Motor heat dissipation equipment for axial flow fan

A technology of motor heat dissipation and axial flow fan, which is applied to mechanical equipment, axial flow pumps, electromechanical devices, etc., can solve problems such as increased maintenance times, limited heat dissipation, and severe wear of bearings and other components, and achieve the effect of accelerating cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

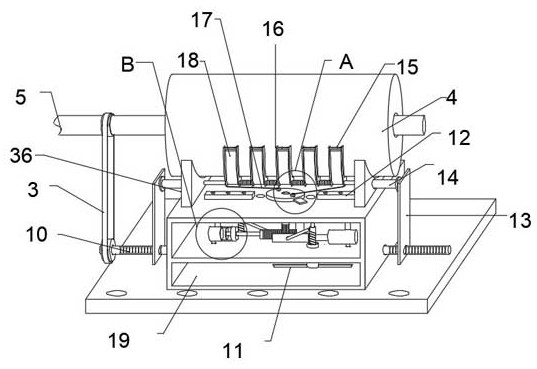

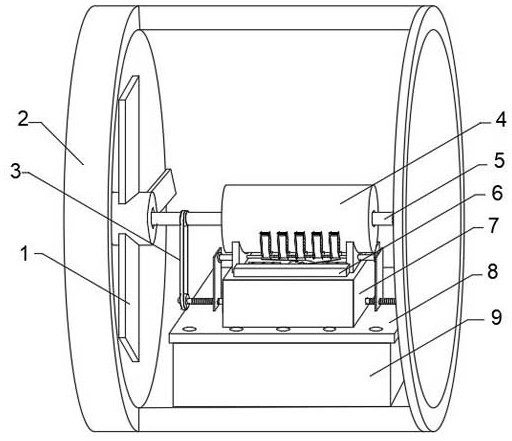

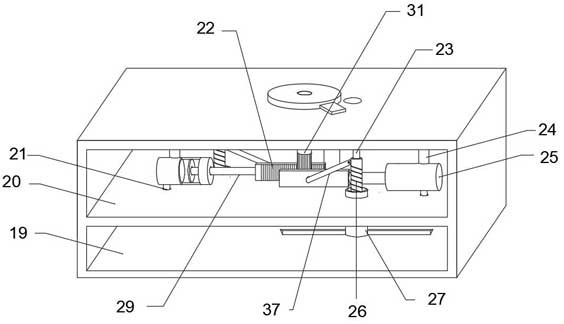

[0031] refer to Figure 1-5 , a motor heat dissipation device for an axial flow fan, the motor heat dissipation device for an axial flow fan includes:

[0032] The installation cylinder 2 and the fixed block 9 fixedly connected inside the installation cylinder 2, the fixed block 9 is used to support and fix the motor cooling equipment;

[0033] Drive part, drive part comprises cooling chamber 7, support plate 36, drive motor 4, two support plates 36 are respectively fixedly connected to the two ends of the upper surface of heat dissipation chamber 7, and water storage chamber 19 and placement chamber are respectively opened in heat dissipation chamber 7 20. The heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com