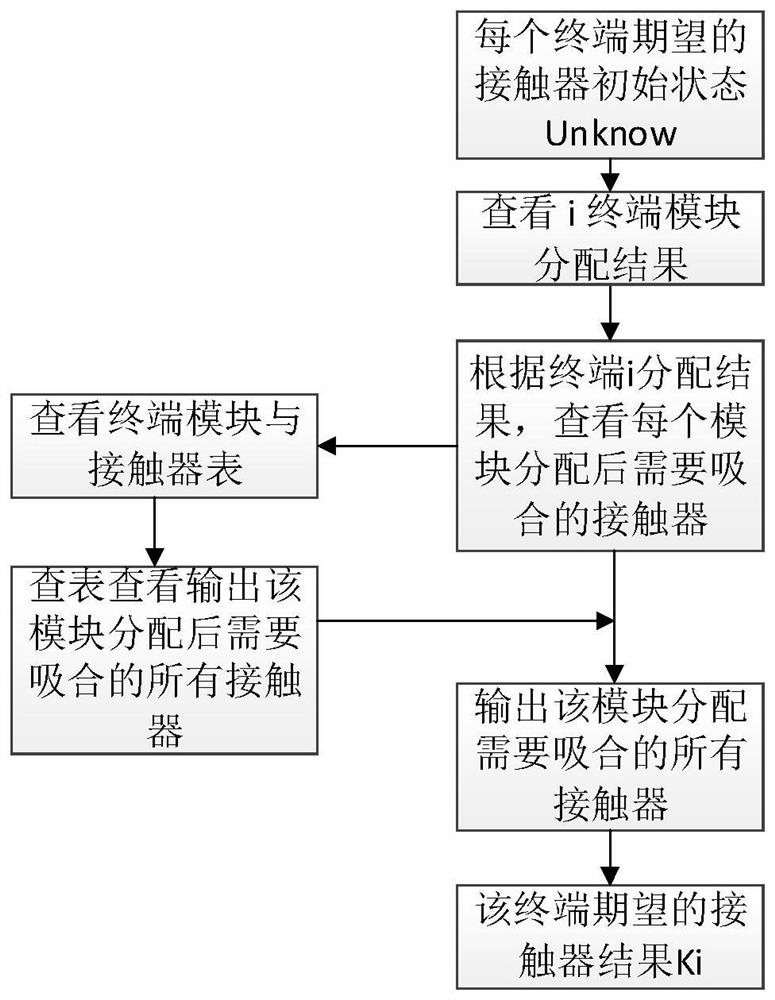

[0062] see image 3 As shown, the present invention provides a control method for a DC contactor control system in a charging system, comprising the following steps:

[0063] Obtain the power module allocation results of each terminal;

[0064] According to the allocated power modules, the closing expectation of the DC contactor corresponding to each power module is obtained;

[0065] According to the principle of terminal verification, judge the closure of each power module of the terminal and the DC contactor, and obtain the expected result of the terminal;

[0066] Integrate the expected results of each terminal to obtain the expected results of the system;

[0067] According to the principle of system verification, the expected result of the system is judged, and the final execution result of the system is obtained.

[0068] In the present invention, the terminal verification principle means that the same contactor that has a pull-in expectation under the terminal can o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com