Printing medium flattening device of printer and printer

A printing medium and flattening device technology, applied in printing devices, printing, etc., can solve the problems of thin paper stretching, deformation, wrinkling, etc., and achieve the effect of increasing resistance and avoiding drumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

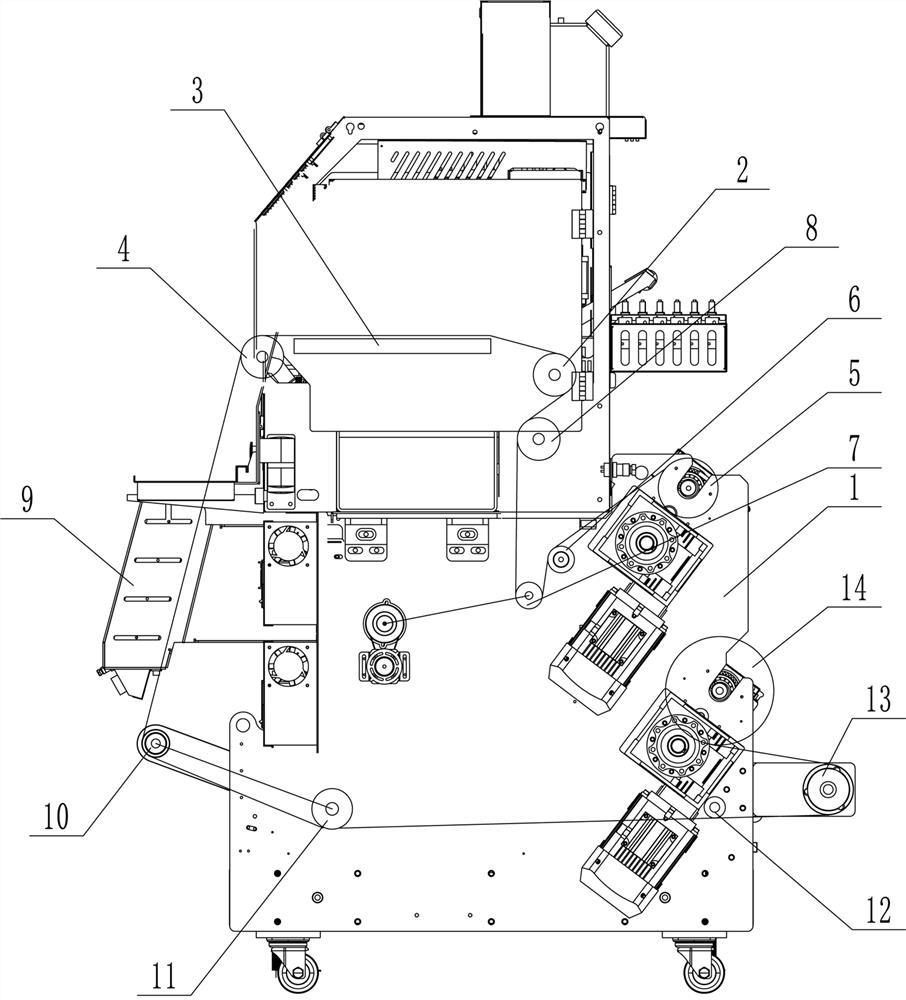

[0032] like figure 1 As shown, a printing medium flattening device of a printer includes a frame 1 and a brush roller 2 at the feeding end, a printing panel 3 and a brush roller 4 at the paper output end respectively arranged on the support 1 .

[0033] Both the brush roller 2 at the paper feeding end and the brush roller 4 at the paper outlet end include a roller body and brushes densely distributed on the surface of the roller body, and the brushes are all plastic brushes with elastic deformation capability. The brush roller 2 at the paper feeding end is arranged on the paper feeding side of the printing panel 3 , and the brush roller 4 at the paper outlet end is arranged on the paper outlet side of the printing panel 3 .

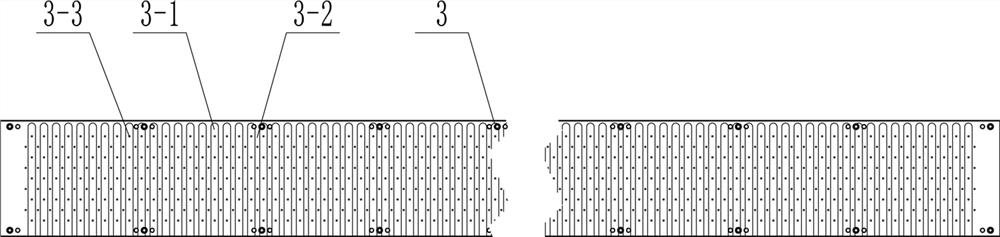

[0034] The printing panel 3 is provided with several parallel grooves 3-1, and the extending direction of the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com