Rapid stoping method for pre-treating hard rock mass invaded by coal face in advance

A technology for coal mining face and pretreatment, which is applied in the fields of mining fluids, ground mining, and earth-moving drilling, etc., can solve problems such as damage to the roof of the working face, support of the working face, instrument damage, and restrict the high-quality development of the mine, and reduce the The effect of destroying, enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

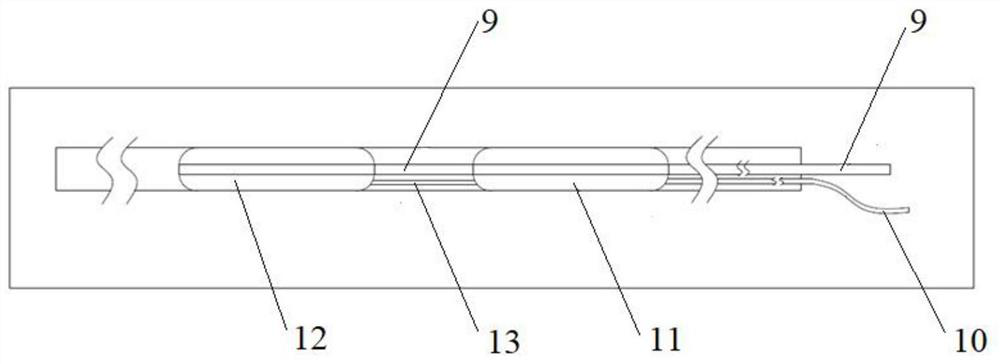

Method used

Image

Examples

Embodiment 1

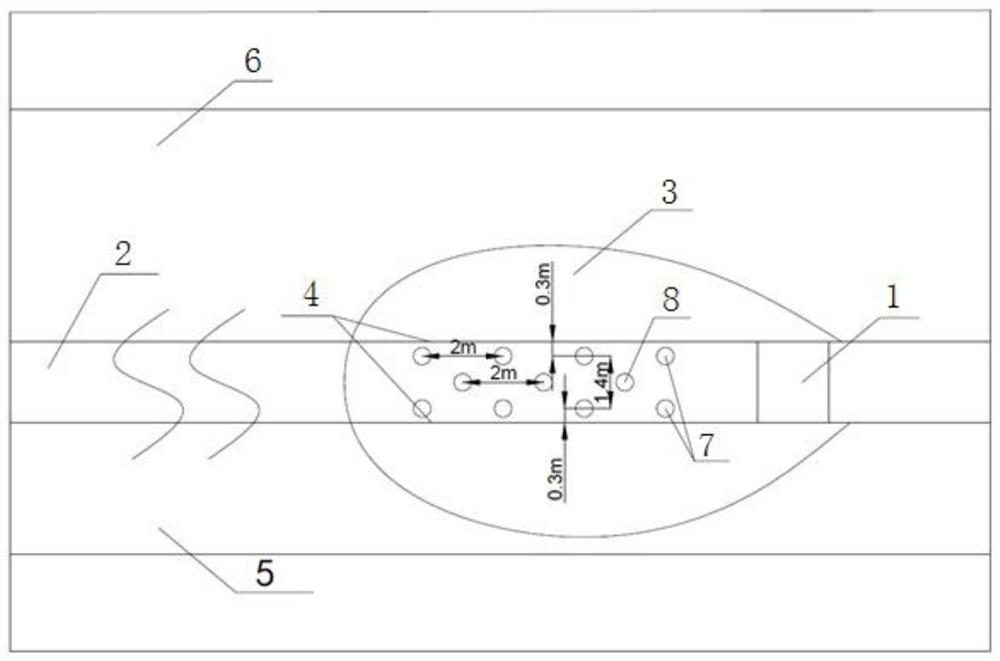

[0046] In this embodiment, the mining of a certain mine working face is taken as the engineering background, and the coal seam conditions of the working face are as follows: the coal seam is mainly bright coal, with middle mirror and thin strips of dark coal. The structure of the coal seam is simple, the lower part of the coal seam contains gangue, the thickness of the gangue is 0.1m~0.2m, and there is a 0.2m~0.3m thick powder coal seam at the bottom. The thickness of the coal seam is between 1.4m and 2.6m, with an average thickness of 2.0m, which is a relatively stable coal seam.

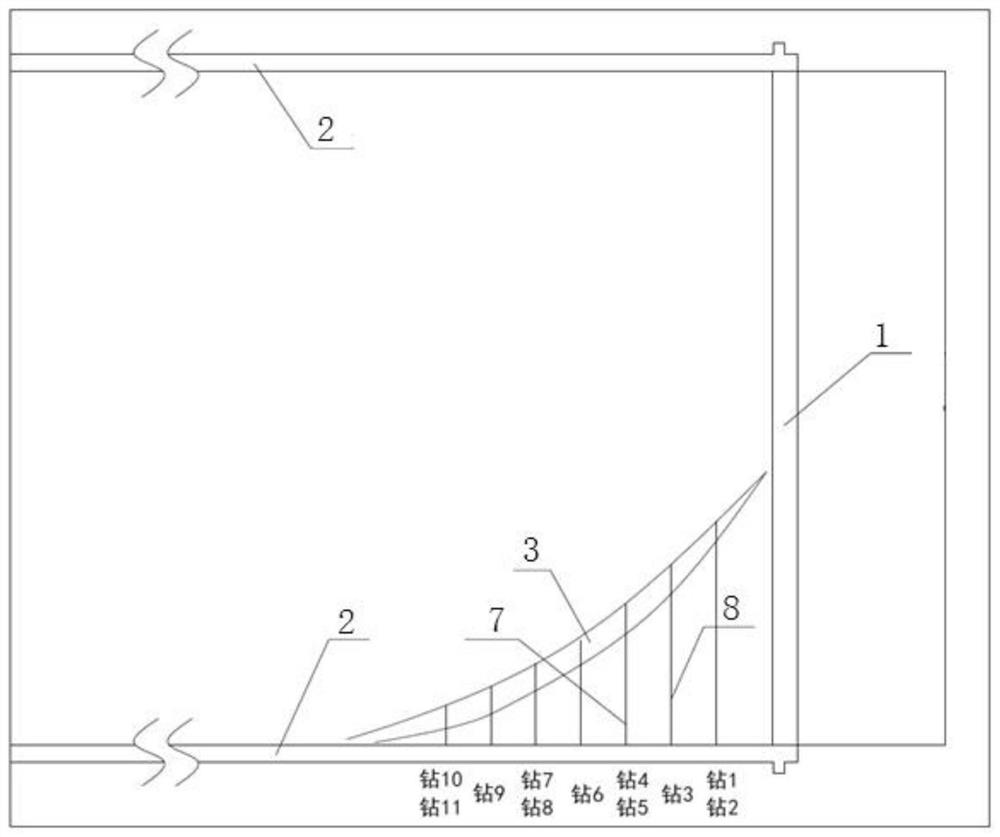

[0047] Such as figure 1 As shown, the working face dips with an average length of 186m, and develops faults at the lower end of the cut, which are normal faults, with a strike of 248°, a dip of 68°, a dip of 32°, and a drop of 3.8m. The impact of fault intrusion into the hard rock mass is 22m in direction and 134m in direction, which has a great influence on the rapid recovery of the working face....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com