Double-arm electric holding pole

A technology of electric power and holding poles, which is applied in the direction of building types, buildings, cranes, etc., can solve the problems of empty travel, lower lifting efficiency and stability, etc., and achieve the effect of improving lifting efficiency and high operating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

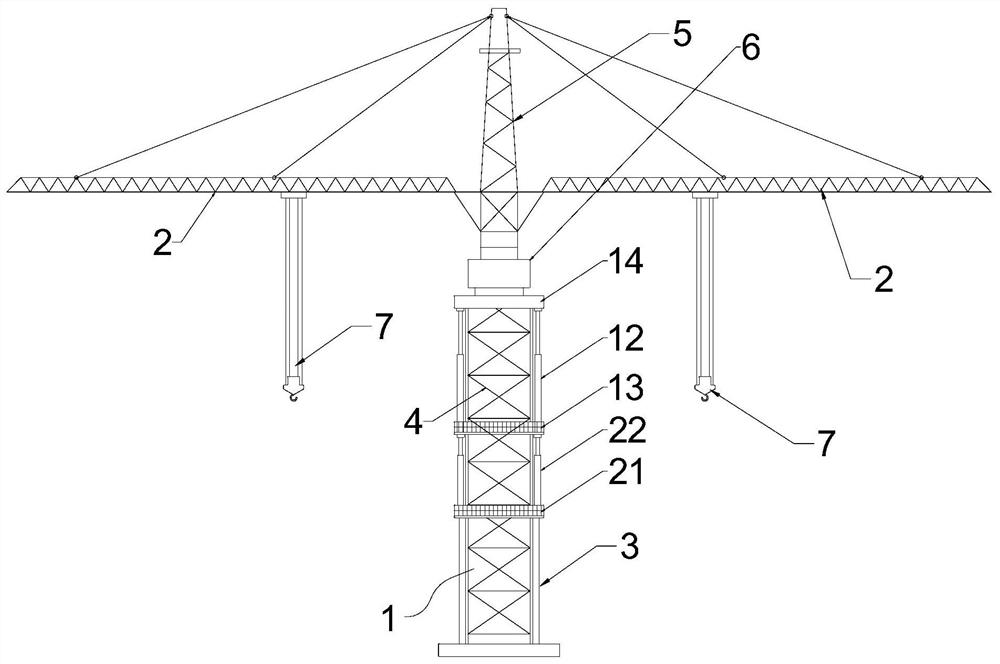

[0035] Such as Figure 1 to Figure 3 As shown, a double-arm electric holding pole includes: a tower body 1, a cantilever 2 and a lifting frame 3.

[0036] The tower body 1 includes a plurality of standard sections 4 fixedly connected sequentially along the longitudinal direction, the top of the standard section 4 is installed with a rotary joint seat 6, and the top of the rotary joint seat 6 is installed with an A-type tower 5; the left and right sides of the A-type tower 5 are installed symmetrically The cantilever 2 is horizontally suspended on the tower body 1 by a sling, and the hoist pulley block 7 is installed on the cantilever 2 to erect the pole.

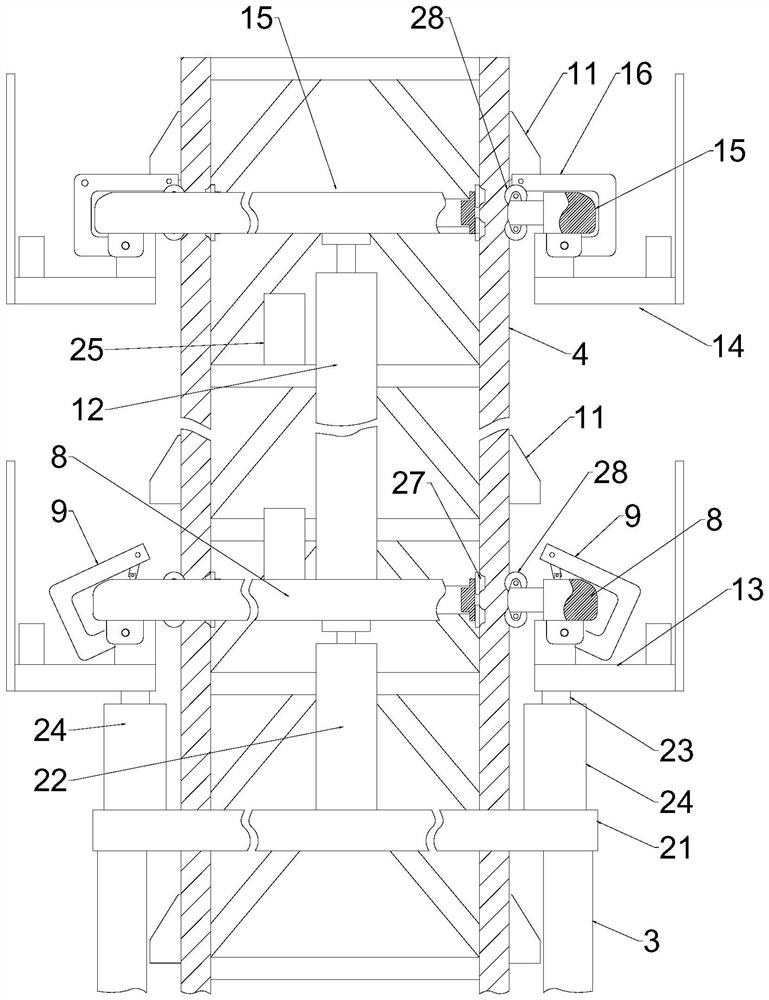

[0037] The inside of the hoisting frame 3 is provided with a frame room for accommodating the standard section 4. Lifting frame 3 is used for raising standard section 4 to empty the assembly space of next standard section below it, until a plurality of standard sections are affixed sequentially along the longitudinal direct...

Embodiment 2

[0046] In this embodiment, a stroke compensation mechanism is added on the basis of Embodiment 1. Before the return mode starts, the first lifting arm 9 has a small reserved distance from the nearest support block 11 above it, so that the first lifting arm 9 has enough The space can be turned inward without being blocked by the support block 11. In order to make the second workbench 14 release the standard joint in the return mode, the first jacking arm 9 can withstand the lower side of the standard joint in time, so that the standard joint does not slide due to the existence of the reserved distance. A stroke compensation mechanism is set on the frame, and the stroke compensation mechanism raises the first workbench 13 for a certain distance, so that the first lifting arm 9 is closely attached to the bottom of the support block 11, so as to realize the handover from the second workbench 14 without empty space Standard section 4, prevent the standard section from slipping.

...

Embodiment 3

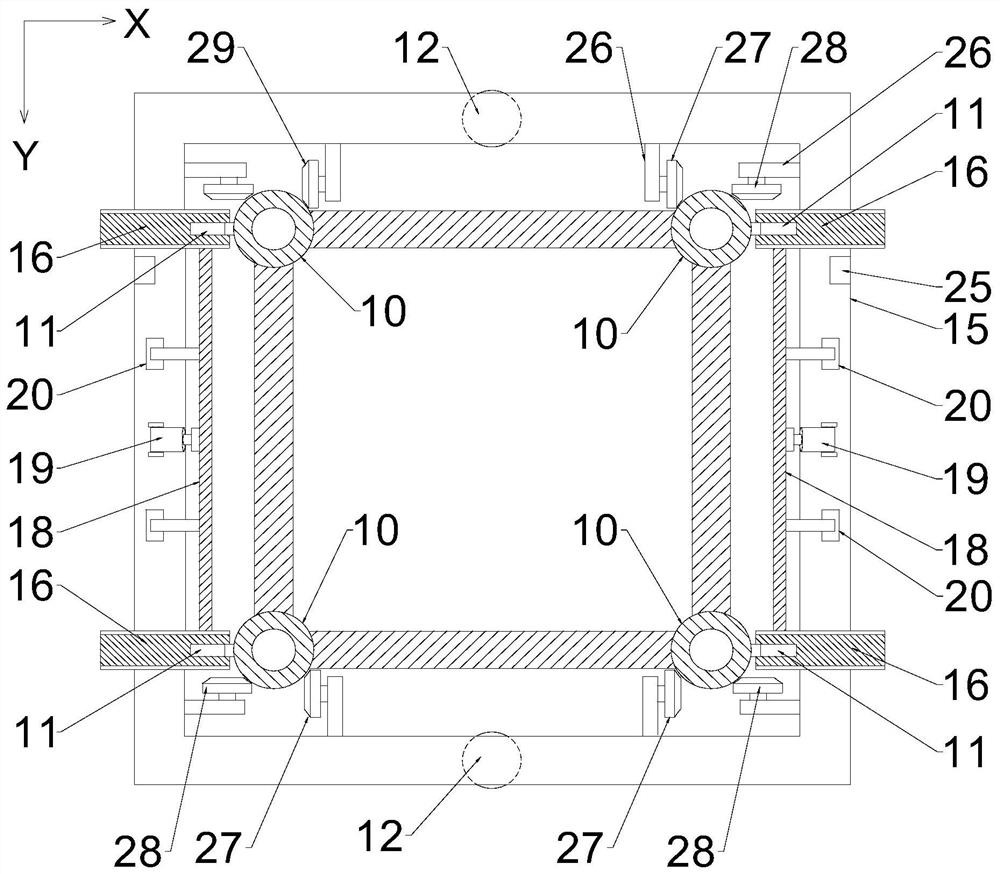

[0051] In this embodiment, on the basis of Embodiment 2, a guiding mechanism for fine-tuning the standard joint 4 is added. The first surrounding seat 8 and the second surrounding seat 15 are equipped with a guiding mechanism for adjusting the standard joint 4 moving upward. Guide along the longitudinal direction to prevent the slight deflection of the standard section 4 during the lifting process and affect the balance and support strength of the tower body.

[0052] The guiding mechanism comprises a supporting beam 26 and a guiding wheel set mounted on the supporting beam 26, and a plurality of supporting beams 26 are respectively welded and fixed on the first surrounding seat 8 and the second surrounding seat 15, and the first surrounding seat 8 and the second surrounding seat The surrounding seats 15 correspond to four sets of guide wheels, and the four sets of guide wheels are close to the four joint columns 10 of the standard section. During the rising process of the stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com