Flat die set for producing fabricated concrete member and using method thereof

A concrete and prefabricated technology, applied in the direction of mold fixtures, mold auxiliary parts, auxiliary molding equipment, etc., can solve the problem of large floor space, and achieve the effect of saving floor space, stable sliding process, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-5 The application is described in further detail.

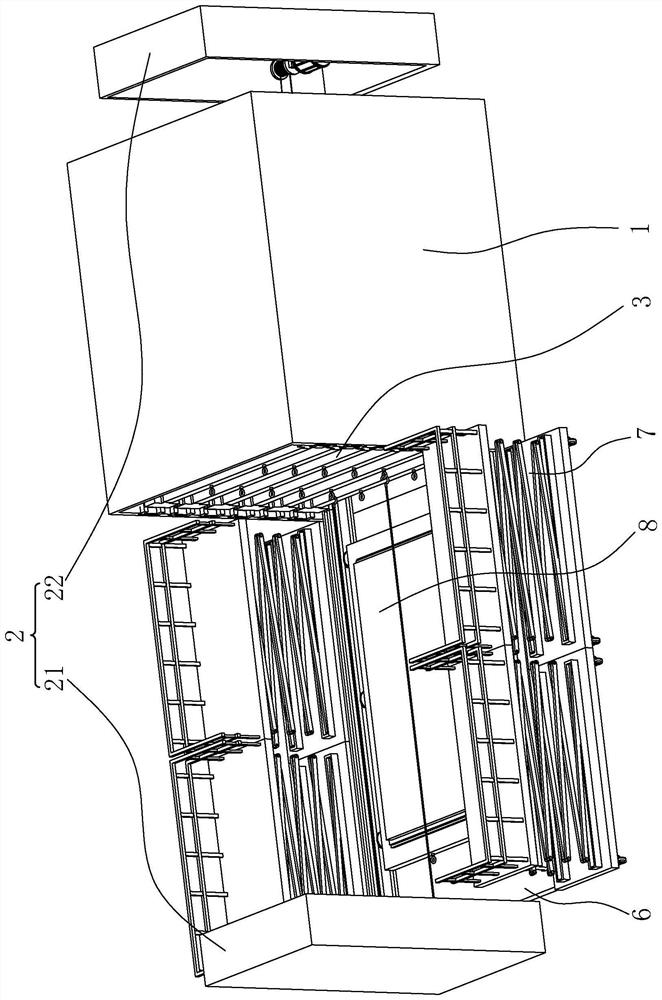

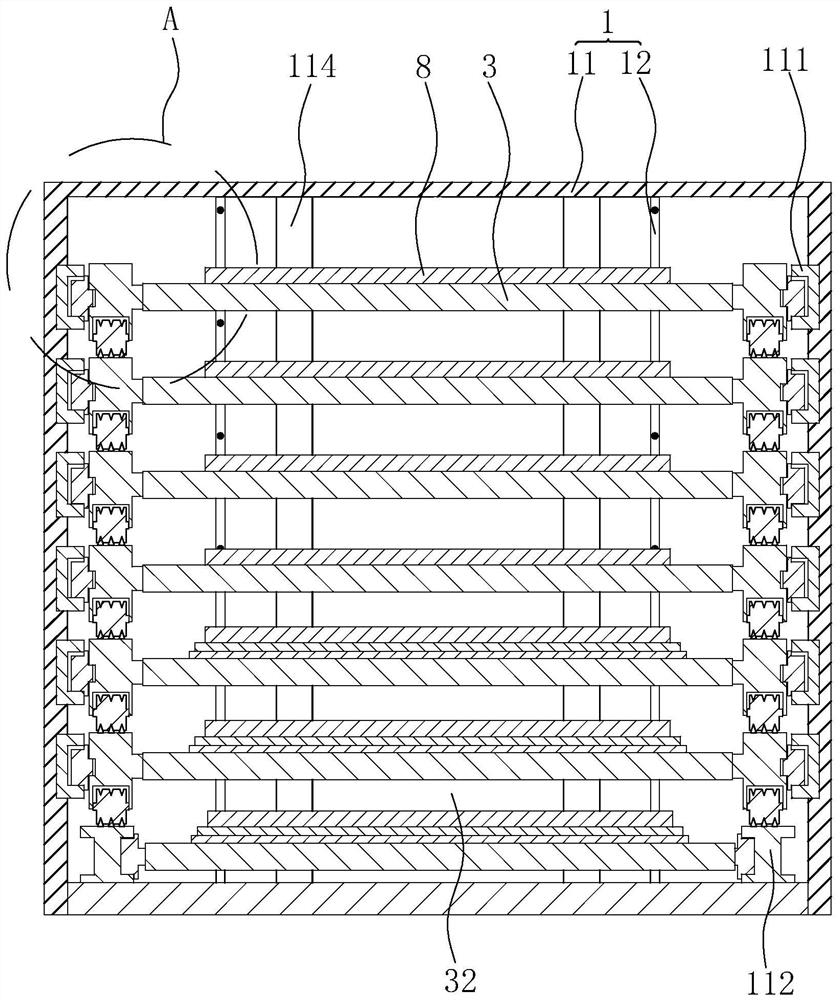

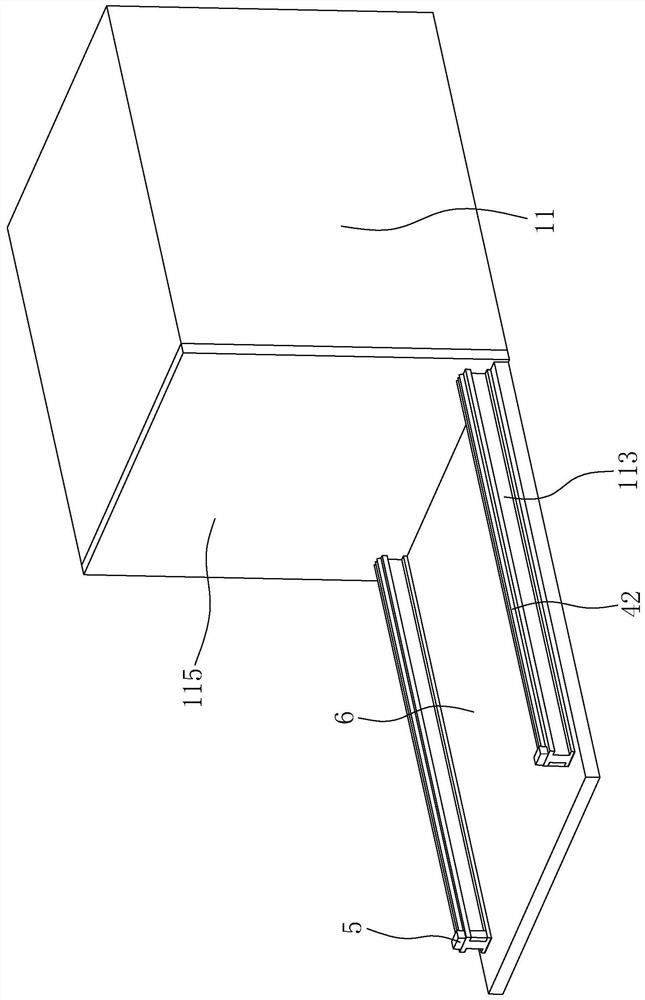

[0047] The embodiment of the present application discloses a flat formwork set for the production of a prefabricated concrete component and a method for using the same. refer to figure 1 , a flat mold group for the production of fabricated concrete components includes a curing bin 1 and a mold table 3, the mold table 3 is provided with a plurality of mold tables 3 arranged in the curing bin 1 along the vertical direction, and the plurality of mold tables 3 All are placed horizontally and are slidably connected with the curing bin 1.

[0048] When using the mold table 3 to make the concrete member 8, the mold table 3 is pulled out from the curing warehouse 1, and then mold assembly, steel bar binding and concrete pouring are performed on the mold table 3, and then the mold table 3 is pushed into the curing warehouse 1, thereby using the curing bin 1 to realize the curing of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com