Planet-like rotary type overhauling robot suitable for multi-size inhaul cables

A planetary rotation and robot technology, applied in the field of crawling robots, can solve the problems of cable damage, inconvenient cable replacement, and safety threats to cable maintenance personnel, and achieve the effect of reducing maintenance costs and avoiding secondary corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

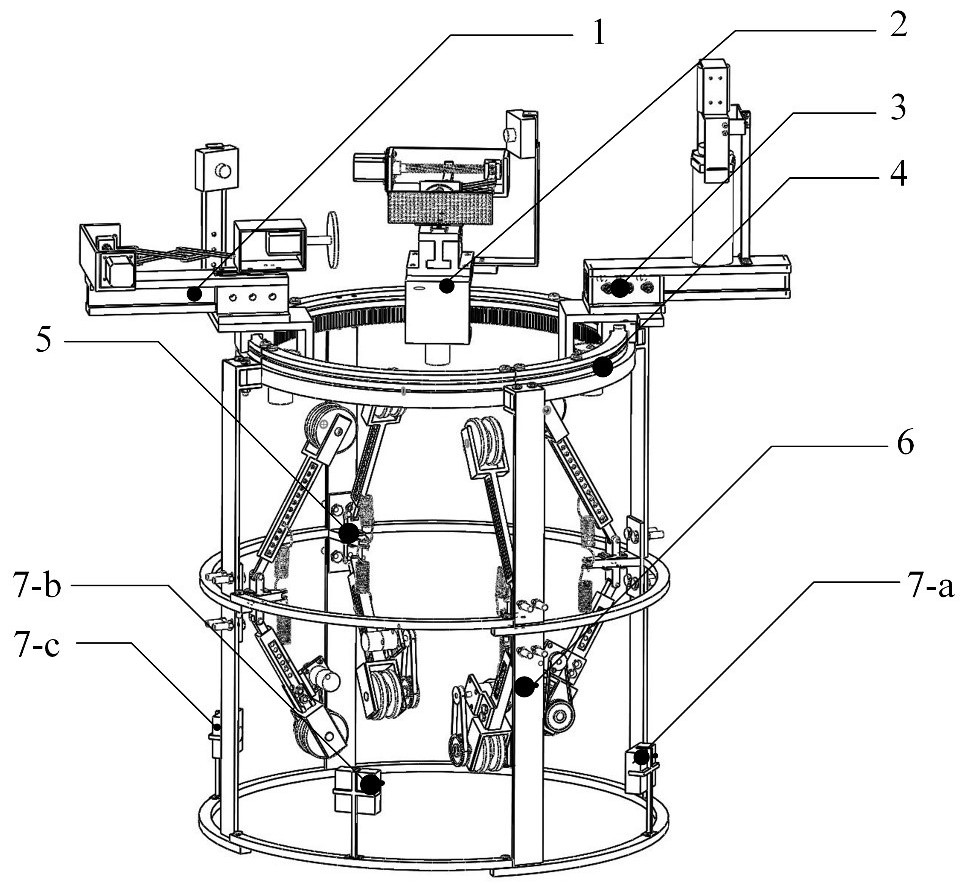

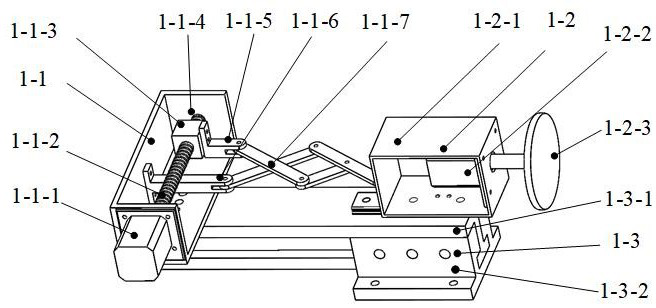

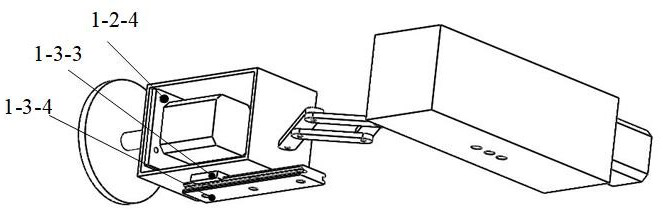

[0034] Such as Figure 1 to Figure 11 As shown, this specific embodiment adopts the following technical solutions: it includes a cable grinding device 1, a cable cleaning device 2, a cable spraying device 3, an arc-guided rotating platform 4, a pressing and climbing device 5, a robot base 6, a detection Mechanism 7, the cable grinding device 1 includes a cable grinding displacement mechanism 1-1, a cable grinding actuator 1-2, and a cable grinding fine-tuning base 1-3, and the cable grinding displacement mechanism 1-1 includes Drive motor Ⅰ 1-1-1, lead screw Ⅰ 1-1-2, lead screw base slider Ⅰ 1-1-3, lead screw support Ⅰ 1-1-4, scissors swimming joint support Ⅰ 1-1 -5. Scissor fixed connection bracket I 1-1-6, scissor structure I 1-1-7, the cable grinding actuator 1-2 includes a grinding motor base 1-2-1, a grinding motor 1- 2-2. Grinding head 1-2-3, grinding motor fixing plate 1-2-4, said cable grinding position fine-tuning base 1-3 includes upper base I 1-3-1, lower base I 1-...

Embodiment 2

[0038] According to the device described in Example 1, when the robot is installed on cables of different sizes, the grinding distance of the cable grinding mechanism 1 also needs to be adjusted accordingly, and the drive motor I 1-1-1 is directly connected to the lead screw I 1-1-2 and fixed on the lead screw bracket Ⅰ1-1-4, the drive motor Ⅰ1-1-1 drives the lead screw Ⅰ 1-1-2 to rotate, and the lead screw slider Ⅰ 1-1-3 is installed on the screw The rod Ⅰ 1-1-2 moves along its axial direction with the rotation of the lead screw Ⅰ 1-1-2, and one end of the lead screw support Ⅰ 1-1-5 is fixed on the lead screw slider Ⅰ 1-1 by screws. On -3, the other end is hinged with one side of the bilateral ends of the scissor structure I 1-1-7, and the other side of the double ends of the scissor structure I 1-1-7 is connected with one side of the scissor fixed joint bracket I 1-1-6 Side hinged, the other side of the scissors fixed joint bracket Ⅰ 1-1-6 is fixed on the lead screw bracket ...

Embodiment 3

[0041] According to the device described in Embodiment 1, when the size of the cable is different, the cleaning working distance of the cable maintenance robot also needs to be adjusted accordingly, and the driving motor II 2-1-1 is directly connected to the lead screw II 2-1 -2 and fixed on the lead screw bracket Ⅱ 2-1-4, the driving motor Ⅱ 1-1-1 drives the lead screw Ⅰ 1-1-2 to rotate, and the lead screw slider Ⅱ 2-1-3 is installed on the lead screw Ⅱ 2 -1-2 and move along its axial direction with the rotation of the screw Ⅱ 2-1-2, one end of the screw slider bracket Ⅱ 2-1-5 is fixed on the screw slider Ⅱ 2-1 On -3, the other end is hinged to one side of the bilateral ends of the scissor structure II 2-1-7, and the other side of the bilateral ends of the scissor structure II 2-1-7 is connected to the scissor fixed joint bracket II 2-1-6 One side is hinged, the scissors fix the other side of the connecting bracket II 2-1-6 and the other side is fixed on the lead screw bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com