Brayton cycle system modeling method based on nonlinear programming

A nonlinear programming and cyclic system technology, applied to steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as inability to deal with fuzzy constraints, difficulty in ensuring stability, and taking up a lot of time, so as to facilitate performance comparison and calculation steps The effect of simplifying, streamlining the modeling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

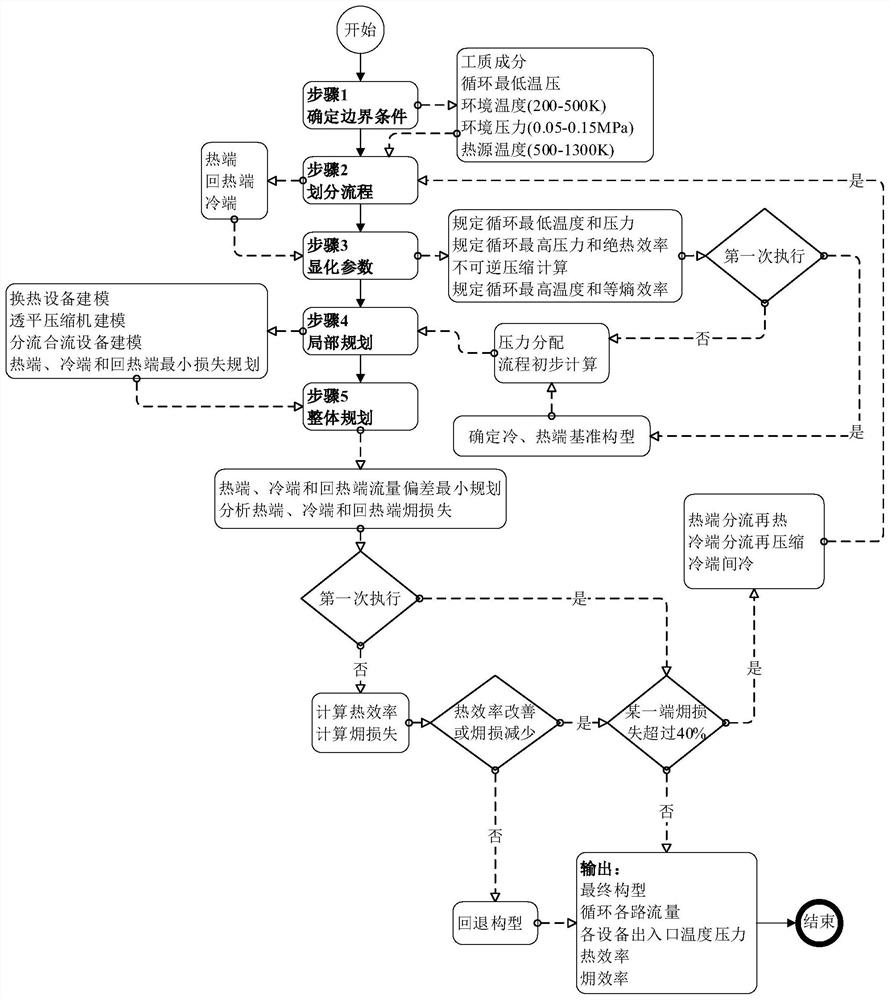

[0057] Attached below figure 1 , taking a supercritical carbon dioxide Brayton cycle system applied to a small-scale fluoride-salt cooled high-temperature reactor as an example, the specific implementation of the method of the present invention will be described in detail.

[0058] The modeling method of Brayton cycle system based on nonlinear programming includes five steps: determining boundary conditions, dividing process, manifesting parameters, local planning and overall planning:

[0059] Step 1. Determine the boundary conditions: determine the composition of the working fluid, the minimum temperature pressure of the cycle, the ambient temperature, the ambient pressure, and the heat source temperature; the ambient temperature range is limited to 288.15K; the ambient pressure is limited to 0.1MPa, and the heat source temperature is limited to 923-973K;

[0060] Step 2. Divide the process: Divide the Brayton cycle system into hot end, heat return end and cold end according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com