Leveling and focusing method for photoetching machine workpiece table in consideration of system coupling characteristics

A technology of leveling and focusing and lithography machine, which is applied in the direction of photomechanical equipment, microlithography exposure equipment, and photoplate making process of pattern surface, etc. Axis, leveling and focusing speed slow down, etc., to reduce the loss of leveling and focusing precision, facilitate individual control, and increase the final leveling and focusing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

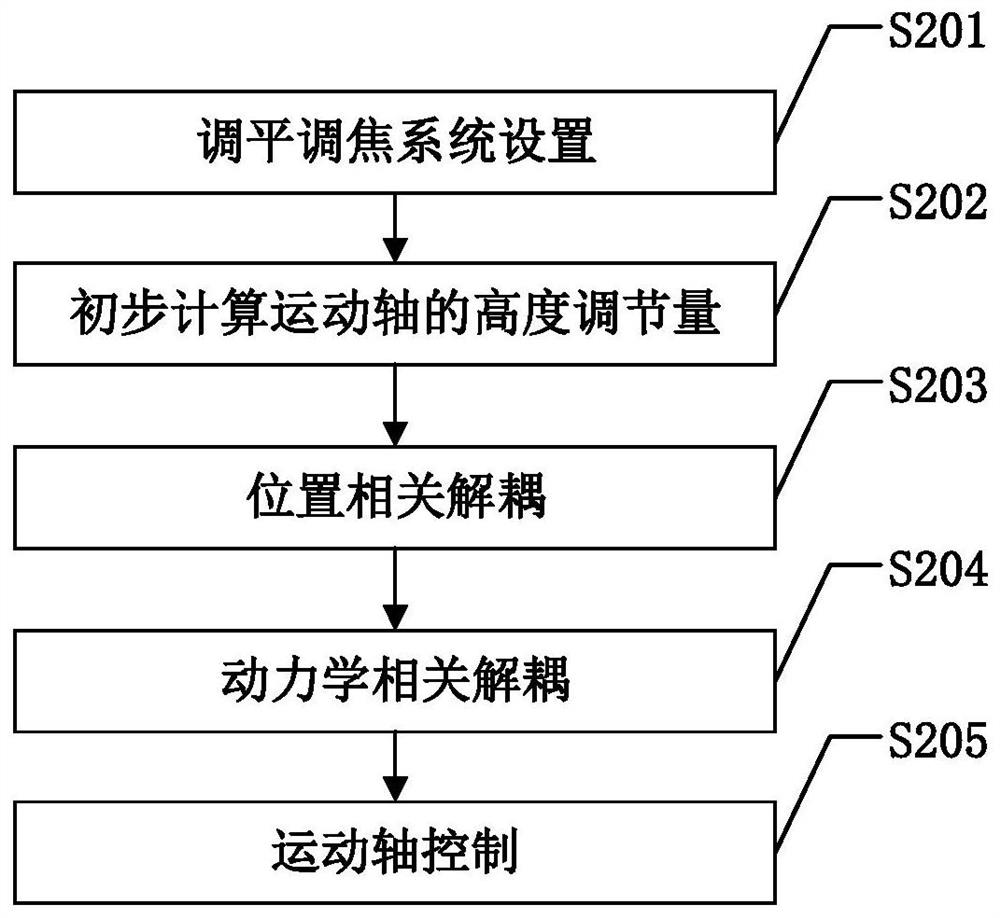

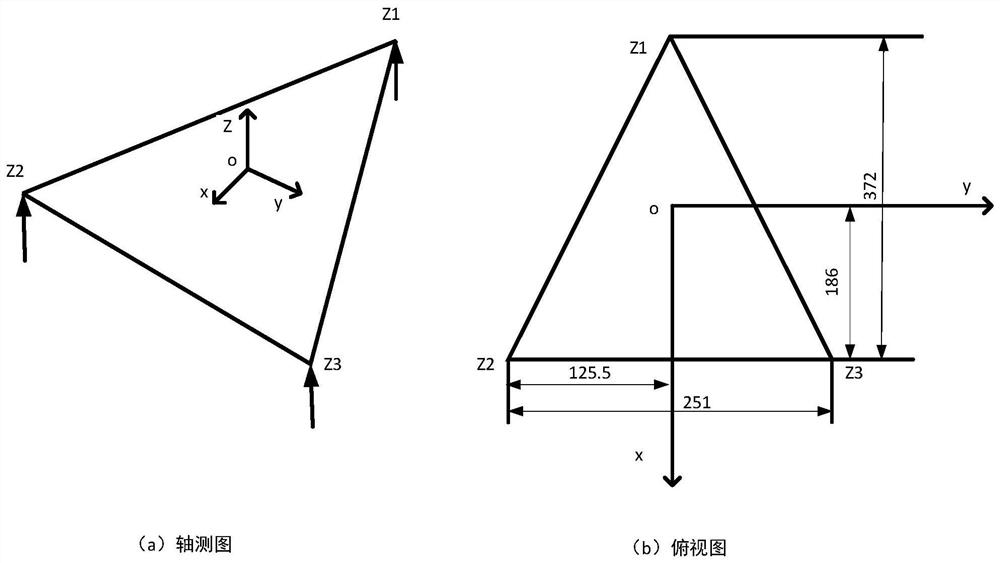

[0034] In order to better realize the technical solution of the present invention, the principle on which the present invention is based is briefly described first.

[0035] For the lithography machine workbench using the three-point leveling method, its control system is a 3-input and 3-output system, and its input is the defocus amount z of the workbench, and the inclination angle θ of the workbench in the x-axis direction x , The inclination angle θ of the table in the y-axis direction y , the output is the control index of the three motion axes. It can be seen that the control system belongs to a typical MIMO motion system. The present invention converts this complex MIMO system into three independent SISO systems by analyzing and modeling the internal coupling mechanism, and then controls each logical axis , so that the control parameters of each motion axis can be adjusted independently.

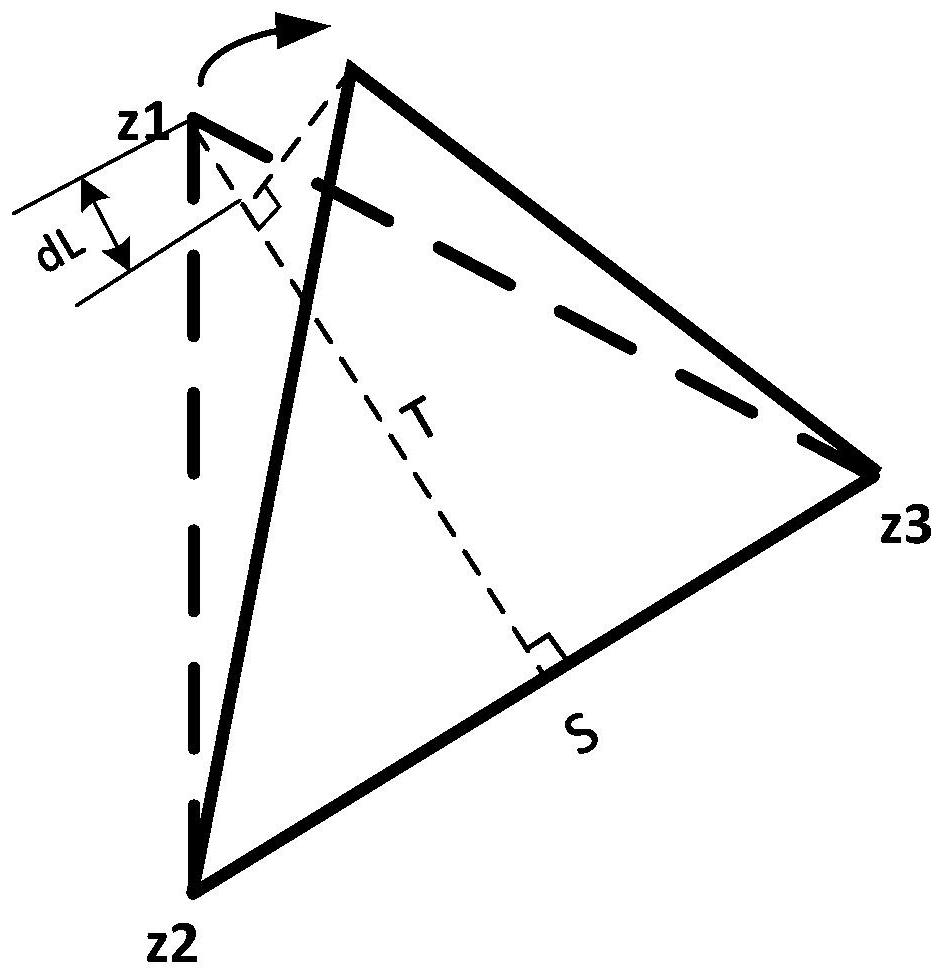

[0036] The coupling of the workbench control system mainly includes two types: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com