Machining and positioning process method for casting high-temperature alloy ring block parts

A technology of high-temperature alloys and process methods, which is applied in the field of aero-engines, can solve problems such as large tool consumption, poor processing positioning stability, and low processing efficiency, and achieve the effects of improving processing efficiency, concentrating processes, and increasing the number of clamping parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] At present, among the models of engines undertaken by the company, there are many cast high-temperature alloy ring parts. Due to the limitation of structure and processing characteristics, the cost of fixtures and tools is relatively high. . The processing and positioning process method of the present invention changes the original part process design idea, greatly improves the processing quality of the parts, reduces the cost of tooling, greatly concentrates the process, reduces non-value-added time such as turnover, improves processing efficiency, and saves more than half of tooling costs. Shorten the processing time by more than 20%.

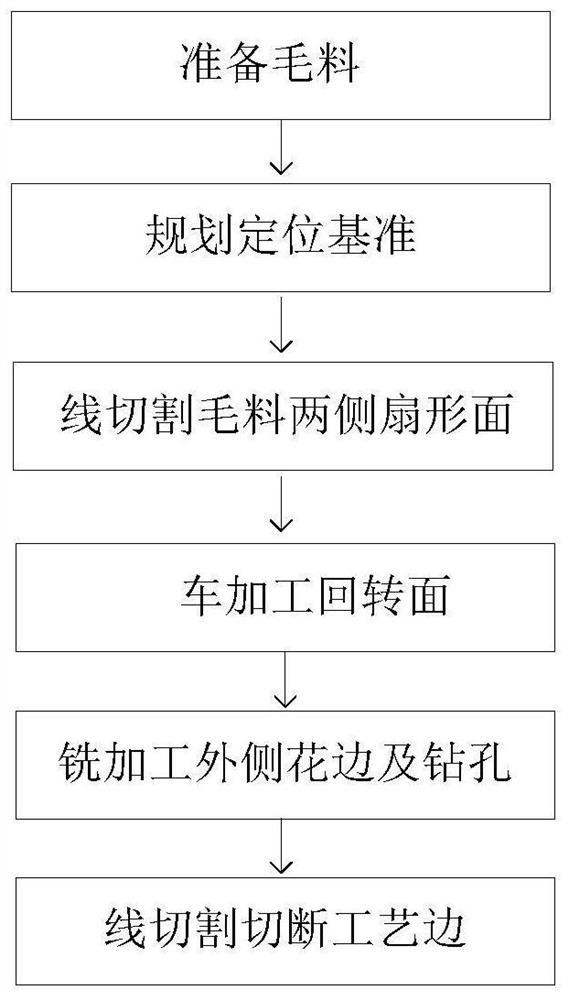

[0071] A processing and positioning process method for casting high-temperature alloy ring block parts in this embodiment includes the following steps:

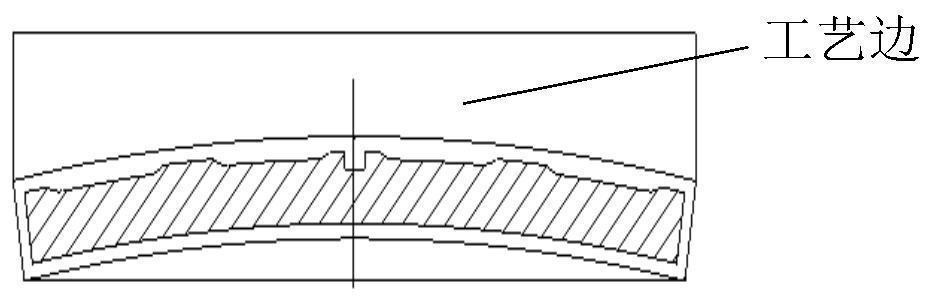

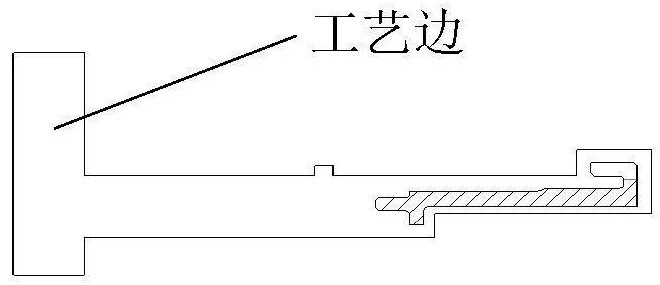

[0072] 1. Prepare the wool, which is provided with a craft edge;

[0073] 2. Milling 1 datum plane and 2 datum holes on the process side, the present invention uses the unified benc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com