Multi-line spiral conveying equivalent distribution auger for white celery hilling

A technology of equal distribution and screw conveying, which is applied in the field of agricultural machinery, can solve the problems of clogged soil distribution and unevenness, and achieve the effect of easy inspection and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

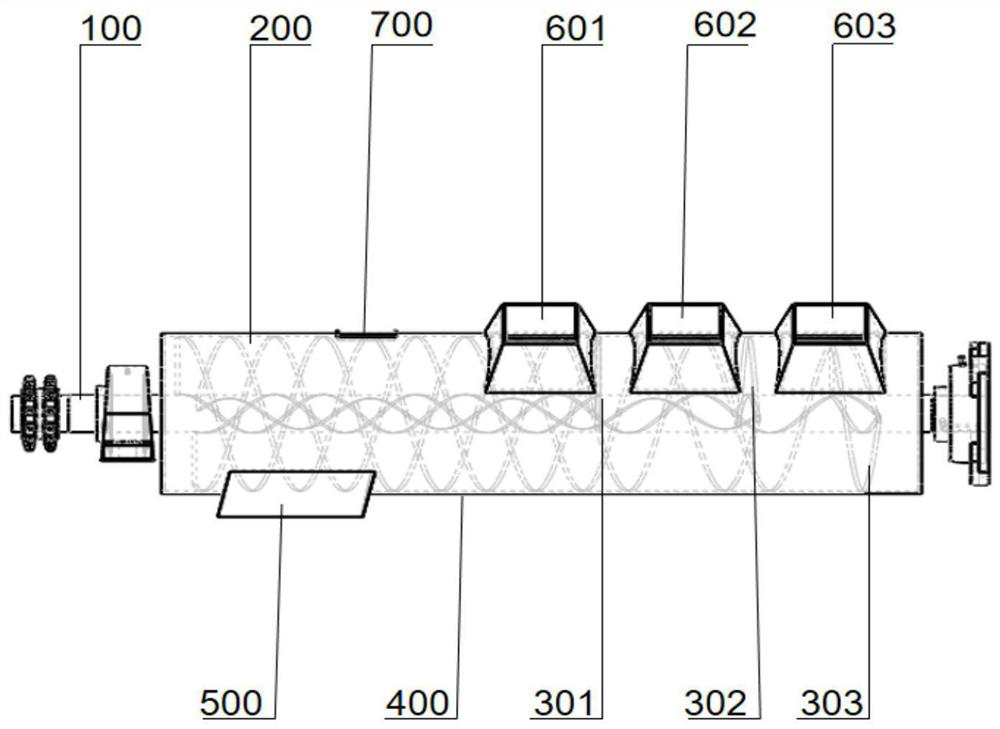

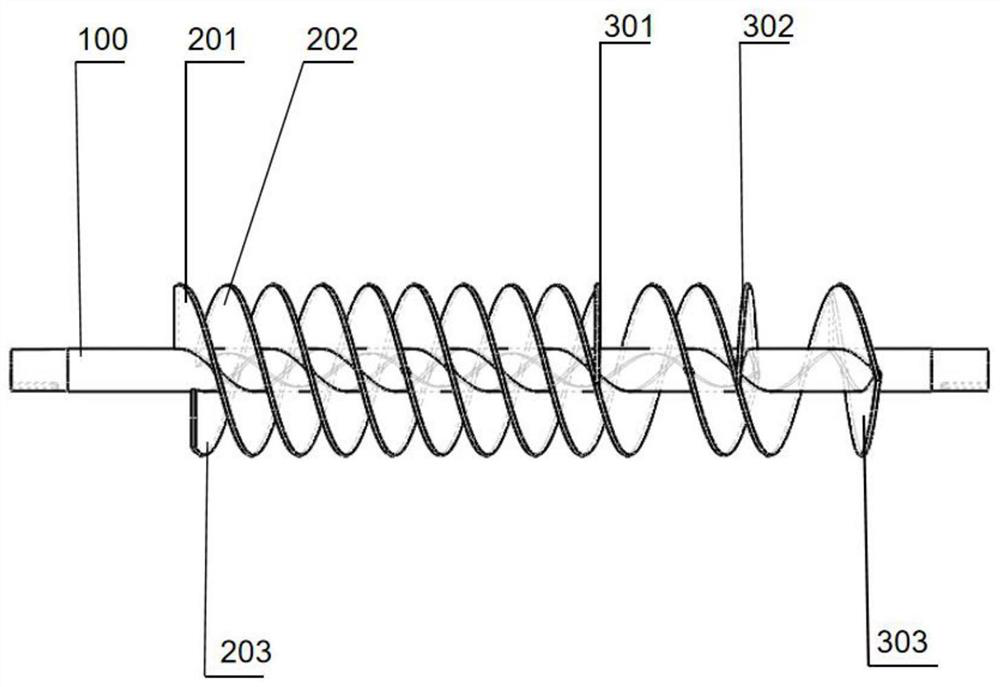

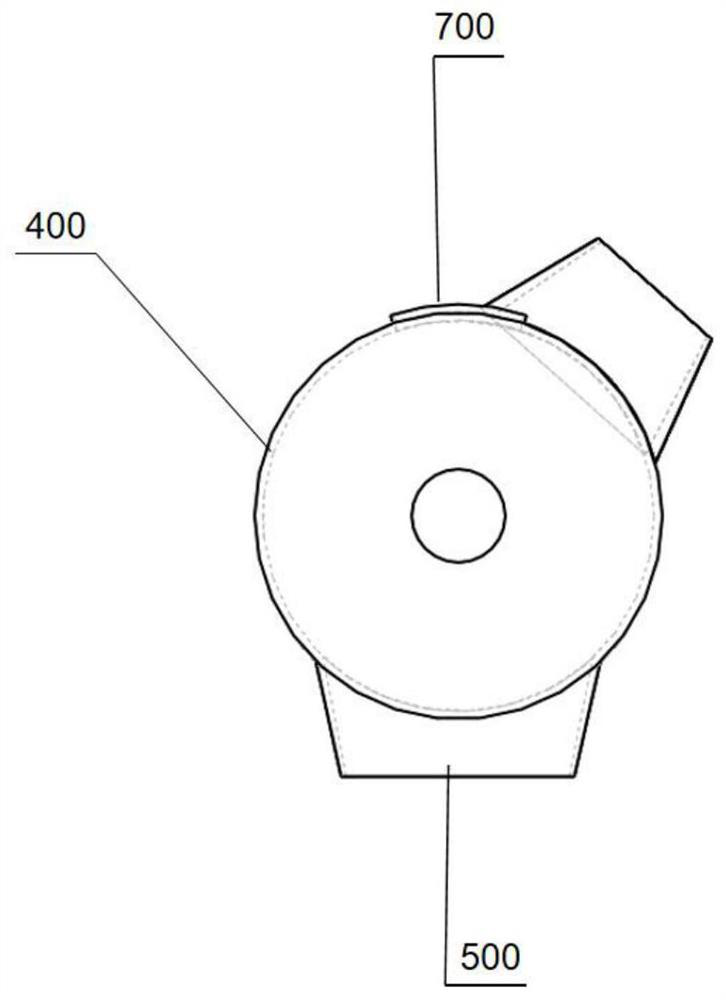

[0017] Such as figure 1 As shown, the present invention includes a reamer shaft (100), a three-wire right-handed helical blade (200), a left-handed helical blade, a cylinder (400), a feed port (500), a discharge port, and a cover plate (700), and the The reamer shaft (100), the three-wire right-handed helical blade (200), and the left-handed helical blade are arranged horizontally, and the three-wire right-handed helical blade (200) is welded on the reamer shaft (100), and the reamer shaft (100) is close to One side of the outer end is fixedly connected with the sprocket through a flat key, one end of the reamer shaft (100) is supported on the frame through a bearing with a vertical seat, and the other end of the reamer shaft (100) is supported on the frame through a bearing with a square seat Above, the three-line right-handed helical blade (200) and the left-handed h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com