Cable robot for coating procedures

A robot and cable technology, applied in the direction of program-controlled manipulators, manipulators, spraying devices with movable outlets, etc., can solve problems such as cable breakage, device drop, anchor point overload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

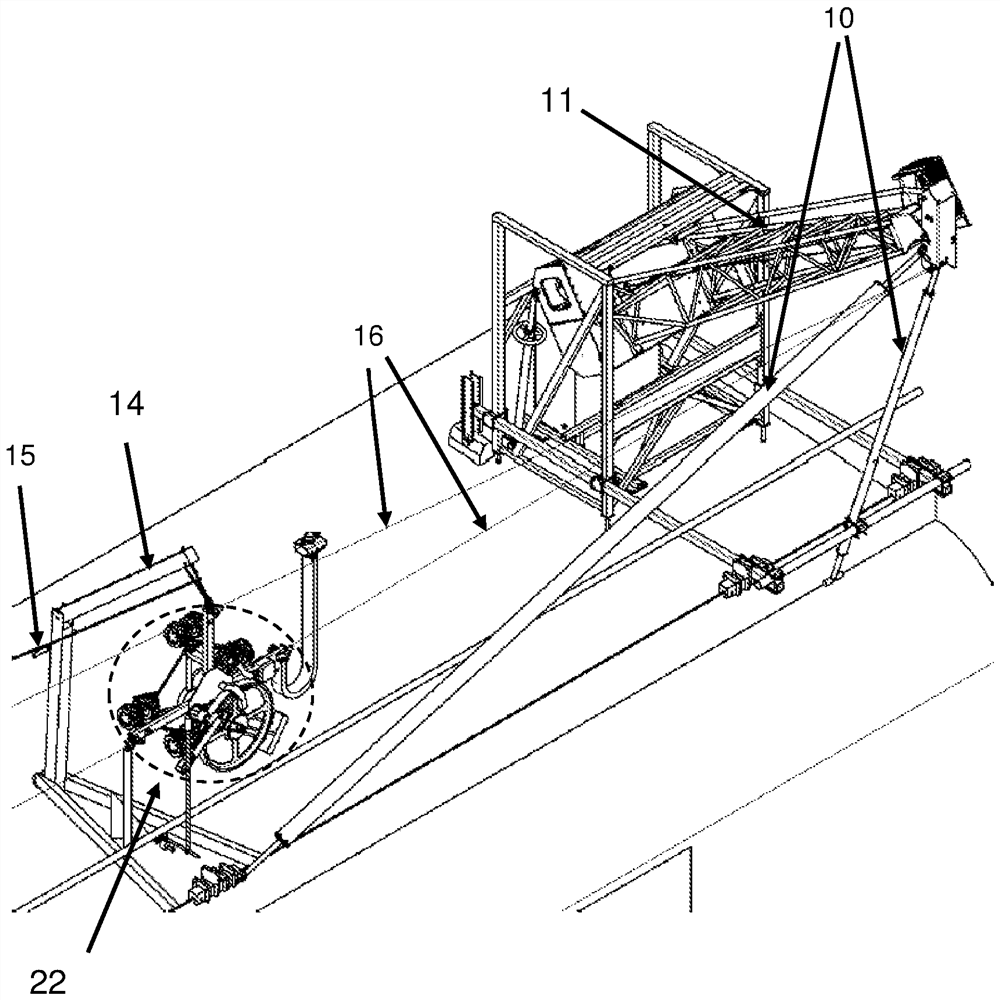

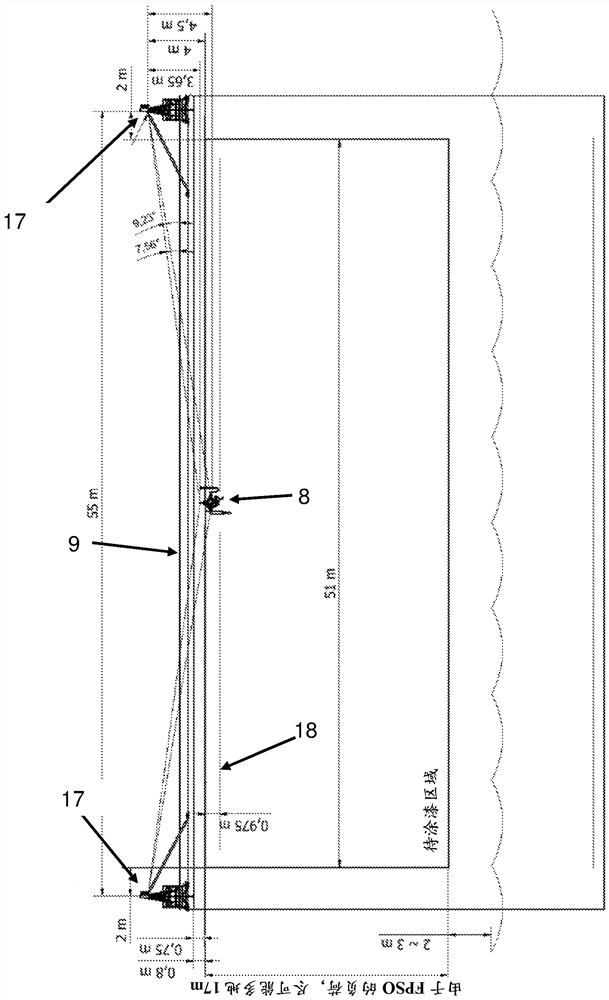

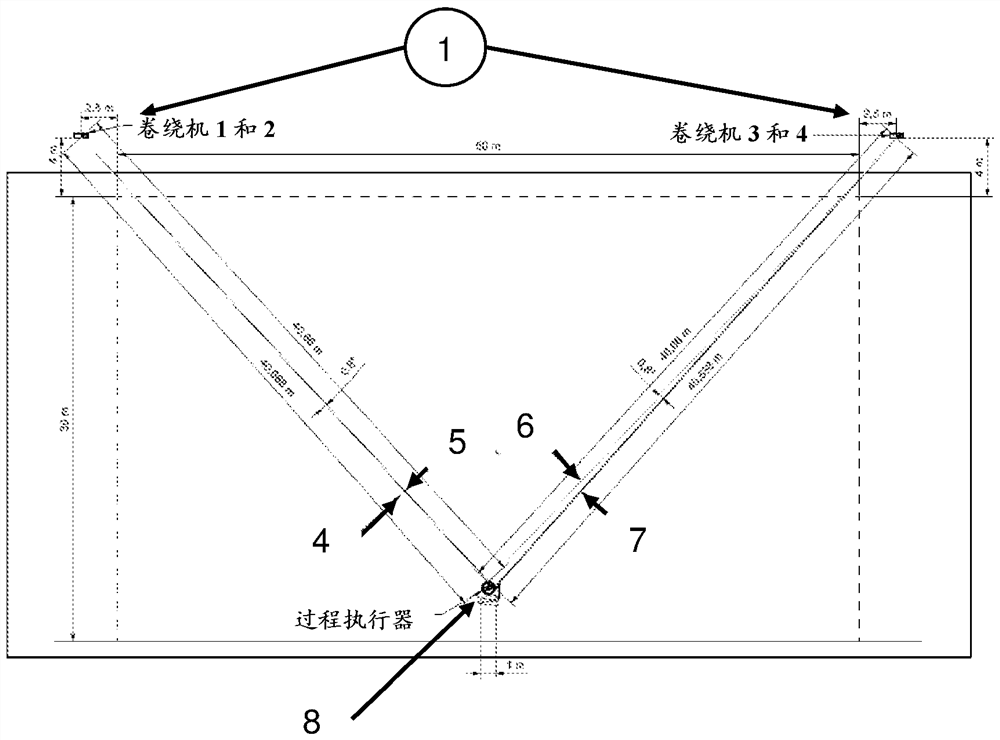

[0034] The purpose of the present invention is to use a cable construction to suspend a mobile platform developed to couple the oscillating mechanism that performs the painting process and also move quickly and precisely to ensure the quality of the painting on the hull of the ship, but Not limited to this application.

[0035] For a better understanding of the invention, we shall illustrate it by means of the following description, which is a preferred embodiment of the invention. However, it will be apparent to those skilled in the art that the present invention is not limited to this particular embodiment.

[0036] The present invention relates to the arrangement of cables for suspending a mobile platform (3), novel because the platform is positioned by four cables, where its suspension system is placed on a free "Mecanum" wheel that behaves like a sphere (21) on. In this case it has two fixed pivots at deck level and four moving pivots at the ends of the mobile platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com