An emergency nitrogen charging system and control method for CDQ coke oven

A CDQ coke oven and control method technology, applied in coke ovens, coke cooling, furnace safety devices, etc., to achieve the effects of improving safety, prolonging service life, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

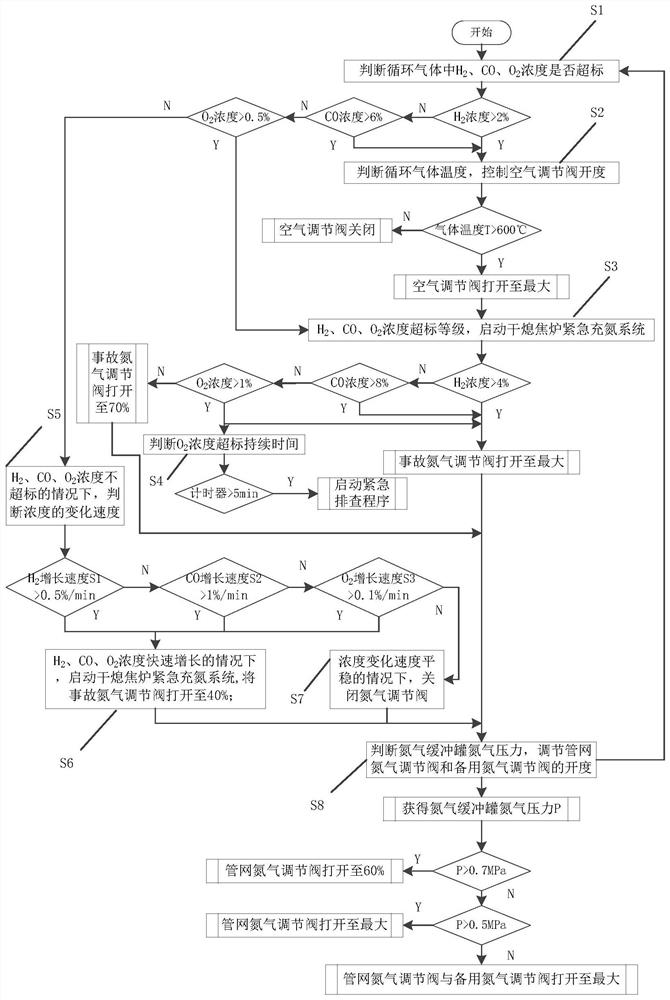

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing, the present invention is described in further detail:

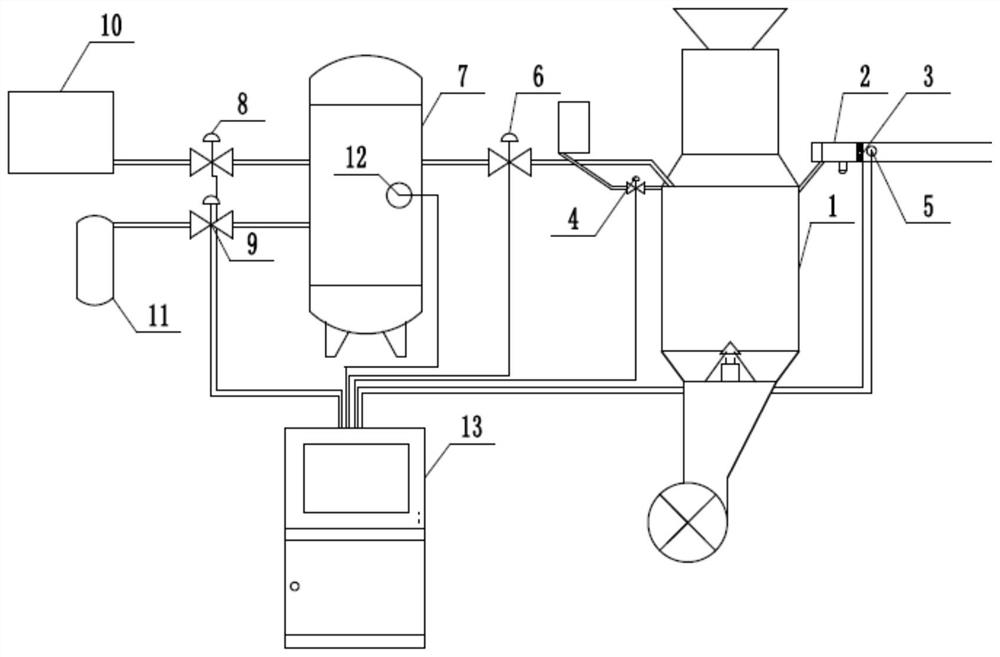

[0059] An emergency nitrogen charging system for CDQ coke ovens, including a CDQ coke oven 1 for cooling red coke and heating circulating gas, a gas circulation detection device for ensuring safe gas circulation, a nitrogen supply device for reducing the concentration of combustible gases, and real-time data collection CDQ control station DCS13 that controls the operation of the system;

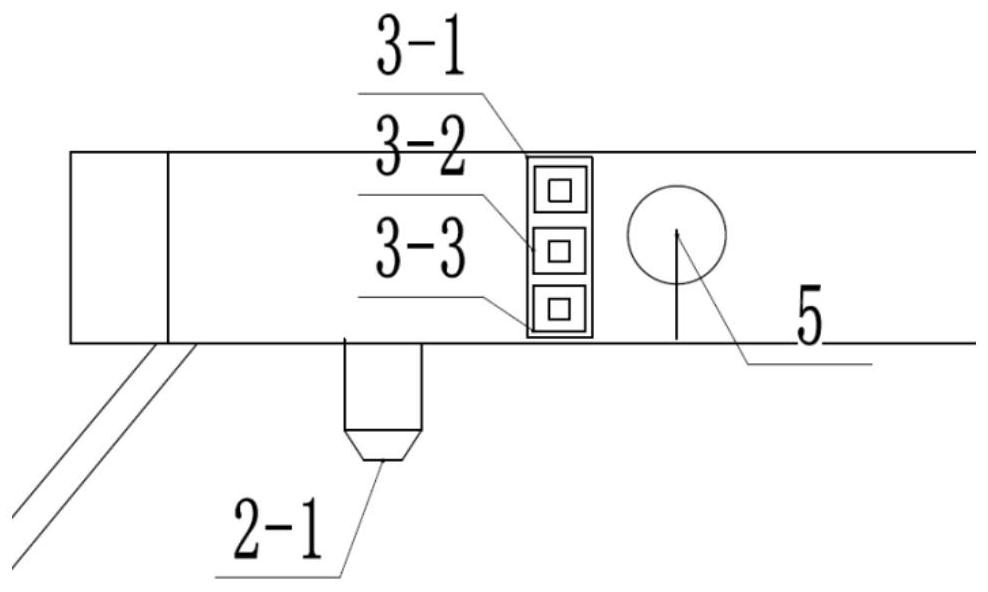

[0060] Such as figure 2 As shown, the gas circulation detection device includes an air regulating valve 4 for controlling the amount of air introduced into the CDQ coke oven 1, a circulating gas collecting pipe 2 for collecting the circulating gas and sending it to the inlet of the waste heat boiler, and a gas collecting pipe installed at the entrance of the circulating gas collecting pipe 2 respectively. Analyzer 3 and gas temperature sensor 5.

[0061] The nitrogen supply device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com