Equipment for extracting precious metal in automobile exhaust catalyst

A technology for extraction equipment and automobile exhaust, applied in solvent extraction, solid solvent extraction, chemical instruments and methods, etc., can solve the problems of prolonged extraction time, slow heat transfer, etc., to ensure quality, avoid leakage or secondary reaction, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

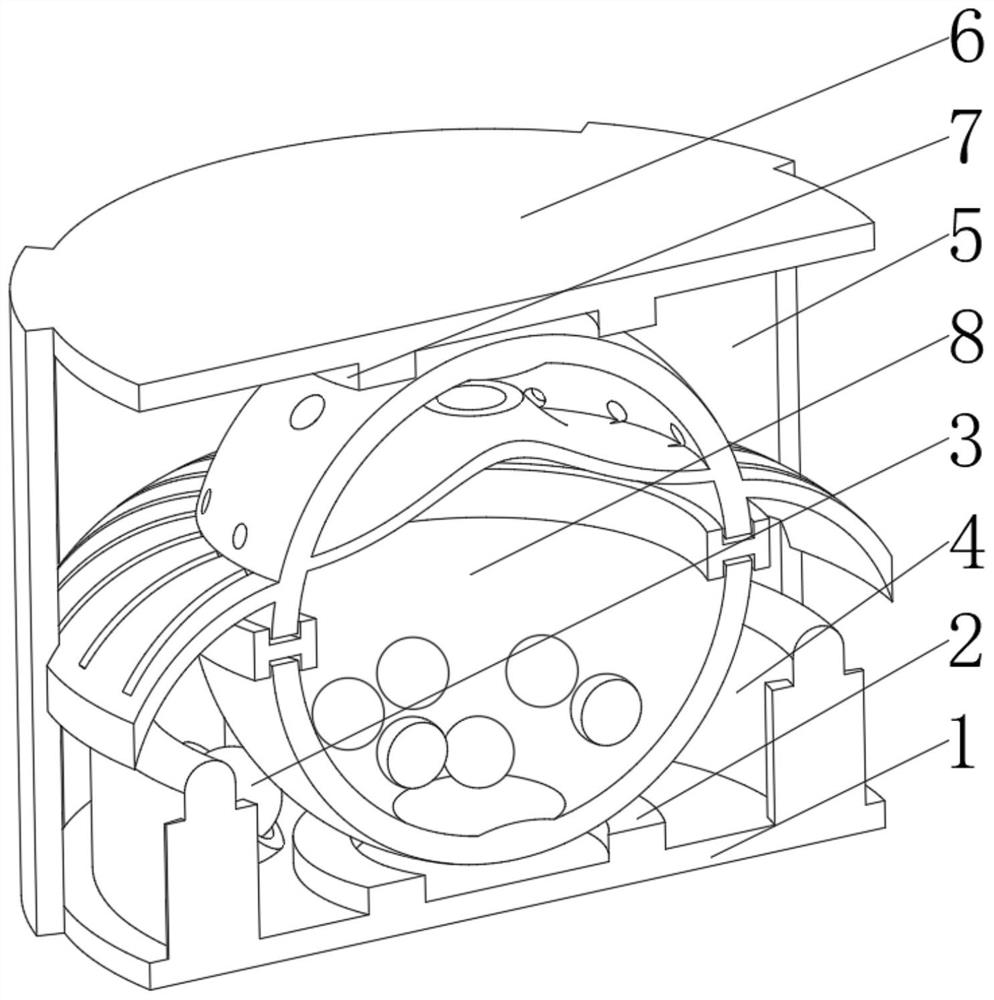

[0037] see Figure 1-2 , the present invention provides a technical solution: a kind of precious metal extraction equipment in automobile exhaust catalyst, specifically comprising:

[0038] Base plate 1, the base plate 1 has a circular plate body, and a magnetic ring 2 installed in the middle of the top of the circular plate body, and a supporting rotating ball 3 installed on the top of the circular plate body and outside the magnetic ring 2, and The energy ring plate 4 that is installed on the top of the circular plate body and is positioned at the outside of the supporting rotating ball 3, and the mounting frame plate 5 installed on the outer surface of the circular plate body, and the top cover 6 installed on the top of the mounting frame plate 5, and fixed on The matching magnetic ring 7 at the bottom of the top cover 6 and the extraction device 8 installed on the inner surface of the mounting frame plate 5 support and position the extraction device 8 through the design of...

Embodiment 2

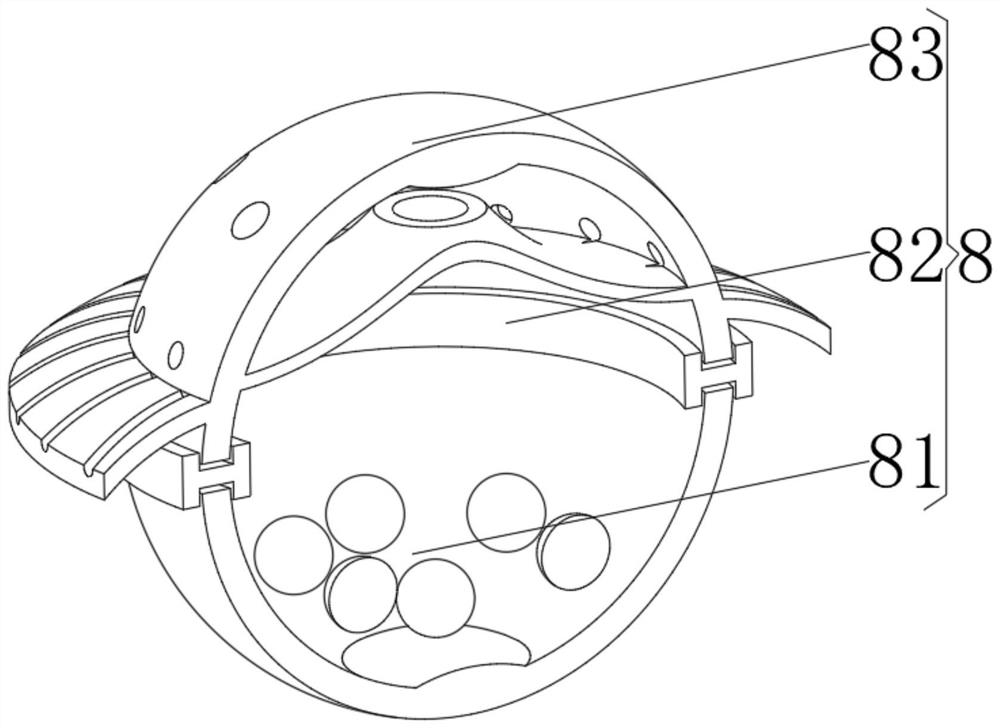

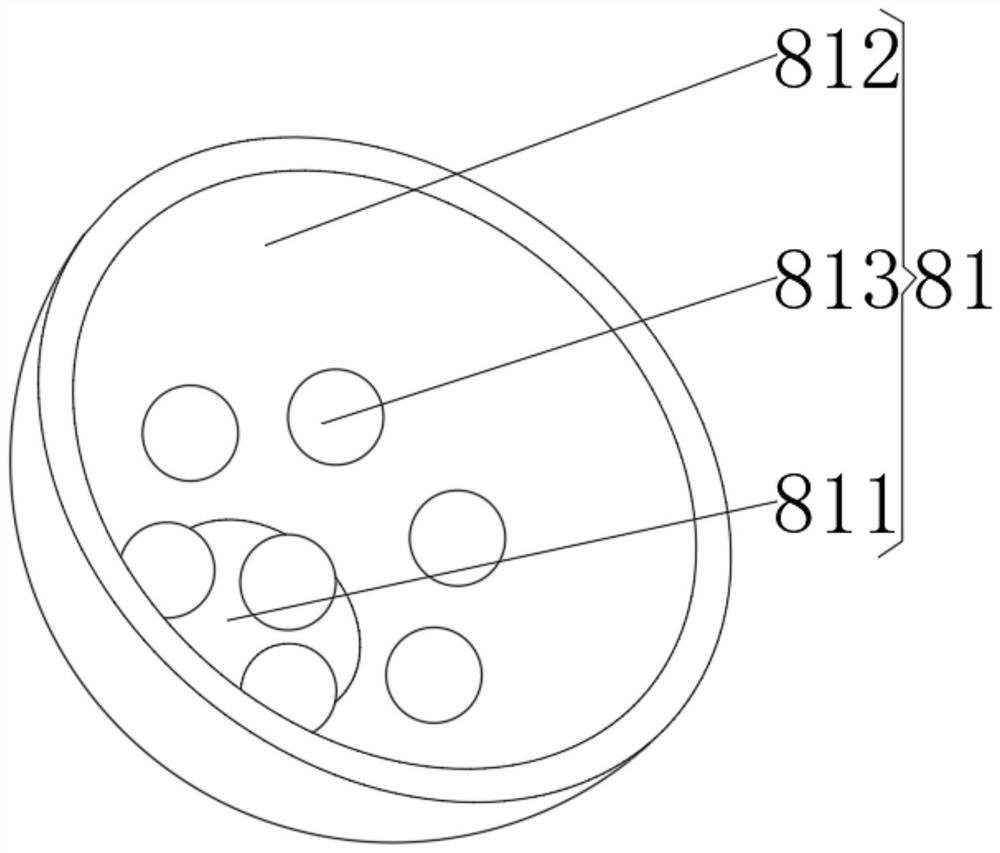

[0044] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the extraction hemisphere 81 includes:

[0045] A convex base 811, the convex base 811 has a spherical body, a hemisphere 812 installed on the outer surface of the spherical body, and a catalytic ball 813 installed in the inner cavity of the hemisphere 812. Through the design of the catalytic ball 813, they can move and collide with each other during the extraction, so as to promote the mutual flow of the extraction raw liquids, refine the raw extraction liquids, and improve the speed and efficiency of extraction.

[0046] The catalytic ball 813 includes:

[0047] Inert shell 8131, the inert shell 8131 has a spherical main body, and a cross thermal column 8132 installed on the inner surface of the inert shell 8131, and an eddy current coil 8133 installed on the outer surface of the cross thermal column 8132, and a net arranged on the outer surface of the eddy current coil...

Embodiment 3

[0051] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the exhaust device 83 includes:

[0052] The ring plate 831 is installed, and the ring plate 831 has an arc panel body, and a shunt groove 832 provided on the top of the arc panel body, and a spherical top cover 833 installed on the inner surface of the arc panel body, and a spherical top cover 833 provided on the top of the arc panel body The air hole 834 of the spherical top cover 833 is provided with a liquid discharge hole 835 on the side of the arc panel body near the top of the spherical top cover 833, and the spherical baffle plate 836 installed on the top of the inner surface of the spherical top cover 833 is installed on the spherical top cover 833 Concentrating deflector 837 at the bottom of the inner surface. Through the design of the spherical baffle 836 and the flow-concentrating guide plate 837, the airflow can be intercepted slowly, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com